Abstract

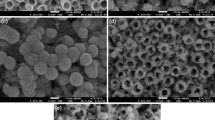

Quantum-sized CdS-coated TiO2 nanotube array (Q-CdS-TiO2 NTA) was fabricated by the modified successive ionic layer absorption and reaction method. Scanning electron microscope and transmission electron microscope images showed the regular structure of TiO2 NTA, where quantum-sized CdS (diameter <10 nm) deposited on both the inside and outside of TiO2 nanotube wall. Fabrication conditions including immersing cycles, calcination temperature and drying process were well optimized, and the Q-CdS-TiO2 NTA and its photoelectrochemical (PEC) properties were characterized by X-ray fluorescence spectrometer, UV–Vis diffuse reflectance spectra and photovoltage. Distinct increases in visible light absorption and photocurrent were observed as the immersing cycle was increased from 5 to 20 times. The additional drying process accelerated the CdS crystal growth rate, and thus, the fabrication time could be shortened accordingly. Calcination temperature influenced the PEC property of Q-CdS-TiO2 NTA deeply, and the optimized calcination temperature was found as 500 °C. As the Q-CdS-TiO2 NTA was fabricated under such condition, the visible photocurrent density increased to 2.8 mA/cm and the photovoltage between 350 and 480 nm was enhanced by 2.33 times than that without calcination. This study is expected to optimize Q-CdS-TiO2 NTA fabrication conditions for the purpose of improving its PEC performance.

抽象

本文采用改进的连续离子层吸附反应法(SILAR)制备了CdS量子点包覆的TiO2纳米管阵列(Q-CdS-TiO2 NTA)。扫描电子显微镜和透射电子显微镜结果表明,TiO2纳米管为有序阵列结构,CdS颗粒沉积在TiO2纳米管的内壁和外壁上,粒径小于10 nm。改变浸渍循环次数、焙烧温度以及干燥方法,并用X射线荧光光谱仪、紫外-可见分光光度计和光电压谱仪测试Q-CdS-TiO2 NTA样品的光电化学(PEC)性能,从而获得最优制备参数。浸渍循环次数从5次增加到20次时,Q-CdS-TiO2 NTA可见光吸附和光电流明显增大。干燥过程能够加快CdS晶体生长速度,缩短制备时间。与未焙烧的Q-CdS-TiO2 NTA相比,500 °C焙烧制备的Q-CdS-TiO2 NTA可见光电流密度增大至2.8 mA/cm2,350–480 nm间的光电压提高了2.33倍。上述研究结果为制备此类量子点包覆阵列材料提供了参考。

Similar content being viewed by others

References

Bai Y, Mora-Sero L, De Angelis F et al (2014) Titanium dioxide nanomaterials for photovoltaic applications. Chem Rev 114:10095–10130

Daghrir R, Drogui P, Robert D (2013) Modified TiO2 for environmental photocatalytic applications: a review. Ind Eng Chem Res 52:3581–3599

Quan X, Yang SG, Ruan XL et al (2005) Preparation of titania nanotubes and their environmental applications as electrode. Environ Sci Technol 39:3770–3775

Wu N, Wang J, Tafen D et al (2010) Shape-enhanced photocatalytic activity of single-crystalline anatase TiO2 (101) nanobelts. J Am Chem Soc 132:6679–6685

Chen C, Cai W M, Long M C et al (2010) Synthesis of visible-light responsive graphene oxide/TiO2 composites with p/n heterojunction. ACS Nano 4:6425–6432

Asahi R, Morikawa T, Ohwaki T et al (2001) Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 293:269–271

Schneider J, Matsuoka M, Takeuchi M et al (2014) Understanding TiO2 photocatalysis: mechanisms and materials. Chem Rev 114:9919–9986

Li JY, Lu N, Quan X et al (2008) Facile method for fabricating boron-doped TiO2 nanotube array with enhanced photoelectrocatalytic properties. Ind Eng Chem Res 47:3804–3808

Liu L, Chen XB (2014) Titanium dioxide nanomaterials: self-structural modifications. Chem Rev 114:9890–9918

Peng ZA, Peng XG (2001) Formation of high-quality CdTe, CdSe, and CdS nanocrystals using CdO as precursor. J Am Chem Soc 123:183–184

Alivisatos AP (1996) Semiconductor clusters, nanocrystals, and quantum dots. Science 271:933–937

Li YF, Liu ZP (2011) Particle size, shape and activity for photocatalysis on titania anatase nanoparticles in aqueous surroundings. J Am Chem Soc 133:15743–15752

Larramona G, Chone C, Jacob A et al (2006) Nanostructured photovoltaic cell of the type titanium dioxide, cadmium sulfide thin coating, and copper thiocyanate showing high quantum efficiency. Chem Mater 18:1688–1696

Luo JS, Ma L, He TC et al (2012) TiO2/(CdS, CdSe, CdSeS) nanorod heterostructures and photoelectrochemical properties. J Phys Chem C 116:11956–11963

Chen SG, Paulose M, Ruan C et al (2006) Electrochemically synthesized CdS nanoparticle-modified TiO2 nanotube-array photoelectrodes: preparation, characterization, and application to photoelectrochemical cells. J Photochem Photobiol A 177:177–184

Biswas S, Hossain MF, Takahashi T (2008) Fabrication of Gratzel solar cell with TiO2/CdS bilayered photoelectrode. Thin Solid Films 517:1284–1288

Lokhande CD, Sankapal BR, Sartale SD et al (2001) A novel method for the deposition of nanocrystalline Bi2Se3, Sb2Se3 and Bi2Se3–Sb2Se3 thin films-SILAR. Appl Surf Sci 182:413–417

Kundakci M, Ates A, Astam A et al (2008) Structural, optical and electrical properties of CdS, Cd0.5In0.5S and In2S3 thin films grown by SILAR method. Physica E 40:600–605

Sun WT, Yu Y, Pan H et al (2008) CdS quantum dots sensitized TiO2 nanotube-array photoelectrodes. J Am Chem Soc 130:1124–1125

Lu N, Quan X, Li JY et al (2007) Fabrication of boron-doped TiO2 nanotube array electrode and investigation of its photoelectrochemical capability. J Phys Chem C 111:11836–11842

Peng XG, Wickham J, Alivisatos AP (1998) Kinetics of II–VI and III–V colloidal semiconductor nanocrystal growth: “focusing” of size distributions. J Am Chem Soc 120:5343–5344

Acknowledgments

This work was supported by the National Natural Science Foundation of China (21377020) and the Fundamental Research Funds for the Central Universities (DUT15QY17).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Lu, N., Su, Y., Li, J. et al. Fabrication of quantum-sized CdS-coated TiO2 nanotube array with efficient photoelectrochemical performance using modified successive ionic layer absorption and reaction (SILAR) method. Sci. Bull. 60, 1281–1286 (2015). https://doi.org/10.1007/s11434-015-0841-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11434-015-0841-9