Abstract

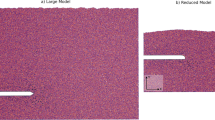

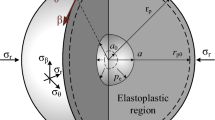

The Atlantic razor clam exhibits exceptional penetration performance in wet sands by periodically expanding and contracting its shell and foot during burrowing. Essentially, this periodic penetration movement can be simplified as a cyclic alternation of cylinder expansion and cone penetration, which are analogous to the geotechnical pressuremeter test and the cone penetration test. The dynamic penetration movement of the razor clam was simplified as four major connective steps—cylinder expansion, cone penetration, cylinder contraction, and cylinder retraction—and the kinematics was parameterized based on the biological data. Using a simplified and idealized synthetic dry sand sample, we attempted to model the clam-inspired penetration process using two common geomechanics tools, an analytical model based on cavity expansion theory and a numerical discrete element method (DEM), and to showcase the advantages and limitations of these two approaches in the dynamic penetration modeling. In the analytical model, the four consecutive steps were assumed to be independent. The penetration resistance and energy consumption for each step were therefore roughly estimated using cavity expansion theory; in parallel, the independent cylinder expansion and cone penetration process as well as the clam-inspired coupled dynamic penetration process were also modeled using the DEM method. When the results were compared, it was found that the adopted cavity expansion theory solutions can predict the independent cylinder expansion and cone penetration behaviors, given that the parameters were carefully chosen and calibrated. However, it cannot capture the interference effect in a coupled dynamic penetration process. Specifically, the analytical model overestimates the cone penetration resistance of the coupled dynamic penetration process; the cylindrical shaft expansion causes stress release around the cone, leading to a reduction in the tip resistance as the cone continues to penetrate. The analytical model also underestimates the expansion pressure in the dynamic penetration process, which is attributed to the change in stress and fabric state caused by the cyclic expansion/contraction movement. Moreover, the clam-inspired dynamic penetration was found to reduce the energetic cost on the penetration of cone and shaft for about 36% and still maintain a slightly lower energy consumption with additional cost on the cyclic shaft expansion, compared with the pure cone penetration strategy. With a better future understanding of the highly effective and efficient self-burrowing behavior of natural burrowers, it is envisioned to develop self-burrowing robots for a spectrum of geotechnical applications.

Modified from Trueman [53]

Similar content being viewed by others

References

Abdalla A, Hettiaratchi D, Reece A (1969) The mechanics of root growth in granular media. J Agric Eng Res 14(3):236–248

Abedi S, Rechenmacher AL, Orlando AD (2012) Vortex formation and dissolution in sheared sands. Granul Matter 14(6):695–705

Ajalloeian R, Yu H (1998) Chamber studies of the effects of pressure meter geometry on test results in sand. Geotechnique 48(5):621–636

Arroyo M, Butlanska J, Gens A, Calvetti F, Jamiolkowski M (2011) Cone penetration tests in a virtual calibration chamber. Geotechnique 61(6):525–531

ASTMD3441-16, (2016) Standard test method for mechanical cone penetration testing of soils. ASTM International, West Conshohocken

ASTMD4719-07 (2016) Standard test method for prebored pressuremeter testing in soils. ASTM International, West Conshohocken

Backman ME, Goldsmith W (1978) The mechanics of penetration of projectiles into targets. Int J Eng Sci 16(1):1–99

Bienen B, Gaudin C, Cassidy M, Rausch L, Purwana O, Krisdani H (2012) Numerical modelling of a hybrid skirted foundation under combined loading. Comput Geotech 45:127–139. https://doi.org/10.1016/j.compgeo.2012.05.009

Bivin YK, Simonov I (2010) Mechanics of dynamic penetration into soil medium. Mech Solids 45(6):892–920

Bolton M, Gui M (1993) The study of relative density and boundary effects for cone penetration tests in centrifuge. University of Cambridge, Department of Engineering, Cambridge

Bolton MD, Gui M-W, Garnier J, Corte JF, Bagge G, Laue J, Renzi R (1999) Centrifuge cone penetration tests in sand. Géotechnique 49(4):543–552

Butlanska J (2014) Cone penetration test in a virtual calibration chamber

Butlanska J, Arroyo M, Gens A (2010) Size effects on a virtual calibration chamber. In: Benz T, Nordal S (eds) Numerical methods in geotechnical engineering. CRC Press, Balkema, pp 225–230

Butlanska J, Arroyo M, Gens A, O’Sullivan C (2013) Multi-scale analysis of cone penetration test (CPT) in a virtual calibration chamber. Can Geotech J 51(1):51–66

Cundall P (1988) Computer simulations of dense sphere assemblies. Micromech Granul Mater 4:113–123

Cundall PA, Strack OD (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

Das BM (2010) Principles of geotechnical engineering, 7th edn. Cengage Learning, Boston

Ding Y, Sharpe SS, Masse A, Goldman DI (2012) Mechanics of undulatory swimming in a frictional fluid. PLoS Comput Biol 8(12):e1002810

Dorgan KM (2015) The biomechanics of burrowing and boring. J Exp Biol 218(Pt 2):176–183

Elbaum R, Zaltzman L, Burgert I, Fratzl P (2007) The role of wheat awns in the seed dispersal unit. Science 316(5826):884–886

Fahey M (1986) Expansion of a thick cylinder of sand: a laboratory simulation of the pressuremeter test. Geotechnique 36(3):397–424

Falagush O, McDowell GR, Yu HS, de Bono JP (2015) Discrete element modelling and cavity expansion analysis of cone penetration testing. Granul Matter 17(4):483–495

Gazetas G, Makris N (1991) Dynamic pile-soil-pile interaction. Part I: analysis of axial vibration. Earthq Eng Struct Dyn 20(2):115–132

Gavin K, O’Kelly B (2007) Effect of friction fatigue on pile capacity in dense sand. J Geotech Geoenviron Eng 133(1):63–71

Geng Y, Yu H, McDowell G (2013) Discrete element modelling of cavity expansion and pressuremeter test. Geomech Geoeng 8(3):179–190

Germann D, Carbajal JP (2013) Burrowing behaviour of robotic bivalves with synthetic morphologies. Bioinspir Biomim 8(4):046009

Holland A, Dean J (1977) The biology of the stout razor clamTagelus plebeius: I. Animal-sediment relationships, feeding mechanism, and community biology. Chesap Sci 18(1):58–66

Holland P, Gordon J, Menna T, Charters A (1990) Hydrocode results for the penetration of continuous, segmented and hybrid rods compared with ballistic experiments. Int J Impact Eng 10(1–4):241–250

Hosoi AE, Goldman DI (2015) Beneath our feet: strategies for locomotion in granular media. In: Davis SH, Moin P (eds) Annual review of fluid mechanics, vol 47. Annual Reviews, Palo Alto, pp 431–453

Huang W, Sheng D, Sloan S, Yu H (2004) Finite element analysis of cone penetration in cohesionless soil. Comput Geotech 31(7):517–528

Isava M, Winter AG (2016) Razor clam-inspired burrowing in dry soil. Int J Non Linear Mech 81:30–39

Itasca Consulting Group I (2015) Guide book: theory and background PFC3D

Jardine R, Yang Z (2013) Measurement of stresses around closed-ended displacement piles in sand. Geotechnique. https://doi.org/10.1680/geot.9.P.137

Jung S, Winter AG, Hosoi A (2011) Dynamics of digging in wet soil. Int J Non Linear Mech 46(4):602–606

Lehane BM (1992) Experimental investigations of pile behavior using instrumented field piles. Ph.D. thesis, University of London Imperial College, London

Lin J, Wu W (2012) Numerical study of miniature penetrometer in granular material by discrete element method. Philos Mag 92(28–30):3474–3482

Lou M, Wang H, Chen X, Zhai Y (2011) Structure–soil–structure interaction: literature review. Soil Dyn Earthq Eng 31(12):1724–1731

Makris N, Gazetas G (1992) Dynamic pile–soil–pile interaction. Part II: lateral and seismic response. Earthq Eng Struct Dyn 21(2):145–162

Maladen RD, Ding Y, Umbanhowar PB, Goldman DI (2011) Undulatory swimming in sand: experimental and simulation studies of a robotic sandfish. Int J Robot Res 30(7):793–805

Maladen RD, Ding Y, Umbanhowar PB, Kamor A, Goldman DI (2011) Mechanical models of sandfish locomotion reveal principles of high performance subsurface sand-swimming. J R Soc Interface 8(62):1332–1345

Martinez A, DeJong JT, Jaeger RA, Khosravi A (2019) Evaluation of self-penetration potential of a bio-inspired site characterization probe by cavity expansion analysis. Can Geotech J. https://doi.org/10.1139/cgj-2018-0864

McDowell GR, Falagush O, Yu HS (2012) A particle refinement method for simulating DEM of cone penetration testing in granular materials. Geotech Lett 2:141–147

Mindlin RD, Deresiewica H (2013) Elastic spheres in contact under varying oblique forces. J Appl Mech 20:327–344

Omidvar M, Malioche JD, Bless S, Iskander M (2015) Phenomenology of rapid projectile penetration into granular soils. Int J Impact Eng 85:146–160

Potyondy D, Cundall P (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41(8):1329–1364

Ruiz S, Straub I, Schymanski SJ, Or D (2016) Experimental evaluation of earthworm and plant root soil penetration–cavity expansion models using cone penetrometer analogs. Vadose Zone J. https://doi.org/10.2136/vzj2015.09.0126

Salgado R (1993) Analysis of penetration resistance in sands. University of California, Berkeley

Salgado R, Mitchell J, Jamiolkowski M (1997) Cavity expansion and penetration resistance in sand. J Geotech Geoenviron Eng 123(4):344–354

Stewart J, Crouse C, Hutchinson TC, Lizundia B, Naeim F, Ostadan F (2012) Soil–structure interaction for building structures. NIST

Taboada A, Chang KJ, Radjaï F, Bouchette F (2005) Rheology, force transmission, and shear instabilities in frictional granular media from biaxial numerical tests using the contact dynamics method. J Geophys Res Solid Earth. https://doi.org/10.1029/2003JB002955

Terzaghi K, Peck RB, Mesri G (1996) Soil mechanics in engineering practice. Wiley, New York

Trueman E (1966) Observations on the burrowing of Arenicola marina (L.). J Exp Biol 44(1):93–118

Trueman E (1967) The dynamics of burrowing in Ensis (Bivalvia). Proc R Soc Lond B Biol Sci 166(1005):459–476

Trueman E, Brand A, Davis P (1966) The dynamics of burrowing of some common littoral bivalves. J Exp Biol 44(3):469–492

Vaid Y, Sasitharan S (1992) The strength and dilatancy of sand. Can Geotech J 29(3):522–526

Wallace H (1968) The dynamics of nematode movement. Annu Rev Phytopathol 6(1):91–114

White DJ, Bolton MD (2005) Comparing CPT and pile base resistance in sand. Proc Inst Civ Eng Geotech Eng 158(1):3–14

White DJ, Lehane BM (2004) Friction fatigue on displacement piles in sand. Geotechnique 54(10):645–658

Winter AG, Deits RL, Dorsch DS (2013) (Critical timescales for burrowing in undersea substrates via localized fluidization, demonstrated by RoboClam: a robot inspired by Atlantic razor clams. In Proceedings, ASME 2013 international design engineering technical conferences and computers and information in engineering conference. American Society of Mechanical Engineers, pp V06AT07A007–V006AT007A007

Winter AG, Deits RLH, Dorsch DS, Slocum AH, Hosoi AE (2014) Razor clam to RoboClam: burrowing drag reduction mechanisms and their robotic adaptation. Bioinspir Biomim 9(3):036009

Winter AG, Deits RLH, Hosoi AE (2012) Localized fluidization burrowing mechanics of Ensis directus. J Exp Biol 215(12):2072–2080

Winter AG, Hosoi A, Slocum AH, Deits RL (2009) The design and testing of RoboClam: a machine used to investigate and optimize razor clam-inspired burrowing mechanisms for engineering applications. In: Proceedings, ASME 2009 international design engineering technical conferences and computers and information in engineering conference. American Society of Mechanical Engineers, pp 721–726

Wu W, Ladjal S (2014) Scale effect of cone penetration in sand. In: 3rd International symposium on cone penetration testing, Las Vegas, Nevada, USA, pp 459–465

Yu H-S (2000) Cavity expansion methods in geomechanics. Springer, Berlin

Yu H-S (2006) The first James K. Mitchell lecture in situ soil testing: from mechanics to interpretation. Geomech Geoeng Int J 1(3):165–195

Yu H, Carter J (2002) Rigorous similarity solutions for cavity expansion in cohesive-frictional soils. Int J Geomech 2(2):233–258

Yu H, Mitchell J (1998) Analysis of cone resistance: review of methods. J Geotech Geoenviron Eng 124(2):140–149

Zhang Z, Wang Y-H (2015) Three-dimensional DEM simulations of monotonic jacking in sand. Granul Matter 17(3):359–376

Zhou H, Liu H, Kong G, Cao Z (2014) Analytical solution for pressure-controlled elliptical cavity expansion in elastic–perfectly plastic soil. Geotech Lett 4(2):72–78

Zhuang P-Z, Yu H-S, Hu N (2018) Size-dependent finite strain analysis of cavity expansion in frictional materials. Int J Solids Struct 150:282–294

Acknowledgement

This material is based on work supported by the National Science Foundation (NSF) under NSF CMMI 1849674. The authors also would like to thank program manager Dr. Richard Fragaszy for his support. Any opinions, findings and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect those of the NSF. The authors also would like to thank the two anonymous reviewers, whose comments and suggestions greatly helped us improve the overall quality of the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, S., Tao, J. Modeling Clam-inspired Burrowing in Dry Sand using Cavity Expansion Theory and DEM. Acta Geotech. 15, 2305–2326 (2020). https://doi.org/10.1007/s11440-020-00918-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-00918-8