Abstract

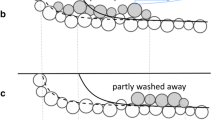

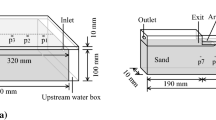

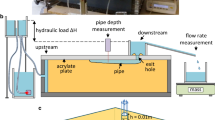

Backward erosion piping is an important failure mechanism for water-retaining structures. It results in the formation of shallow pipes at the interface of a sandy or silty foundation and a cohesive cover layer. This paper analyzes the depth of these erosion pipes through small-scale experiments. The development of the pipe depth reveals a lot of information on the backward erosion process, but it had never been measured systematically during the erosion process. Our analysis shows that the pipes are extremely shallow (in the order of mm) and that the pipe depth increases slightly, as piping progresses. Furthermore, a relation is found between pipe depth, grain size, soil permeability, and pipe length. The experimentally obtained depths are in good agreement with those obtained with theoretically determined pipe depths based on pipe hydraulics. Finally, the experiments are compared to 2D numerical simulations using Sellmeijer’s mathematical model and 3D numerical simulations with the correct pipe dimensions.

Similar content being viewed by others

Abbreviations

- A :

-

Cross section (mm2)

- B :

-

Pipe width (mm)

- CFD:

-

Coupled fluid dynamics

- C u :

-

Coefficient of uniformity (−)

- C c :

-

Coefficient of gradation (−)

- d 10 :

-

Diameter for which 10% of the particles of the distribution are smaller (mm)

- d 30 :

-

Diameter for which 30% of the particles of the distribution are smaller (mm)

- d 50 :

-

Average grain size (mm)

- d 60 :

-

Diameter for which 60% of the particles of the distribution are smaller (mm)

- d 80 :

-

Diameter for which 80% of the particles of the distribution are smaller (mm)

- d :

-

Pipe depth (m)

- d avg :

-

Average (of cross section) pipe depth (mm)

- \(d_{{{\text{avg}}, \Delta x}}\) :

-

Average pipe depth at a distance Δx from the pipe tip (calculated) (mm)

- DEM:

-

Discrete element method

- ΔH :

-

Hydraulic head difference (m)

- ΔH crit :

-

Critical hydraulic head for progression (m)

- ΔP/L :

-

Pressure drop per meter (Pa/m)

- Δx :

-

Distance from pipe tip (m)

- FEM:

-

Finite-element method

- γ w :

-

Unit density of water (N/m3)

- γ′ p :

-

Submerged unit density of particles (N/m3)

- k :

-

Hydraulic permeability (m/s)

- L :

-

Pipe length (m)

- M 0 :

-

Correction factor (−)

- Μ :

-

Dynamic viscosity (Pa s)

- η :

-

Coefficient of white (−)

- P w :

-

Wetted perimeter (m)

- φ′:

-

Effective friction angle of the sand (°)

- Q :

-

Flow rate (mm3/s)

- Q 2D :

-

Flow rate in 2D (Sellmeijer) (m2/s)

- ρ :

-

Unit density (kg/m3)

- Re :

-

Reynolds number (−)

- R h :

-

Hydraulic radius (m)

- θ :

-

Bedding angle (°)

- v :

-

Flow velocity (m/s)

- x :

-

Horizontal coordinate along piping direction (m)

- y :

-

Horizontal coordinate perpendicular to piping direction (m)

- z :

-

Vertical coordinate

References

Benjasuppatananan S, Meehaln CL (2013) Analytical solutions for levee underseepage analysis: straight and curved levee sections with an infinite blanket. In: Geo-congress. pp 1129–1138

Bligh WG (1915) Submerged weirs founded on sand. In: Dams and weirs: an analytical and practical treatise on gravity dams and weirs; arch and buttress dams, submerged weirs; and barrages. Chicago, pp 151–179

De Wit JM, Sellmeijer JB, Penning A (1981) Laboratory testing on piping. In: Paper presented at the tenth international conference on soil mechanics and foundation engineering, Stockholm, Sweden

El Shamy U, Aydin F (2008) Multiscale modeling of flood-induced piping in river levees. J Geotech Geoenviron Eng 134(9):1385–1398. https://doi.org/10.1061/(asce)1090-0241(2008)134:9(1385)

GeoDelft (2002) MSeep User Manual. Release 6.7

Glynn E, Quinn M, Kuszmaul J (2012) Predicting piping potential along middle Mississippi river levees. In: ICSE6, Paris

Hanses U, Müller-Kirchenbauer H, Savidis S (1985) Zur Mechanik der rückschreitenden Erosion unter Deichen und Dämmen. Bautechnik, 62nd edn. Wilhelm Ernst & Sohn, Berlin

Lane EW (1935) Security from under-seepage-masonry dams on earth foundations. Trans Am Soc Civ Eng 100(1):1235–1272

Miesel D (1978) Rückschreitende Erosion unter bindiger Deckschicht. In: Berlin

Morgan RPC (2005) Soil erosion and conservation. Blackwell Publishing, Hoboken

Ojha CSP, Singh VP, Adrian DD (2003) Determination of critical head in soil piping. J Hydraul Eng 129(7):511–518. https://doi.org/10.1061/(asce)0733-9429(2003)129:7(511)

Schmertmann JH (2000) The no-filter factor of safety against piping through sands. ASCE judgment and innovation at the heritage and future of the geotechnical engineering profession, p 68

Sellmeijer JB (1981) Piping due to flow towards ditches and holes. In: Verruijt A, Barends FBJ (eds) Flow and transport in porous media. In: Proceedings of Euromech 143, Delft, the Netherlands. CRC Press, Boca Raton, FL, USA

Sellmeijer JB (1988) On the mechanism of piping under impervious structures. TU Delft, Delft

Sellmeijer JB, Koenders MA (1991) A mathematical model for piping. Appl Math Model 15(11–12):646–651

Sellmeijer JB, Calle EOF, Sip JW (1989) Influence of aquifer thickness on piping below dikes and dams. In: International symposium on analytical evaluation of dam related safety problems, Copenhagen, Denmark, pp 357–366

Sellmeijer H, de la Cruz JL, van Beek VM, Knoeff H (2011) Fine-tuning of the backward erosion piping model through small-scale, medium-scale and IJkdijk experiments. Eur J Environ Civ Eng 15(8):1139–1154. https://doi.org/10.3166/ejece.15.1139-1154

Shields A (1936) Anwendung der Aehnlichkeitsmechanik und der Turbulenzforschung auf die Geschiebebewegung. Berlin

van Beek VM, Knoeff JG, Rietdijk J, Sellmeijer JB, Lopez de la Cruz J (2010) Influence of sand and scale on the piping process: experiments and multivariate analysis. In: Paper presented at the physical modelling in geotechnics, London

van Beek VM, Knoeff H, Sellmeijer H (2011) Observations on the process of backward erosion piping in small-, medium- and full-scale experiments. Eur J Environ Civ Eng 15(8):1115–1137. https://doi.org/10.3166/ejece.15.1115-1137

van Beek VM, Yao Q, Van M, Barends FBJ (2012) Validation of Sellmeijer’s model for backward erosion piping under dikes on multiple sand layers. In: ICSE6, Paris. pp 543–550

van Beek VM, Bezuijen A, Sellmeijer H (2013) Backward erosion piping. In: Bonelli S (ed) Erosion in geomechanics applied to dams and levees, vol 1. Wiley, London, pp 193–269

van Beek VM, Vandenboer K, Bezuijen A (2014) Influence of sand type on pipe development in small- and medium-scale experiments. In: Paper presented at the ICSE2014, Perth

van Beek VM, Essen HM, Vandenboer K, Bezuijen A (2015) Developments in modelling of backward erosion piping. Géotechnique 65(9):740–754. https://doi.org/10.1680/geot.14.P.119

Van Rhee C, Bezuijen A (1992) Influence of seepage on stability of sandy slope. J Geotech Eng-ASCE 118(8):1236–1246

Vandenboer K, van Beek VM, Bezuijen A (2013) 3D FEM simulation of groudwater flow during backward erosion piping. In: 5th international young geotechnical engineers’ conference, Paris, France. Ios Press, Amsterdam, The Netherlands, pp 301–304. https://doi.org/10.3233/978-1-61499-297-4-301

Vandenboer K, Bezuijen A, van Beek VM (2014) 3D character of backward erosion piping: small-scale experiments. In: Cheng L, Draper S, An H (eds) 7th international conference on scour and erosion, Perth. Taylor & Francis, pp 81–86

Vorogushyn S, Merz B, Apel H (2009) Development of dike fragility curves for piping and micro-instability breach mechanisms. Nat Hazards Earth Syst Sci 9(4):1383–1401

Wyseure G (2002) Stroming van Vloeistoffen (trans: Wetenschappen FLeTB). Fysische transportverschijnselen. KU Leuven

Acknowledgements

The authors are grateful to Sibelco Belgium for providing some of the sands.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vandenboer, K., van Beek, V.M. & Bezuijen, A. Analysis of the pipe depth development in small-scale backward erosion piping experiments. Acta Geotech. 14, 477–486 (2019). https://doi.org/10.1007/s11440-018-0667-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-018-0667-0