Abstract

The fracture of the surrounding rock in deep hard rock engineering is influenced by the stress path during excavation. Taking the stress path as the only variable, a true triaxial experimental system was used to study the loading–unloading stress path during excavation and the loading stress path with constant stress state after excavation, and combined with acoustic emission, 3D laser scanning and SEM to investigate the differential mechanisms of the two stress paths on the strength, energy storage and fracture of the rock. The results show that the strength, deformation and ultimate energy storage capacity of the rock under the loading−unloading stress path are greater than those under the loading stress path with constant stress state. Compared with the loading stress path with constant stress state, with the loading−unloading stress path, the rock fractures are more fragmented, the failure angles are slightly smaller, and the development of shear cracks is delayed, occurring closer to rock failure. This is due to the influence of the true triaxial stress state on rock fracture expansion. The changing direction and location of rock fracture expansion under the loading−unloading stress path inhibits crack penetration, which in turn delays the development of shear cracks. The effect of the stress path is influenced by the rate of loading and unloading; the greater the rate of loading and unloading of the rock is, the greater the strength and ultimate energy storage of the rock. Finally, the evolution characteristics of the tensile and shear cracks formed in the rock under the loading−unloading stress paths during excavation provide new understanding for the prevention and control of deep engineering hazards.

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

References

Aggelis DG (2011) Classification of cracking mode in concrete by acoustic emission parameters. Mech Res Commun 38(3):153–157

Aggelis DG, Shiotani T, Papacharalampopoulos A, Polyzos D (2012) The influence of propagation path on elastic waves as measured by acoustic emission parameters. Struct Control Hlth Monit 11(3):359–366

Bai Q, Tibbo M, Nasseri MHB, Young RP (2019) True triaxial experimental investigation of rock response around the mine-by tunnel under an in situ 3D stress path. Rock Mech Rock Eng 52:3971–3986

Cai WQ, Zhu HH, Liang WH (2022) Three-dimensional tunnel face extrusion and reinforcement effects of underground excavations in deep rock masses. Int J Rock Mech Min Sci 150:104999

Cai WQ, Zhu HH, Liang WH (2022) Three-dimensional stress rotation and control mechanism of deep tunneling incorporating generalized Zhang-Zhu strength-based forward analysis. Eng Geol 308:106806s

Carpinteri A, Lacidogna G, Accornero F, Mpalaskas AC, Matikas TE, Aggelis DG (2013) Influence of damage in the acoustic emission parameters. Cement Concrete Comp 44(44):9–16

Chang SH, Lee CI (2004) Estimation of cracking and damage mechanisms in rock under triaxial compression by moment tensor analysis of acoustic emission. Int J Rock Mech Min Sci 41:1069–1086

Chen WZ, Lü SP, Guo XH, Qiao CJ (2010) Unloading confining pressure for brittle rock and mechanism of rock burst. Chin J Geotech Eng 32(6):963–969 (in Chinese)

Cheng Y, Wong L, Zou C (2015) Experimental study on the formation of faults from en-echelon fractures in Carrara Marble. Eng Geol 195:312–326

Du K, Liu M, Yang CZ, Tao M, Feng FK, Wang SF (2021) Mechanical and acoustic emission (AE) characteristics of rocks under biaxial confinements. Appl Sci 11(2):769

Eberhardt E (2001) Numerical modelling of three-dimension stress rotation ahead of an advancing tunnel face. Int J Rock Mech Min Sci 38:499–518

Eberhardt E, Stead D, Stimpson B (1999) Quantifying progressive pre-peak brittle fracture damage in rock during uniaxial compression. Int J Rock Mech Min Sci 36(3):361–380

Feng XT, Kong R, Yang CX, Zhang XW, Wang ZF, Han Q, Wang G (2020) A three-dimensional failure criterion for hard rocks under true triaxial compression. Rock Mech Rock Eng 53(1):103–111

Feng XT, Kong R, Zhang XW, Yang CX (2019) Experimental study of failure differences in hard rock under true triaxial compression. Rock Mech Rock Eng 52:2109–2122

Feng XT, Xu H, Yang CX, Zhang XW, Gao YH (2020) Influence of loading and unloading stress paths on the deformation and failure features of jinping marble under true triaxial compression. Rock Mech Rock Eng 53(1):3287–3301

Feng XT, Zhang XW, Kong R, Wang G (2016) A novel mogi type true triaxial testing apparatus and its use to obtain complete stress–strain curves of hard rocks. Rock Mech Rock Eng 49(5):1649–1662

Gao H, Zheng YR, Feng XT (2007) Study on energy yield criterion of geomaterials. Chin J Rock Mech Eng 26(12):2437–2443 (in Chinese)

Graham CC, Stanchits S, Main IG, Dresen G (2010) Comparison of polarity and moment tensor inversion methods for source analysis of acoustic emission data. Int J Rock Mech Min Sci 47:161–169

Griffith AA (1921) The phenomena of rupture and flow in solids. Philos Trans R Soc Lond 221(582–593):163–198

Gu LJ, Feng XT, Kong R, Yang CX (2023) Effect of principal stress direction interchange on the failure characteristics of hard rock. Int J Rock Mech Min Sci 164:105365

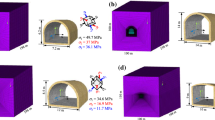

Gu LJ, Feng XT, Kong R, Yang CX, Han Q, Xia YL (2022) Excavation stress path induced fracturing mechanism of hard rock in deep tunnel. Rock Mech Rock Eng 56(3):1779–1806

Guo Y, Wang L, Chang X (2019) Study on the damage characteristics of gas-bearing shale under different unloading stress paths. PLoS ONE 14(11):e0224654

Haimson B (2012) True triaxial testing reveals hitherto unknown rock mechanical properties. True Triaxial Test Rocks 4:159

Han L, He Y, Zhang H (2016) Study of rock splitting failure based on griffith strength theory. Int J Rock Mech Min Sci 83:116–121

Hashiba K, Fukui K (2015) Index of loading-rate dependency of rock strength. Rock Mech Rock Eng 48(2):859–865

He MC, Li JY, Liu DQ, Li K, Ren FQ (2021) A novel true triaxial apparatus for simulating strain bursts under high stress. Rock Mech Rock Eng 54:759–775

Hu X, Su G, Chen G, Mei S, Feng X, Mei G, Huang X (2019) Experiment on rockburst process of borehole and its acoustic emission characteristics. Rock Mech Rock Eng 52(3):783–802

Huang RQ, Wang XN, Chan LS (2001) Triaxial unloading test ofrocks and its implication for rock burst. Bull Eng Geol Environ 60(1):37–41

Jang HS, Kang SS, Jang BA (2014) Determination of joint roughness coefficients using roughness parameters. Rock Mech Rock Eng 47(6):2061–2073

Kaiser PK, Yazici S, Maloney S (2001) Mining-induced stress change and consequences of stress path on excavation stability – a case study. Int J Rock Mech Min Sci 38:167–180

Kazerani T (2013) Effect of micromechanical parameters of microstructure on compressive and tensile failure process of rock. Int J Rock Mech Min Sci 64:44–55

Kong R, Tuncay E, Ulusay R, Zhang XW, Feng XT (2021) An experimental investigation on stress-induced cracking mechanisms of a volcanic rock. Eng Geol 280:105934

Kovari K, Tisa A, Einstein HH, Franklin JA (1983) Suggested methods for determining the strength of rock materials in triaxial compression: revised version. Int J Rock Mech Min Sci 20(6):283–290

Li XB, Du K, Li D (2015) True triaxial strength and failure modes of cubic rock specimens with unloading the minor principal stress. Rock Mech Rock Eng 48(6):2185–2196

Li TB, Wang LS (1993) An experimental study on deformation and failure features of a basalt under unloading condition. Chin J Rock Mech Eng 12(4):321–327 (in Chinese)

Li BX, Zhang WM, Xue YG, Kong R, Zhu WS, Yu YH, Chen YJ (2022) An image segmentation-based method for quantifying the rock failure mechanism under true triaxial compression. Int J Rock Mech Min Sci 158:105195

Liu G, Chen Y, Du X, Xiao P, Liao SM, Azzam R (2021) Investigation of microcrack propagation and energy evolution in brittle rocks based on the voronoi model. Materials 14(9):2108

Martin D, Kaiser PK, Tannant D (1999) Stress path and failure around mine openings. In: Proceedings of the 9th ISRM international congress on rock mechanics, vol 1. Balkema, Paris, pp 311–315

Mohr O (1900) Welche Umsta¨nde bedingen die Elastizita¨ tsgrenze und den Brucheines Materials. VDI-Zeitschrift 44:1524

Ohno K, Ohtsu M (2010) Crack classification in concrete based on acoustic emission. Constr Build Mater 24(12):2339–2346

Pao YH (1978) Theory of acoustic emission. In: Transactions of the 23rd Conference of Army Mathematicians p 389

Qiu SL, Feng XT, Xiao JQ, Zhang CQ (2014) An experimental study on the pre-peak unloading damage evolution of marble. Rock Mech Rock Eng 47(2):401–419

Shahidan S, Pulin R, Bunnori NM, Holford KM (2013) Damage classification in reinforced concrete beam by acoustic emission signal analysis. Constr Build Mater 45:78–86

Singh M, Singh B (2012) Modified Mohr-Coulomb criterion for non-linear triaxial and polyaxial strength of jointed rocks. Int J Rock Mech Min Sci 51:43–52

Sotirios JV (1999) Acoustic Emission: Standards and Technology Update. Philadelphia, PA: ASTM International STP–1353

Stacey TR (1981) A simple extension strain criterion for fracture of brittle rock. Int J Rock Mech Min Sci & Geomech Abstr 18(6):469–474

Tang Y, Zhang H, Xu J, Okubo S, Liu XR (2021) Loading rate dependence of rock strength under triaxial compression. Front Earth Sci 9:728366

Wang SR, Chen YL, Xiong M, Du X, Liu GL, Fernandez-Steeger T (2021) The mechanism of fracture and damage evolution of granite in thermal environment. Materials 14(23):7234

Wang ZF, Feng XT, Yang CX, Zhou YY, Xu H, Han Q, Gao YH (2020) Experimental investigation on fracturing process of marble under biaxial compression. J Rock Mech Geotech Eng 12(5):943–959

Wang Y, Nguyen NHT, Zhao L (2021) Micromechanical study on hard rock strainburst using the discrete element method. Tunn Undergr Sp Tech 109:103793

Wang S, Wang L, Tian J, Fan H, Jiang C, Ding K (2022) An experimental study on the effects of true triaxial loading and unloading stress paths on the mechanical properties of red sandstone. Minerals 12:204

Wang Y, Xu J (2022) Particle flow analysis of acoustic emission features of rock under rock burst stress path. Geofluids 17:6534034

Xiao F, Jiang DY, Wu F, Chen J, Zhang JZ, Liu W (2021) Deformation and failure characteristics of sandstone subjected to true–triaxial unloading: an experimental and numerical study. Fatigue Fract Eng M 44(7):1862–1882

Xu H, Feng XT, Yang CX, Zhang XW, Zhou YY, Wang ZF (2019) Influence of initial stresses and unloading rates on the deformation and failure mechanism of Jinping marble under true triaxial compression. Int J Rock Mech Min Sci 117:90–104

Xu DP, Huang X, Jiang Q, Li SJ, Zheng H, Qiu SL, Xu HS, Li YH, Li ZG, Ma XD (2021) Estimation of the three-dimensional in situ stress feld around a large deep underground cavern group near a valley. J Rock Mech Geotech 13:529–544

Yu MH, He LN, Song LY (1985) Double shear stress strength theory and its extension. Scientia Sinica (Mathematica) 12:1113–1120 (in Chinese)

Zhang Y, Feng XT, Zhang XW, Wang ZF, Mostafa S, Yang CX (2019) A novel application of strain energy for fracturing process analysis of hard rock under true triaxial compression. Rock Mech Rock Eng 52(11):4257–4272

Zhang Y, Feng XT, Zhang X, Wang ZF, Mostafa S, Yang CX, Kong R, Zhao J (2019) Strain energy evolution characteristics and mechanisms of hard rocks under true triaxial compression. Eng Geol 260:105222

Zhao J, Feng XT, Zhang XW, Zhang Y, Yang CX (2018) Brittle-ductile transition and failure mechanism of Jinping marble under true triaxial compression. Eng Geol 232:160–170

Zheng Z, Feng XT, Yang CX, Zhang XW, Li SJ, Qiu SL (2020) Post-peak deformation and failure behaviour of Jinping marble under true triaxial stresses. Eng Geol 265:105444

Zheng Z, Tang H, Zhang Q, Pan PZ, Zhang XW, Mei GX, Liu ZB, Wang W (2023) True triaxial test and PFC3D-GBM simulation study on mechanical properties and fracture evolution mechanisms of rock under high stresses. Comput Geotech 154:105136

Acknowledgements

The authors gratefully acknowledge financial support from the National Natural Science Foundation of China under Grant Nos. 51839003 and 41827806, Liao Ning Revitalization Talents Program under Grant No. XLYCYSZX1902, and project funded by the China Postdoctoral Science Foundation under Grant No. 2021M700728. The authors thank Mr. Benguo He, Mr. Xufeng Liu and Ms. Xinyue Wang for their great assistance. The authors also thank the journal editors and anonymous reviewers for their valuable suggestions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gu, L., Feng, XT., Kong, R. et al. Influence of excavation stress paths on failure feature of deep hard rocks. Acta Geotech. 19, 1107–1128 (2024). https://doi.org/10.1007/s11440-023-02003-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-023-02003-2