Abstract

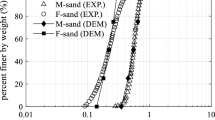

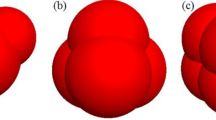

Because of the limitations on laboratory space and testing apparatus, such as the load capacity, the mechanical properties of prototype rockfill materials are generally obtained from scaled-down samples. It has been generally accepted that the underestimation of the high rockfill dam deformation is primarily due to the scale effect of rockfill materials, i.e., there are differences between the mechanical properties of prototype materials and scaled-down samples. Recent experimental studies again demonstrate that the scale effect of rockfill materials consisting of sandy gravels and blasting rocks is different, and the underlying mechanism is still unclear. This study uses the discrete element method (DEM) to investigate the microscopic mechanism of the scale effect of sandy gravel material collected from Dashixia rockfill dam in China. The sandy gravel material composed of rounded gravel and pebbles is modeled as an assembly of spheres, and the rolling resistance at particle contacts considers the slight particle non-sphericity. The DEM input parameters are calibrated and verified by a series of single-particle crushing tests, angle of repose tests, and triaxial compression tests. The DEM simulations of triaxial compression tests are performed on samples with different particle crushing strengths and particle size distributions (PSD). Particle breakage weakens the shear strength and considerably lowers the deformation modulus of sandy gravel material. On the contrary, the widening of PSD has a significant effect on the force transmission structure, which is manifested as the increase in contact force and higher mobilization of frictional force at contacts, thus promoting the bulk resistance to deformation. The scale effect of sandy gravel material results from the competition between these two factors. As to the rounded gravel and pebbles studied here, the scale effect is dominated by the widening of PSD, which is confirmed by the increase in the deformation modulus and shear strength with an increase in maximum particle size and size span.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this article.

References

Alonso EE, Oldecop L, Pinyol NM (2009) Long term behaviour and size effects of coarse granular media. Mech Nat Solids 255–282

Azéma E, Linero S, Estrada N, Lizcano A (2017) Shear strength and microstructure of polydisperse packings: the effect of size span and shape of particle size distribution. Phys Rev E 96:1–10

Azéma E, Radjaï F (2012) Force chains and contact network topology in sheared packings of elongated particles. Phys Rev E Stat Soft Matter Phys 85:031303

Baudet B, Zhang X (2013) Particle breakage in gap-graded soil. Géotech Lett 3:72–77

Beakawi Al-Hashemi HM, Baghabra Al-Amoudi OS (2018) A review on the angle of repose of granular materials. Powder Technol 330:397–417

Ben-Nun O, Einav I (2010) The role of self-organization during confined comminution of granular materials. Philos Trans R Soc A Math Phys Eng Sci 368:231–247

Ben-Nun O, Einav I, Tordesillas A (2010) Force attractor in confined comminution of granular materials. Phys Rev Lett 104:108001

Chen Q, Zhou CJ, Wang C, Zhou C (2021) Size effect on creep behaviour and creep model of slate rockfill with oversized particles. Proc Inst Civ Eng-Geotech Eng 1–12

Ciantia MO, Arroyo M, Calvetti F, Gens A (2015) An approach to enhance efficiency of dem modelling of soils with crushable grains. Geotechnique 65:91–110

Cil MB, Buscarnera G (2016) DEM assessment of scaling laws capturing the grain size dependence of yielding in granular soils. Granul Matter 18:1–15

Cil MB, Sohn C, Buscarnera G (2020) DEM modeling of grain size effect in brittle granular soils. J Eng Mech 146:04019138

Coetzee CJ (2017) Review: calibration of the discrete element method. Powder Technol 310:104–142

De Bono JP, McDowell GR (2014) DEM of triaxial tests on crushable sand. Granul Matter 16:551–562

de Bono JP, McDowell GR (2015) An insight into the yielding and normal compression of sand with irregularly-shaped particles using DEM. Powder Technol 271:270–277

Domenica C, Louis G (2022) Effects of parallel gradation on strength properties of ballast materials. Adv Meas Model Soil Behav 1–7

Duan K, Kwok CY, Ma X (2017) DEM simulations of sandstone under true triaxial compressive tests. Acta Geotech 12:495–510

Einav I (2007) Breakage mechanics-part I: theory. J Mech Phys Solids 55:1274–1297

Emanuele F (1969) Tests on cohesionless materials for rockfill dams. J Soil Mech Found Div 95:313–332

Frossard E, Hu W, Dano C, Hicher PY (2012) Rockfill shear strength evaluation: a rational method based on size effects. Geotechnique 62:415–427

Fu R, Hu X, Zhou B (2017) Discrete element modeling of crushable sands considering realistic particle shape effect. Comput Geotech 91:179–191

Gamboa CJN (2011) Mechanical behavior of rockfill materials: application to concrete face rockfill dams. Doctoral dissertation, École Centrale Paris

Gao LS, Cai CG, Zhu JQ (2006) An analysis method for uncoupled K-G model parameters in site confined compression test of rock-fill materials and its application on CFRD. J Hydroelectr Eng 25:26–33

Guo WL, Zhu JG, Wen YF (2016) Unified description for four grading scale methods for coarse aggregate. Chin J Geotech Eng 38:1473–1480

Gupta AK (2016) Effects of particle size and confining pressure on breakage factor of rockfill materials using medium triaxial test. J Rock Mech Geotech Eng 8:378–388

He JZ, Liu F, Deng G, Fu PC (2021) Relationships between gradation and deformation behavior of dense granular materials: Role of high-order gradation characteristics. Int J Numer Anal Methods Geomech 45:1791–1808

Hu W, Dano C, Hicher PY, Le Touzo JY, Derkx F, Merliot E (2011) Effect of sample size on the behavior of granular materials. Geotech Test J 34:1–12

Huang X, Hanley KJ, O’Sullivan C, Kwok FCY (2014) Effect of sample size on the response of DEM samples with a realistic grading. Particuology 15:107–115

Huang QS, Zhou W, Ma G, Ng TT, Xu K (2020) Experimental and numerical investigation of Weibullian behavior of grain crushing strength. Geosci Front 11:401–411

Jia YF, Xu B, Chi SC, Xiang B, Zhou Y (2017) Research on the particle breakage of rockfill materials during triaxial tests. Int J Geomech 17:04017085

Jiang MD, Yang ZX, Barreto D, Xie YH (2018) The influence of particle-size distribution on critical state behavior of spherical and non-spherical particle assemblies. Granul Matter 20:1–15

Karatza Z, Andò E, Papanicolopulos SA, Viggiani G, Ooi JY (2019) Effect of particle morphology and contacts on particle breakage in a granular assembly studied using X-ray tomography. Granul Matter 21:1–13

Kong XJ, Liu JM, Zou DG (2016) Scale effect of rockfill and multiple-scale triaxial test platform. Chin J Geotech Eng 38:1941–1947

Kong XJ, Ning FW, Liu JM, Zou DG, Zhou CG (2019) Scale effect of rockfill materials using super-large triaxial tests. Chin J Geotech Eng 41:255–261

Kuang DM, Long ZL, Ogwu I, Chen Z (2021) A discrete element method (DEM)-based approach to simulating particle breakage. Acta Geotech 1–14

Kuhn MR, Bagi K (2009) Specimen size effect in discrete element simulations of granular assemblies. J Eng Mech 135:485–492

Latham JP, Munjiza A, Garcia X, Xiang JS, Guises R (2008) Three-dimensional particle shape acquisition and use of shape library for DEM and FEM/DEM simulation. Miner Eng 21:797–805

Li C, He CR, Wang C, Zhao HF (2008) Study of scale effect of large-scale triaxial test of coarse-grained materials. Rock Soil Mech 29:563–566

Li SY, Wang TC, Wang H, Jiang MJ, Zhu JG (2022) Experimental studies of scale effect on the shear strength of coarse-grained soil. Appl Sci 12:1–16

Linero-Molina S, Azéma E, Estrada N, Fityus S, Simmons J, Lizcano A (2021) Impact of sample scaling on shear strength: coupled effects of grains size and shape. EPJ Web Conf 249:06011

Liu MC, Gao YF, Liu HL (2011) Effect of particle breakage on strength and deformation of modeled rockfills. Chin J Geotech Eng 33:1691–1699

Luo XF, Zhao L, Dong H (2021) Study on DEM parameter calibration and wear characteristics of vanadium-titanium magnetite pellets. Powder Technol 393:427–440

Ma G, Chang XL, Zhou W, Ng TT (2014) Mechanical response of rockfills in a simulated true triaxial test: a combined FDEM study. Geomech Eng 7:317–333

Ma G, Zhou W, Chang XL (2014) Modeling the particle breakage of rockfill materials with the cohesive crack model. Comput Geotech 61:132–143

Ma G, Zhou W, Chang XL, Chen MX (2016) A hybrid approach for modeling of breakable granular materials using combined finite-discrete element method. Granul Matter 18:1–17

Ma G, Zhou W, Regueiro RA, Wang Q, Chang XL (2017) Modeling the fragmentation of rock grains using computed tomography and combined FDEM. Powder Technol 308:388–397

Marachi N (1969) Strength and deformation characteristics of rockfills material. University of California, Berkeley

Marachi ND, Chan CKSHB (1972) Evaluation of properties of rockfill materials. J Soil Mech Found Div 98:95–114

Marsal RJ (1967) Large scale testing of rockfill materials. J Soil Mech Found Div 93:27–43

McDowell GR, de Bono JP (2013) On the micro mechanics of one-dimensional normal compression. Geotechnique 63:895–908

Ministry of Housing and Urban-Rural Development of the People's Republic of China. GB/T 50123–2019 Standard for geotechnical testing method. China Planning Press, 2019

Nguyen DH, Azéma E, Sornay P, Radjai F (2015) Effects of shape and size polydispersity on strength properties of granular materials. Phys Rev E 91:032203

Ning FW, Kong XJ, Zou DG, Liu JM, Yu X, Zhou CG (2021) Scale effect of rockfill materials and its influences on deformation and stress analysis of Aertashi CFRD. Chin J Geotech Eng 43:263–270

Ouadfel H, Rothenburg L (2001) ‘Stress-force-fabric’ relationship for assemblies of ellipsoids. Mech Mater 33:201–221

Ovalle C, Dano C (2020) Effects of particle size–strength and size–shape correlations on parallel grading scaling. Géotech Lett 10:191–197

Ovalle C, Frossard E, Dano C, Hu W, Maiolino S, Hicher PY (2014) The effect of size on the strength of coarse rock aggregates and large rockfill samples through experimental data. Acta Mech 225:2199–2216

Qu TM, Wang M, Feng YT (2022) Applicability of discrete element method with spherical and clumped particles for constitutive study of granular materials. J Rock Mech Geotech Eng 14:240–251

Radjai F, Jean M, Moreau J et al (2016) Force distributions in dense two-dimensional granular systems. Phys Rev Lett 77:274

Rahmani H, Panah AK (2021) Influence of particle size on particle breakage and shear strength of weak rockfill. Bull Eng Geol Environ 80:473–489

Shao XQ, Chi SC, Tao Y, Zhou XX (2020) DEM simulation of the size effect on the wetting deformation of rockfill materials based on single-particle crushing tests. Comput Geotech 123:103429

Sitharam TG, Nimbkar MS (2000) Micromechanical modelling of granular materials: Effect of particle size and gradation. Geotech Geol Eng 18:91–117

Thornton C, Antony SJ (1998) Quasi-static deformation of participate media. Philos Trans R Soc A Math Phys Eng Sci 356:2763–2782

Tsoungui O, Vallet D, Charmet JC (1999) Numerical model of crushing of grains inside two-dimensional granular materials. Powder Technol 105:190–198

Varadarajan A, Sharma KG, Venkatachalam K, Gupta AK (2003) Testing and modeling two rockfill materials. J Geotech Geoenviron Eng 129:206–218

Voivret C, Radjaï F, Delenne JY, El Youssoufi MS (2009) Multiscale force networks in highly polydisperse granular media. Phys Rev Lett 102:2–5

Wang CH, Cheng YP, He XX, Yi MH, Wang ZY (2019) Size effect on uniaxial compressive strength of single coal particle under different failure conditions. Powder Technol 345:169–181

Wang JW, Chi SC, Shao XQ, Zhou XX (2021) Determination of the mechanical parameters of the microstructure of rockfill materials in triaxial compression DEM simulation. Comput Geotech 137:104265

Wang H, Cui YJ, Zhang F, Liu JJ (2022) Effect of grain breakage on the compressibility of soils. Acta Geotech 17:769–778

Wang J, Gutierrez M (2010) Discrete element simulations of direct shear specimen scale effects. Geotechnique 60:395–409

Wang Y, Ma G, Mei J, Zou YX, Zhang D, Zhou W (2021) Machine learning reveals the influences of grain morphology on grain crushing strength. Acta Geotech 16:3617–3630

Wang P, Yin ZY, Wang ZY (2022) Micromechanical investigation of particle-size effect of granular materials in biaxial test with the role of particle breakage. J Eng Mech 148:1–14

Wang SR, Zhu JG, Chen HF, Weng HY (2019) Study on strength and deformation characteristics of coarse aggregate after different grading scale methods. J Hebei Univ Eng 1:36–41

Wei KM, Zhu S, Yu XH (2014) Influence of the scale effect on the mechanical parameters of coarse-grained soils. Iran J Sci Technol Trans Civ Eng 38:75–84

Wensrich CM, Katterfeld A (2012) Rolling friction as a technique for modelling particle shape in DEM. Powder Technol 217:409–417

Wiącek J, Molenda M (2014) Effect of particle size distribution on micro-and macromechanical response of granular packings under compression. Int J Solids Struct 51:4189–4195

Wiącek J, Molenda M (2016) Representative elementary volume analysis of polydisperse granular packings using discrete element method. Particuology 27:88–94

Wl GUO (2018) Study on the particle breakage evolution and constitutive model of coarse-grained soils. Hohai University, Nanjing ((in Chinese))

Wu W, Ma G, Zhou W, Wang D, Chang XL (2019) Force transmission and anisotropic characteristics of sheared granular materials with rolling resistance. Granul Matter 21:1–18

Wu LQ, Ye F, Lin WQ (2020) Experimental study on scale effect of mechanical properties of rockfill materials. Chin J Geotech Eng 42:141–145

Wu LQ, Zhu S, Zhang XH, Chen WL (2016) Analysis of scale effect of coarse-grained materials. Rock Soil Mech 37:2187–2197

Xiao Y, Liu HL, Chen YM, Jiang JS (2014) Strength and deformation of rockfill material based on large-scale triaxial compression tests. II. Influence of particle breakage. J Geotech Geoenviron Eng 140:1–10

Xiao Y, Meng MQ, Daouadji A, Chen QS, Wu ZJ, Jiang X (2020) Effects of particle size on crushing and deformation behaviors of rockfill materials. Geosci Front 11:375–388

Xu K, Zhou W, Ma G, Chang XL, Yang LF (2018) Review of particle breakage simulation based on DEM. Chin J Geotech Eng 40:880–889

Yang G, Jiang Y, Nimbalkar S, Sun YF, Li NH (2019) Influence of particle size distribution on the critical state of rockfill. Adv Civ Eng 2019:1–7

Ye Y, Zeng YW, Sun HQ, Liu Y, Chen X, Ma WJ (2021) An experimental study on the influence of multiple contacts and size on contact behavior of marble sphere. Granul Matter 23:1–13

Yu FW (2017) Characteristics of particle breakage of sand in triaxial shear. Powder Technol 320:656–667

Zhao SW, Evans TM, Zhou XW (2018) Shear-induced anisotropy of granular materials with rolling resistance and particle shape effects. Int J Solids Struct 150:268–281

Zhao JD, Guo N (2014) Rotational resistance and shear-induced anisotropy in granular media. Acta Mech Solida Sin 27:1–14

Zhou LL, Chu XH, Xu YJ (2017) Breakage behavior of sand under true triaxial stress based on discrete element method. Chin J Geotech Eng 39:839–847

Zhou W, Hua JJ, Chang XL, Zhou CB (2011) Settlement analysis of the Shuibuya concrete-face rockfill dam. Comput Geotech 38:269–280

Zhou W, Liu JY, Ma G, Chang XL (2017) Three-dimensional DEM investigation of critical state and dilatancy behaviors of granular materials. Acta Geotech 12:527–540

Zhou W, Ma G, Chang X-L, Duan Y (2015) Discrete modeling of rockfill materials considering the irregular shaped particles and their crushability. Eng Comput 32:1104–1120

Zhou W, Ma G, Chang XL, Zhou CB (2013) Influence of particle shape on behavior of rockfill using a three-dimensional deformable DEM. J Eng Mech 139:1868–1873

Zhou X, Ma G, Zhang Y (2019) Grain size and time effect on the deformation of rockfill dams: a case study on the shuibuya CFRD. Geotechnique 69:606–619

Zhou W, Wang D, Ma G, Cao XX, Hu C, Wu W (2020) Discrete element modeling of particle breakage considering different fragment replacement modes. Powder Technol 360:312–323

Zhou W, Xu K, Ma G, Chang XL (2019) On the breakage function for constructing the fragment replacement modes. Particuology 44:207–217

Zhou W, Yang LF, Ma G, Chang XL, Cheng YG, Li DQ (2015) Macro–micro responses of crushable granular materials in simulated true triaxial tests. Granul Matter 17:497–509

Zhou W, Yang LF, Ma G, Chang XL, Lai ZQ (2016) DEM analysis of the size effects on the behavior of crushable granular materials. Granul Matter 18:1–11

Zhu S, Wang J, Zhong CX, Wu LQ (2019) Experimental study on scale effect of the dry density of rockfill material. Chin J Rock Mech Eng 38:1073–1080

Acknowledgements

The authors gratefully acknowledge financial support by the National Natural Science Foundation of China (Grant Nos. 51825905, U1865204). The numerical calculations in this paper have been done on the supercomputing system in the Supercomputing Center of Wuhan University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

An, N., Ma, G., Zhou, H. et al. DEM investigation of the microscopic mechanism of scale effect of sandy gravel material. Acta Geotech. 18, 1373–1390 (2023). https://doi.org/10.1007/s11440-022-01667-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-022-01667-6