Abstract

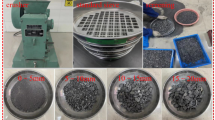

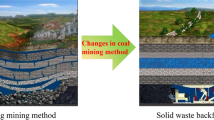

Filling of gangue formed in coal mining is an effective means to realize green mining in coal mine. The key of gangue filling mining is to accurately understand the breaking mechanism and pore evolution of gangue under load. Therefore, in this paper, firstly, the yield criterion of granular materials based on radius of curvature and contact stress is built, which concluded that the change of grain size during the process of gangue compression is the main factor affecting the crushing characteristics of gangue. Secondly, the numerical simulation method which can simulate the loading of gangue is put forward, and realize the re-crushing of gangue under compression and the influence of particle shape on the compression and crushing of gangue. Finally, the calculation method of breaking rate based on single particle is given, and the influence of the location of gangue particle on the breaking rate of rock sample is analyzed.

Similar content being viewed by others

References

Ai J, Chen JF, Rotter JM, Ooi JY (2011) Assessment of rolling resistance models in discrete element simulations. Powder Technol 206(3):269–282

Cavarretta I, O’Sullivan C, Coop MR (2017) The relevance of roundness to the crushing strength of granular materials. Geotechnique 67(4):301–312

Chen M, Wen P, Wang C, Chai Z, Gao Z (2020) Evaluation of particle size distribution and mechanical properties of mineral waste slag as filling material. Constr Build Mater 253:119183

Donohue S, O’Sullivan C, Long M (2009) Particle breakage during cyclic triaxial loading of a carbonate sand. Géotechnique 59:477–482

Einav I (2007) Breakage mechanics—part I: theory. J Mech Phys Solids 55(6):1274–1297

Guo Y, Yan K, Cui L, Cheng F, Lou HH (2014) Effect of Na2CO3 additive on the activation of coal gangue for alumina extraction. Int J Miner Process. 131:51–57

Gupta VK (2017) Effect of size distribution of the particulate material on the specifific breakage rate of particles in dry ball milling. Powder Technol 305:714–722

Hardin BO, Blandford GE (1989) Elasticity of particulate materials. J Geotech Eng 115(6):788–805

Huang Y, Li J, Ma D, Gao H, Ouyang S (2019) Triaxial compression behaviour of gangue solid wastes under effects of particle size and confining pressure. Sci Total Environ 693:133607

Huang Y, Li J, Song T, Kong G, Li M (2017) Analysis on fifilling ratio and shield supporting pressure for overburden movement control in coal mining with compacted backfifilling. Energies 10:311

Huang Y, Zhang J, Zhang Q, Nie S (2011) Backfilling technology of substituting waste and fly ash for coal underground in china coal mining area. Environ Eng Manag J 10(6):769–775

Jiang MJ, Yu HS, Harris D (2005) A novel discrete model for granular material incorporating rolling resistance. Comp Geotech 32(5):340–357

Li J, Huang Y, Chen Z, Li M, Qiao M, Kizil M (2018) Particle-crushing characteristics and acoustic-emission patterns of breaking gangue backfifilling material under cyclic loading. Minerals 8:2446

Li B, Liang Y, Zhang L, Zou Q (2019) Breakage law and fractal characteristics of broken coal and rock masses with different mixing ratios during compaction. Energy Sci Eng. 7(3):1000–1015

Li B, Yan H, Zhang J, Zhou N (2020) Compaction property prediction of mixed gangue backfill materials using hybrid intelligence models: a new approach. Constr Build Mater 247:118633

Li M, Zhang J, Huang Y, Zhou N (2017) Effects of particle size of crushed gangue backfill materials on surface subsidence and its application under buildings. Environ Earth Sci 76(17):603

Liu L, Yao Y, Luo T, Zhou A (2020) A constitutive model for granular materials subjected to a large stress range. Comput Geotech 120:103408

Ma D, Duan H, Liu J, Li X, Zhou Z (2019) The role of gangue on the mitigation of mining-induced hazards and environmental pollution: an experimental investigation. Sci Total Environ 664:436–448

Nakata Y, Hyodo M, Hyde AF, Kato Y, Murata H (2001) Microscopic particle crushing of sand subjected to high pressure one-dimensional compression. Soils and Found 41(1):69–82

Rozenblat Y, Portnikov D, Levy A, Kalman H, Aman S, Tomas J (2011) Strength distribution of particles under compression. Powder Technol 208:215–224

Shao XQ, Chi SC, Tao Y, Zhou XX (2020) DEM simulation of the size effect on the wetting deformation of rockfill materials based on single-particle crushing tests. Comp Geotech 123:103429

Suescun-Florez E, Iskander M, Bless S (2020) Evolution of particle damage of sand during axial compression via arrested tests. Acta Geotech 15(1):95–112

Sun Q, Zhang J, Zhou N (2018) Study and discussion of short-strip coal pillar recovery with cemented paste backfifill. Int J Rock Mech Min Sci 104:147–155

Xu JM, Zhang JX, Huang YL, Ju F (2011) Experimental research on the compress deformation characteristic of waste-fly ash and its application in backfilling fully mechanized coal mining technology. J Min Saf Eng 28(1):158–162

Zhang JX, Huang YL, Li M, Zhang Q, Liu Z (2014) Test on mechanical properties of solid backfill materials. Mater Res Innov 18(sup2):S2-960

Zhang J, Li M, Liu Z, Zhou N (2017) Fractal characteristics of crushed particles of coal gangue under compaction. Powder Technol 305:12–18

Zhang Y, Ling TC (2020) Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials – A review. Constr Build Mater 234:117424

Zhang C, Liu J, Zhao Y, Han P, Zhang L (2020) Numerical simulation of broken coal strength influence on compaction characteristics in goaf. Nat Resour Res 29(4):1–17

Zhang C, Ren Z, Hao D, Zhang T (2020) Numerical simulation of particle size influence on the breakage mechanism of broken coal. Arab J Sci Eng 45(11):9171–9185

Zhang C, Tu S, Zhang L (2017) Analysis of broken coal permeability evolution under cyclic loading and unloading conditions by the model based on the hertz contact deformation principle. Transp Porous Media 119(3):739–754

Zhang C, Tu S, Zhao Y (2019) Compaction characteristics of the caving zone in a longwall goaf: a review. Environm Earth Sci 78(1):27

Zhang C, Zhang L (2019) Permeability characteristics of broken coal and rock under cyclic loading and unloading. Nat Resour Res 28(3):1055–1069

Zhang J, Zhang Q, Spearing AS, Miao X, Guo S, Sun Q (2017) Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int J Min Sci Technol 27(1):17–27

Zhang C, Zhao Y and Bai, Q (2022) 3D DEM method for compaction and breakage characteristics simulation of broken rock mass in goaf. Acta Geotechnica, 1–17

Zhou N, Han X, Zhang J, Li M (2016) Compressive deformation and energy dissipation of crushed coal gangue. Powder Technol 297:220–228

Acknowledgments

This work was supported by the Natural Science Foundation of Beijing (8212032), the National Natural Science Foundation of China (U1910206, 52104155), China Postdoctoral Science Foundation (2020M682563), Scientific Research Foundation of Hunan Provincial Education Department (19C0743), and the Scientific Research Foundation for Doctor of Hunan University of Science and Technology (E52052).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cun, Z., Bo, L., Ziyu, S. et al. Breakage mechanism and pore evolution characteristics of gangue materials under compression. Acta Geotech. 17, 4823–4835 (2022). https://doi.org/10.1007/s11440-022-01599-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-022-01599-1