Abstract

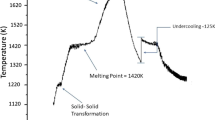

The high undercooling and rapid solidification of Ni-10%Cu-10%Fe-10%Co quaternary alloy were achieved by electromagnetic levitation and glass fluxing techniques. The maximum undercooling of 276 K (0.16TL) was obtained in the experiments. All the solidified samples are determined to be α-Ni single-phase solid solutions by DSC thermal analysis and X-ray diffraction analysis. The microstructure of the α-Ni solid solution phase transfers from dendrite to equiaxed grain with an increase in undercooling, accompanied by the grain refinement effect. When the undercooling is very large, the solute trapping effect becomes quite significant and the microsegregation is suppressed. The experimental measurement of α-Ni dendrite growth velocity indicates that it increases with undercooling according to the relation, V=8×10−2×ΔT 1.2.

Similar content being viewed by others

References

Bisang U, Bilgram J H. Shape of the tip and the formation of sidebranches of xenon dendrites. Phys Rev E, 1996, 54(5): 5309–5326

Arnold C B, Aziz M J, Schwarz M, et al. Toward a parameter-free test of dendrite growth theory. Phys Rev B, 1999, 59(1): 334–343

Hürlimann E, Trittibach R, Risang U, et al. Intergral parameter of xenon dendrites. Phys Rev E, 1992, 46(10): 6579–6595

Lipton J, Kurz W, Trivedi R. Rapid dendrite growth in undercooled alloys. Acta Metall, 1987, 35(4): 957–964

Trivedi R, Lipton J, Kurz W. Effect of growth rate dependent partition coefficient on the dendritic growth in undercooled melts. Acta Metal, 1987, 35(4): 965–970

Yao W J, Han X J, Wei B. The undercooling and rapid dendritic growth of Cu-Sb in drop tube. Chin Sci Bull, 2002, 47(11): 824–828

Yao W J, Yang C, Han X J, et al. Rapid dendritic growth in an undercooled Ni-Cu alloy under the microgravity condition. Acta Physica Sinica, 2003, 52(2): 448–453

Hunziker O. Theory of plane front and dendritic growth in multicomponent alloys. Acta Mater, 2001, 49: 4191–4203

Ludwig A. The interface response-functions in multi-componental alloy solidification. Physica D, 1998, 124: 217–284

Ruan Y, Cao C D, Wei B. The rapid growth of ternary eutectic alloy at high undercooling. Sci China Ser G-Phys, 2004, 34(4): 392–402

Wang N, Wei B. Thermodynamic properties of highly undercooled liquid TiAl alloy. Appl Phys Lett, 2002, 80(19): 3515–3517

Subramanian P R, Laughlin D E. Binary Alloy Phase Diagrams (ed. Massalski T B), 1990. 1442

Swartzendruber L J, Itkin V P, Alock C B. Binary Alloy Phase Diagrams (ed. Massalski T B), 1990. 1735

Nishizawa T, Lshida K. Binary Alloy Phase Diagrams (ed. Massalski T B), 1990. 1215

Xie Y Q. Lattice constants of disordered and ordered phases in Au-Cu system. Acta Metall Sinica, 1998, 12(34): 1234–1242

Hofmeister W H, Bayuzick R J, Robinson M B. Dual purpose pyrometer for temperature and solidification velocity measurement. Rev Sci Instrum, 1990, 61: 222

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Song, X., Wang, H., Ruan, Y. et al. Rapid dendrite growth in quaternary Ni-based alloys. CHINESE SCI BULL 51, 897–901 (2006). https://doi.org/10.1007/s11434-006-0897-7

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11434-006-0897-7