Abstract

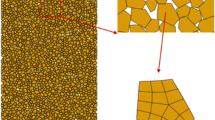

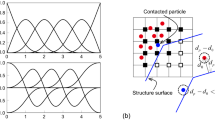

The post-construction settlement of rockfill dams and high filled ground of airport, which is a phenomenon of much significance, is mainly caused by the time-dependent breakage of the rockfill material. In this paper, a random virtual crack DEM model is proposed for creep behavior of rockfill in PFC2D according to the theory of subcritical crack propagation induced by stress corrosion mechanisms. The bonded clusters are adopted to represent the rockfill particles so as to simulate their irregular shapes. Virtual cracks are set at the bonds of the clusters, and the length of the crack is considered as a random value, which leads the crushing strength of a single particle to follow the Weibull’s statistical model and the corresponding size rules. Oedometric creep tests for rockfill are simulated by using this proposed model. The results show that the model, validated preliminarily by some test data, can reflect qualitatively the creep mechanism as well as the size effects reasonably. Particles can develop various breakage patterns during creep, including global breakage, local breakage and even complex mixed breakage. The increase in stress levels and particle size will lead to an obvious growth of the creep strain and creep rate of the rockfill. The scale effects on the creep behavior of rockfill are analyzed through 35 specimens, and formulas including the effects of scales and stress levels are tentatively proposed.

Similar content being viewed by others

References

Alaei E, Mahboubi A (2012) A discrete model for simulating shear strength and deformation behaviour of rockfill material, considering the particle breakage phenomenon. Granul Matter 14(6):707–717. doi:10.1007/s10035-012-0367-7

Alonso EE, Oldecop L, Pinyol NM (2009) Long term behaviour and size effects of coarse granular media. Mechanics of natural solids. Springer, Berlin Heidelberg, pp 255–281

Alonso EE, Olivella S, Pinyol NP (2005) A review of Beliche dam. Geotechnique 55(4):267–285. doi:10.1680/geot.2005.55.4.267

Alonso EE, Tapias M, Gini J (2012) Scale effects in rockfill behaviour. Géotech Lett 2(3):155–160. doi:10.1680/geolett.12.00025

Altuhafi FN, Coop MR (2010) Changes to particle characteristics associated with the compression of sands. Géotechnique 61(6):459–471. doi:10.1680/geot.9.P.114

Ashby MF, Jones RH (1998) Engineering materials 2: An introduction to microstructures, processing and design. Butterworth-Heinemann, Oxford, UK, pp 178–182

Atkinson BK, Meredith PG (1987) Experimental fracture mechanics data for rocks and minerals. In: Atkinson BK (ed) Fracture mechanics of rock. Academic Press, London, pp 477–525

Atkinson BK, Meredith PG (1987) The theory of subcritical crack growth with applications to minerals and rocks. In: Atkinson BK (ed) Fracture mechanics of rock. Academic Press, London, pp 111–166

Broek D (1986) Elementary engineering fracture mechanics. Martinus Nijhoff, Dordrecht

Cao GX (2011) Study on post-construction settlement of high filled foundation in mountainous airport. PhD thesis, Tsinghua University, Beijing, China

Cavarretta I, O’sullivan C (2012) The mechanics of rigid irregular particles subject to uniaxial compression. Geotechnique 62(8):681–692. doi:10.1680/geot.10.P.102

Charles RJ (1958) Static fatigue of glass. J Appl Phys 29(11):1549–1560

Cheng YP, Nakata Y, Bolton MD (2003) Discrete element simulation of crushable soil. Géotechnique 53(7):633–641. doi:10.1680/geot.2003.53.7.633

Cil MB, Alshibli KA (2014) 3D evolution of sand fracture under 1D compression. Géotechnique 64(5):351–364. doi:10.1680/geot.13.P.119

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29(1):47–65. doi:10.1680/geot.1979.29.1.47

Couroyer C, Ning Z, Ghadiri M (2000) Distinct element analysis of bulk crushing: effect of particle properties and loading rate. Powder Technol 109(1):241–254. doi:10.1016/S0032-5910(99)00240-5

Deluzarche R, Cambou B (2006) Discrete numerical modelling of rockfill dams. Int J Numer Anal Meth Geomech 30(11):1075–1096. doi:10.1002/nag.514

Erdogan F, Sih GC (1963) On the crack extension in plates under plane loading and transverse shear. J Fluids Eng 85(4):519–525. doi:10.1115/1.3656897

Freiman SW (1984) Effects of chemical environments on slow crack growth in glasses and ceramics. J Geophys Res 89(B6):4072–4076. doi:10.1029/JB089iB06p04072

Hagerty MM, Hite DR, Ullrich CR, Hagerty DJ (1993) One dimensional high pressure compression of granular media. J Geotech Eng 119(1):1–18. doi:10.1061/(ASCE)0733-9410(1993)119:1(1)

Hardin BO (1985) Crushing of soil particles. J Geotech Eng 111(10):1177–1192. doi:10.1061/(ASCE)0733-9410(1985)111:10(1177)

Head KH (1994) Manual of soil laboratory testing. Vol. 2: compressibility, shear strength and permeability (2nd edn). Pentech Press, London

Indraratna B, Ionescu D, Christie HD (1998) Shear behavior of railway ballast based on large-scale triaxial tests. J Geotech Geoenviron Eng 124(5):439–449. doi:10.1061/(ASCE)1090-0241(1998)124:5(439)

Itasca (2002) PFC2D v.3.0. Itasca Consulting Group Inc, Minneapolis, MN

Jiang H, Xu M (2014) Study of stress-path-dependent behavior of rockfills using discrete element method. Eng Mech 31(10):151–157. doi:10.6052/j.issn.1000-4750.2013.04.0382 (in Chinese)

Jiang MJ, Zhu FY, Liu F, Utili S (2014) A bond contact model for methane hydrate-bearing sediments with interparticle cementation. Int J Numer Anal Methods Geomech 38(5):1823–1854. doi:10.1002/nag.2283

Kwok CY, Bolton MD (2010) DEM simulations of thermally activated creep in soils. Géotechnique 60(6):425–433. doi:10.1680/geot.2010.60.6.425

Kwok CY, Bolton MD (2013) DEM simulations of soil creep due to particle crushing. Géotechnique 63(16):1365–1376. doi:10.1680/geot.11.P.089

Lade PV, Yamamuro JA, Bopp PA (1996) Significance of particle crushing in granular materials. J Geotech Eng 122(4):309–316. doi:10.1061/(ASCE)0733-9410(1996)122:4(309)

Lee KL, Farhoomand I (1967) Compressibility and crushing of granular soil in anisotropic triaxial compression. Can Geotech J 4(1):68–86. doi:10.1139/t67-012

Lim WL, McDowell GR (2005) Discrete element modelling of railway ballast. Granular Matter 7(1):19–29. doi:10.1007/s10035-004-0189-3

Lobo-Guerrero S, Vallejo LE (2005) Discrete element method evaluation of granular crushing under direct shear test conditions. J Geotech Geoenviron Eng 131(10):1295–1300. doi:10.1061/(ASCE)1090-0241(2005)131:10(1295)

Lobo-Guerrero S, Vallejo LE (2006) Application of Weibull statistics to the tensile strength of rock aggregates. J Geotech Geoenviron Eng 132(6):786–790. doi:10.1061/(ASCE)1090-0241(2006)132:6(786)

Lobo-Guerrero S, Vallejo LE, Vesga LF (2006) Visualization of crushing evolution in granular materials under compression using DEM. Int J Geomech 6(3):195–200. doi:10.1061/(ASCE)1532-3641(2006)6:3(195)

Lu M, McDowell GR (2010) Discrete element modelling of railway ballast under monotonic and cyclic triaxial loading. Géotechnique 60(6):459–467. doi:10.1680/geot.2010.60.6.459

Ma G, Zhou W, Ng TT, Cheng YG, Chang XL (2015) Microscopic modeling of the creep behavior of rockfills with a delayed particle breakage model. Acta Geotech. doi:10.1007/s11440-015-0367-y

Marachi ND, Chan CK, Seed HB, Duncan JM (1969) Strength and deformation characteristics of rockfill materials. University of California, Berkeley, CA, Report TE-69-5

Marachi ND, Chan CK, Seed HB (1972) Evaluation of properties of rockfill materials. J Soil Mech Found Eng Div ASCE 98(1):95–114

Marketos G, Bolton MD (2009) Compaction bands simulated in discrete element models. J Struct Geol 31(5):479–490. doi:10.1016/j.jsg.2009.03.002

Marsal RJ (1967) Large-scale testing of rockfill materials. J Soil Mech Found Eng Div ASCE 93(2):27–44

Marsal RJ (1973) Mechanical properties of rockfill. In: Hirshfield RC, Poulos SJ (eds) Embankment-dam engineering, casagrande volume. Wiley, New York, pp 109–200

McDowell GR, Amon A (2000) The application of Weibull statistics to the fracture of soil particles. Soils Found 40(5):133–141

McDowell GR, Bolton MD (1998) On the micro mechanics of crushable aggregates. Géotechnique 48(5):667–679. doi:10.1680/geot.1998.48.5.667

McDowell GR (2001) A probabilistic approach to sand particle crushing in the triaxial test. Géotechnique 51(3):285–287. doi:10.1680/geot.1999.49.5.567

McDowell GR (2001) Statistics of soil particle strength. Geotechnique 51(10):897–900

Nakata Y, Hyodo M, Hyde AFL, Kato Y, Murata H (2001) Microscopic particle crushing of sand subjected to high pressure one-dimensional compression. Soils Found 41(1):69–82. doi:10.3208/sandf.41.69

Nobari ES, Duncan MJ (1972) Effect of reservoir filling on stresses and movements in earth and rockfill dams. University of California, Berkeley, CA, Report TE-72-1

Oldecop LA, Alonso EE (2001) A model for rockfill compressibility. Géotechnique 51(2):127–139. doi:10.1680/geot.2001.51.2.127

Oldecop LA, Alonso EE (2007) Theoretical investigation of the time-dependent behaviour of rockfill. Géotechnique 57(5):423–435. doi:10.1680/geot.2007.57.3.289

Ortega E (2010) Comportamiento de materiales granulares gruesos - efecto de la succion. PhD thesis, Technical University of Catalonia, UPC, Barcelona

Robertson D, Bolton MD (2001) DEM simulations of crushable grains and soils. Proceedings of the 4th international conference on micromechanics of powders and grains, Sendai, Japan, pp 623–626

Seyedi HE, Mirghasemi AA (2006) Numerical simulation of breakage of two-dimensional polygon-shaped particles using discrete element method. Powder Tech 166(2):100–112. doi:10.1016/j.powtec.2006.05.006

Shao L (2013) Study on rheological property of rockfill by meso-mechanics simulation based on sub-critical crack expansion theory. PhD thesis, Dalian University of Technology, Dalian, China

Shao L, Chi SC, Zhang Y, Tao JY (2013) Study of triaxial shear tests for rockfill based on particle flow code. Rock Soil Mech 34(3):711–720 (in Chinese)

Sherard JL, Cooke JB (1987) Concrete-face rockfill dam: I. Assessment. J Geotech Geoenviron Eng 113(10):1096–1112. doi:10.1061/(ASCE)0733-9410(1987)113:10(1096)

Sowers GF, Williams RC, Wallace TS (1965) Compressibility of broken rock and settlement of rockfills. In: Proceeding of the 6th Int Conf Soil Mech Found Engng, Montreal; vol II, pp 561–565

Tada H, Paris PC, Irwin GR (1985) The stress analysis of cracks handbook, 2nd edn. Paris Productions, St. Louis, MO

Tran TH, Venier R, Cambou B (2009) Discrete modelling of rock-ageing in rockfill dams. Comput Geotech 36(1):264–275. doi:10.1016/j.compgeo.2008.01.005

Weibull W (1951) A statistical distribution function of wide applicability. ASME J Appl Mech 18(3):293–297

Wiederhorn SM, Fuller ER, Thomson R (1980) Micromechanisms of crack growth in ceramics and glasses in corrosive environments. Met Sci 14:450–458. doi:10.1179/msc.1980.14.8-9.450

Xu M, Song EX, Chen JF (2012) A large triaxial investigation of the stress-path-dependent behavior of compacted rockfill. Acta Geotech 7(3):167–175. doi:10.1007/s11440-012-0160-0

Acknowledgments

The work reported in this paper is financially supported by the National Key Fundamental Research and Development Program of China (Project No. 2014CB047003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, M., Song, E. A random virtual crack DEM model for creep behavior of rockfill based on the subcritical crack propagation theory. Acta Geotech. 11, 827–847 (2016). https://doi.org/10.1007/s11440-016-0446-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-016-0446-8