Abstract

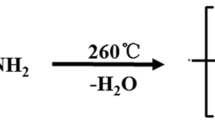

The copolymerization of propylene and 5-hexenyl-9-borabicyclo[3.3.1]nonane (5-hexenyl-9-BBN) has been conducted with an MgCl2/TiCl4 catalyst intercalated in an organically modified montmorillonite (OMMT) with triethylaluminum (AlEt3) cocatalyst and diphenyldimethoxysilane (DDS) external donor. This polymerization process simultaneously results in both the exfoliation of MMT layers to realize the preparation of polypropylene (PP)/MMT nanocomposites and the implantation of reactive borane groups in the formed PP matrix. The polymer-borne borane groups have been able to undergo an efficient hydrolysis process under very mild reaction conditions (40°C, 3 h, in THF), introducing hydroxy groups into PP without sacrificing the polymerization-formed nanocomposite structure (the exfoliation of MMT). The resultant hydroxyl-functionalized PP/MMT nanocomposites exhibit enhanced structural stability against processing compared with those based on unfunctionalized PP matrix.

Similar content being viewed by others

References

Wagenknecht U, Kretzschmar B, Reinhardt G Investigations of fire retardant properties of polypropylene-clay-nanocomposites. Macromol Symp, 2003, 194: 207–212

Kawasumi M, Hasegawa N, Kato M, et al. Preparation and mechanical properties of polypropylene-clay hybrids. Macromolecules, 1997, 30(20): 6333–6338

Manias E, Wu T L, Strawhecker K. Polypropylene/montmorillonite nanocomposites. Review of the synthetic routes an materials properties. Chem Mater, 2001, 13(10): 3516–3523

Liu X H, Wu Q J. PP/clay nanocomposites prepared by grafting-melt. Polymer, 2001, 42: 10013–10019

García-López D, Picazo O, Merino J C, et al. Polypropylene-clay nanocomposites: effect of compatibilizing agents on clay dispersion. Eur Polym J, 2003, 39: 945–950

Zhang J G, Jiang D D, Wilkie C A. Polyethylene and polypropylene nanocomposites based upon an oligomerically modified clay. Thermochimica Acta, 2005, 430: 107–113

Hasegawa N, Kawasumi M, Kato M. Preparation and mechanical properties of polypropylene-clay hybrids using maleic anhydride intercalation-modified polypropylene oligomer. J Appl Polym Sci, 1998, 67: 87–92

Usuki A, Kato M, Okada A, et al. Synthesis of polypropylene-clay hybrid. J Appl Polym Sci, 1997, 63: 137–139

Kato M, Usuki A, Okada A. Synthesis of polypropylene oligomerclay intercalation compounds. J Appl Polym Sci, 1997, 66: 1781–1785

Oya A, Kurokawa Y, Yasuda H. Factors controlling mechanical properties of clay mineral/propylene nanocomposites. J Mater Sci, 2000, 35: 1045–1050

Sun T, Garcés M J. High-performance polypropylene-clay nanocomposites by in situ polymerization with metallocene/clay catalysts. Adv Mater, 2002, 14: 128–130

Hwu J M, Jiang G J. Preparation and characterization of polypropylene-montomorillonite nanocomposites generated by in situ metallocene catalyst polymerization. J Appl Polym Sci, 2005, 95: 1228–1236

Ma J S, Qi Z N, Hu Y L. Synthesis and characterization of polypropylene/clay nanocomposites. J Appl Polym Sci, 2001, 82: 3611–3617

Weiss K, Wirth-Pfeifer C, Hofmann M, et al. Polymerization of ethylene or propylene with heterogeneous metallocene catalysts on clay minerals. J Molecu Catal A: Chem, 2002, 182–183: 143–149

He A H, Hu H Q, Huang Y J, et al. Isotactic poly(propylene)/monoalkylimidazolum-modified montmorillonite nanocomposites: Preparation by intercalative polymerization and thermal stability study. Macromol Rapid Commun, 2004, 25: 2008–2013

Qi Z N, Shang W Y. The Theory and Practice of Polymer/Layered Silicate Nanocomposites (in Chinese). Beijing: Chemical Industry Press, 2002. 20

Alexandre M, Dubois P, Sun T, et al. Polyethylene-layered silicate nanocomposites prepared by the polymerization-filling technique: Synthesis and mechanical properties. Polymer, 2002, 43: 2123–2132

Jin Y H, Park H J, Im S S, et al. Polyethylene/clay nanocomposite by in-situ exfoliation of montmorillonite during Zieglar-Natta polymerization of ethylene. Macromol Rapid Commun, 2002, 23: 135–140

Ramakrishnan S, Berluche E, Chung T C. Functional group containing copolymers prepared by the Zieglar-Natta process. Macromolecules, 1990, 23(2): 378–382

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by “One Hundred Talents Program” of the Chinese A cademy of Sciences, the National Natural Science Foundation of China (Grant Nos. 20304017, 50373408 and 50573081) and National “973” Project (Grant No. G2003CB615605)

About this article

Cite this article

Yang, K., Huang, Y. & Dong, J. Preparation of polypropylene/montmorillonite nanocomposites by intercalative polymerization: Effect of in situ polymer matrix functionalization on the stability of the nanocomposite structure. CHINESE SCI BULL 52, 181–187 (2007). https://doi.org/10.1007/s11434-007-0017-3

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11434-007-0017-3