Abstract

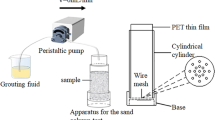

The use of the calcareous soil as a backfill material in ocean constructions faces pervasive challenges due to the significant rate of particle fracture. To meet the requirements of marine ecological protection, a bio-cementing technique, microbially induced carbonate precipitation (MICP), has emerged as a green method for improving the soil properties of calcareous sands. This paper presents a detailed study on the effect of MICP on the fracture behaviours of calcareous particles and its treating mechanism at microscopic scale level. First, individual calcareous and dolomite particles were treated by MICP for different numbers of rounds. The increase ratio of the particle mass and the filling degree of the intra-particle pores were then measured to evaluate the treatment effect of MICP on individual sand particles. Combining with scanning electron microscopy measurements of the evolution of the particle morphology and internal microstructures of the calcareous particles, the intra-particle pore filling effect as well as the surface coating effect induced by MICP treatment were directly observed. Finally, a series of single-particle crushing tests indicated that the intra-particle pore filling effect of MICP rather than the surface coating effect played the dominant role in improving the fracture pattern and fracture strength of calcareous sand particles.

Similar content being viewed by others

References

Al QA, Soga K (2013) Effect of chemical treatment used in MICP on engineering properties of cemented soils. Géotechnique 63:331–339

API (American Petroleum Institute) (2000). Recommended practice for planning, designing, and constructing fixed offshore platforms-working stress design. API Publishing Services, Washington, D.C.

Brandes H (2011) Simple shear behaviour of calcareous and quartz sands. Geotech Geolog Eng 29:113–126

Cheng L, Shahin MA, Cord-Ruwisch R (2014) Bio-cementation of sandy soil using microbially induced carbonate precipitation for marine environments. Géotechnique 64:1010–1013

Coop MR (1990) The mechanics of uncemented carbonate sands. Géotechnique 40:607–626

Coop MR, Sorensen KK, Bodas Freitas T, Georgoutsos G (2004) Particle breakage during shearing of a carbonate sand. Géotechnique 54:157–163

Cui MJ, Zheng JJ, Zhang RJ, Lai HJ, Zhang J (2017) Influence of cementation level on the strength behaviour of bio-cemented sand. Acta Geotech 12:971–986

Cui MJ, Zheng JJ, Chu J, Wu CC, Lai HJ (2021) Bio-mediated calcium carbonate precipitation and its effect on the shear behaviour of calcareous sand. Acta Geotech 16:1377–1389

DeJong JT, Soga K, Kavazanjian E et al (2013) Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Géotechnique 63:287–301

Dyer M, Viganotti M (2016) Oligotrophic and eutrophic MICP treatment for silica and carbonate sands. Bioinspir Biomin Nan 6:168–183

Fu R, Hu X, Zhou B (2017) Discrete element modeling of crushable sands considering realistic particle shape effect. Comput Geotech 91:179–191

Han Z, Cheng X, Ma Q (2016) An experimental study on dynamic response for MICP strengthening liquefiable sands. Earthq Eng Eng Vib 15:673–679

He J, Chu J, Gao Y et al (2019) Research advances and challenges in biogeotechnologies. Geotech Res 6:144–155

Hu G, Zhou B, Fu R, Guo Y, Han C, Lv K (2021) Discrete element modeling of the compression molding of polymer–crystal composite particles. Powder Technol 390:112–125

Jardine R, Chow F, Overy R, Standing J (2005) ICP design methods for driven piles in sands and clays. Thomas Telford

Klotz E, Coop M (2001) An investigation of the effect of soil state on the capacity of driven piles in sands. Géotechnique 51:733–751

Lai Y, Yu J, Liu S, Liu J, Wang R, Dong B (2021) Experimental study to improve the mechanical properties of iron tailings sand by using MICP at low pH. Constr Build Mater 273:21729

Liu L, Liu H, Xiao Y, Chu J, Xiao P, Wang Y (2018) Biocementation of calcareous sand using soluble calcium derived from calcareous sand. Bull Eng Geol Environ 77:1781–1791

Liu L, Liu H, Stuedlein AW, Evans TM, Xiao Y (2019) Strength, stiffness, and microstructure characteristics of biocemented calcareous sand. Can Geotech J 56:1502–1513

Liu B, Zhu C, Tang CS, Xie YH, Yin LY, Cheng Q, Shi B (2020) Bio-remediation of desiccation cracking in clayey soils through microbially induced calcite precipitation (MICP). Eng Geol 264:105389

Liu KW, Jiang NJ, Qin JD, Wang YJ, Tang CS, Han XL (2021) An experimental study of mitigating coastal sand dune erosion by microbial-and enzymatic-induced carbonate precipitation. Acta Geotech 16:467–480

Lv C, Zhu C, Tang CS, Cheng Q, Yin LY, Shi B (2021) Effect of fiber reinforcement on the mechanical behavior of bio-cemented sand. Geosynth Int 28:195–205

Miao G, Airey D (2013) Breakage and ultimate states for a carbonate sand. Géotechnique 63:1221–1229

Minto JM, Lunn RJ, El Mountassir G (2019) Development of a reactive transport model for field-scale simulation of microbially induced carbonate precipitation. Water Resour Res 55:7229–7245

Montaggioni LF, Braithwaite CJR (2009) Chapter Eight Reef Diagenesis. Dev Mar Geol 5:323–372

Montoya BM, DeJong JT, Boulanger RW (2013) Dynamic response of liquefiable sand improved by microbial induced calcite precipitation. Géotechnique 63:302–312

Montoya BM, DeJong JT (2015) Stress-strain behavior of sands cemented by microbially induced calcite precipitation. J Geotech Geoenviron Eng 141:04015019

Mujah D, Shahin MA, Cheng L (2017) State-of-the-art review of biocementation by microbially induced calcite precipitation (MICP) for soil stabilization. Geomicrobiol J 34:524–537

Nakata AFL, Hyde M, Hyodo H, Murata (1999) A probabilistic approach to sand particle crushing in the triaxial test. Géotechnique 49:567–583

Nassar MK, Gurung D, Bastani M et al (2018) Large-scale experiments in microbially induced calcite precipitation (MICP): Reactive transport model development and prediction. Water Resour Res 54:480–500

van Paassen LA, Ghose R, van der Linden TJ, van der Star WR, van Loosdrecht MC (2010) Quantifying biomediated ground improvement by ureolysis: large-scale biogrout experiment. J Geotech Geoenviron Eng 136:1721–1728

Rong H, Qian CX, Li L (2012) Study on microstructure and properties of sandstone cemented by microbe cement. Constr Build Mater 36:687–694

Shahnazari H, Jafarian Y, Tutunchian MA, Rezvani R (2016) Probabilistic assessment of liquefaction occurrence in calcareous fill materials of Kawaihae Harbor. Hawaii Int J Geomech 16:05016001

Shen J, Dongsheng XU, Liu Z, Wei H (2020) Effect of particle characteristics stress on the mechanical properties of cement mortar with coral sand. Constr Build Mater 260:

Terzis D, Bernier-Latmani R, Laloui L (2016) Fabric characteristics and mechanical response of bio-improved sand to various treatment conditions. Geotech Lett 6:50–57

Terzis D, Laloui L (2018) 3-D micro-architecture and mechanical response of soil cemented via microbial-induced calcite precipitation. Sci Rep 8:1–11

Terzis D, Laloui L (2019) A decade of progress and turning points in the understanding of bio-improved soils: A review. J Geotech Geoenviron Eng 19:100116

Wang XZ, Jiao YY, Wang R, Hu MJ, Meng QS, Tan FY (2011) Engineering characteristics of the calcareous sand in Nansha Islands, South China Sea. Eng Geol 120:40–47

Wang Y, Soga K, DeJong JT, Kabla AJ (2021) Effects of bacterial density on growth rate and characteristics of microbial-induced CaCO3 precipitates: Particle-scale experimental study. J Geotech Geoenviron Eng 147:04021036

Wang W, Coop MR (2016) An investigation of breakage behaviour of single sand particles using a high-speed microscope camera. Géotechnique 66:984–998

Wei H, Zhao T, Meng Q, Wang X, He J (2018) Experimental evaluation of the shear behavior of fiber-reinforced calcareous sands. Int J Geomech 18:04018175

Van Wijngaarden WK, Vermolen FJ, Van Meurs GAM, Vuik C (2011) Modelling biogrout: a new ground improvement method based on microbial-induced carbonate precipitation. Transp Porous Media 87:397–420

Xiao Y, Liu H, Chen Q, Ma Q, Xiang Y, Zheng Y (2017) Particle breakage and deformation of carbonate sands with wide range of densities during compression loading process. Acta Geotech 12:1177–1184

Xiao P, Liu H, Xiao Y, Stuedlein AW, Evans TM (2018) Liquefaction resistance of bio-cemented calcareous sand. Soil Dyn Earthq Eng 107:9–19

Xiao Y, Stuedlein AW, Chen Q, Liu H, Liu P (2018) Stress-strain-strength response and ductility of gravels improved by polyurethane foam adhesive. J Geotech Geoenviron Eng 144:04017108

Xiao Y, Yuan Z, Chu J et al (2019) Particle breakage and energy dissipation of carbonate sands under quasi-static and dynamic compression. Acta Geotech 14:1741–1755

Xiao Y, Chen H, Stuedlein AW et al (2020) Restraint of particle breakage by biotreatment method. J Geotech Geoenviron Eng 146:04020123

Zhang X, Chen Y, Liu H, Zhang Z, Ding X (2020) Performance evaluation of a MICP-treated calcareous sandy foundation using shake table tests. Soil Dyn Earthq Eng 129:105959

Zhao B, Wang J, Coop MR, Viggiani G, Jiang M (2015) An investigation of single sand particle fracture using X-ray micro-tomography. Géotechnique 65:625–641

Zhou B, Ku Q, Wang H, Wang J (2020) Particle classification and intra-particle pore structure of carbonate sands. Eng Geol 279:105889

Acknowledgements

This study was supported by Research Grants 41877233, 42072298 and 41931286 from the National Natural Science Foundation of China and a General Research Fund Grant (No. CityU 11207321) from the Research Grants Council of the Hong Kong SAR.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Calculation of convex hull’s volume

Appendix: Calculation of convex hull’s volume

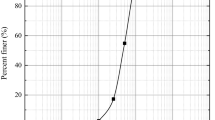

A convex hull is defined as the minimal region containing all line segments consisting of any two points inside. An intrinsic function in Python3.8 was used to generate the convex hull, and calculate its volume Vcon of a given particle, as illustrated in Fig. 4. An oriented bounding box (OBB) was obtained based on a principal component analysis (PCA) of all the voxels belonging to the particle volume. The dimensions of the particle a, b and c are the length, width and height of OBB. Figure 15 demonstrates the original morphology and convex hull of 30 calcareous particles. Figure 16 shows the correlation between the convex hull’s volume (Vcon) and the bound box’s volume (Vbox) for all the particles. A well linear relationship with a slope of 0.3 was identified between these two parameters. In practical experiments, a vernier caliper was used to measure the dimensions a, b and c of the tested particle, and a uniform empirical equation Vcon = 0.3abc was adopted to approximately calculate its convex hull’s volume.

Rights and permissions

About this article

Cite this article

Zhou, B., Zhang, X., Wang, J. et al. Insight into the mechanism of microbially induced carbonate precipitation treatment of bio-improved calcareous sand particles. Acta Geotech. 18, 985–999 (2023). https://doi.org/10.1007/s11440-022-01625-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-022-01625-2