Abstract

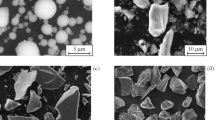

Sintered metals are characterized by the high porosity (⩾ 8%) and voids/micro-cracks in microns. Inelastic behavior of the materials is coupled with micro-crack propagation and coalescence of open voids. In the present work the damage evolution of the sintered iron under multi-axial monotonic loading conditions was investigated experimentally and computationally. The tests indicated that damage of the sintered iron initiated already at a stress level much lower than the macroscopic yield stress. The damage process can be divided into the stress-dominated elastic damage and the plastic damage described by the plastic strain. Based on the uniaxial tensile tests an elastic-plastic continuum damage model was developed which predicts both elastic damage and plastic damage in the sintered iron under general multi-axial monotonic loading conditions. Computational predictions agree with experiments with different multi-axial loading paths. A phenomenological continuum damage model for the sintered metal is developed based on the experimental observations to predict the inelastic behavior and damage process to failure under multi-axial loading conditions. The proposed damage model is experimentally verified under different loading conditions.

Similar content being viewed by others

References

Sonsino C M. Fatigue design principles for sintered steel components. J Strain Anal Eng Des, 2006, 41(7): 497–555

Sonsino C M. Zukunftsperspektiven für die Pulvermetallurgie durch die Betriebsfestigkeit. Materialwissenschaft Werkstofftechnik, 2006, 37(3): 240–248

Schneider M, Yuan H. Experimental and computational investigation of cyclic mechanical behavior of sintered iron. Comput Mater Sci, 2012, 57: 48–58

Zafari A, Beiss P. Effect of tensile mean stresses on fatigue strength of fe-cu-c steels in as-sintered and heat treated conditions. Powder Metall Prog, 2008, 8(3): 200–209

Chen J, Yuan H, Schneider M. Investigation of micromechanical deformation mechanisms in sinter powder metals. Adv Mater Res, 2013, 668: 351–355

Carabajar S, Verdu C, Fougeres R. Damage mechanisms of a nickel alloyed sintered steel during tensile tests. Mater Sci Eng A, 1997, 232(1–2): 80–87

Kabatova M, Dudrova E, Wronski S. Microcrack nucleation, growth, coalescence and propagation in the fatigue failure of a powder metallurgy steel. Fatigue Fracture Eng Mater Struct, 2009, 32(3): 214–222

Straffelini G, Molinari A. Evolution of tensile damage in porous iron. Mater Sci Eng A, 2002, 334(1–2): 96–103

Chawla N, Jester B, Vonk D. Bauschinger effect in porous sintered steels. Mater Sci Eng A, 2003, 346(1–2): 266–272

Chawla N, Deng X. Microstructure and mechanical behavior of porous sintered steels. Mater Sci Eng A, 2005, 390(1–2): 98–112

Besson J. Continuum models of ductile fracture: A review. Int J Damage Mech, 2010, 19(1): 3–52

Li H, Fu M, Lu J, et al. Ductile fracture: Experiments and computations. Int J Plast, 2011, 27(2): 147–180

Kintzel O, Khan S, Mosler J. A novel isotropic quasi-brittle damage model applied to LCF analyses of Al2024. Int J Fatigue, 2010, 32(12): 1948–1959

Pan X, Yuan H. Computational algorithms and applications of elementfree Galerkin methods for nonlocal damage models. Eng Fracture Mech, 2010, 77: 2640–2653

Yuan H, Chen J, Krompholz K, et al. Investigations of size effects in tensile tests based on a nonlocal micro-mechanical damage model. Comput Mater Sci, 2003, 26: 230–243

Chow C, Jie M. Anisotropic damage-coupled sheet metal forming limit analysis. Int J Damage Mech, 2008, 18(4): 371–392

Lemaitre J, Desmorat R. Engineering Damage Mechanics: Ductile, Creep, Fatigue and Brittle Failures. Berlin: Springer-Verlag, 2005

Voyiadjis G Z, Kattan P I. A comparative study of damage variables in continuum damage mechanics. Int J Damage Mech, 2008, 18(4): 315–340

Abu Al-Rub R K, Kim S-M. Computational applications of a coupled plasticity-damage constitutive model for simulating plain concrete fracture. Eng Fracture Mech, 2010, 77(10): 1577–1603

Desmorat R, Cantournet S. Modeling microdefects closure effect with isotropic/anisotropic damage. Int J Damage Mech, 2007, 17(1): 65–96

Voyiadjis G Z, Taqieddin Z N, Kattan P I. Anisotropic damage-plasticity model for concrete. Int J Plast, 2008, 24(10): 1946–1965

Lemaitre J. A Course on Damage Mechanics. Berlin: Springer-Verlag, 1996

Schneider M, Yuan H. Experimental and computational investigation of cyclic mechanical behavior and damage evolution of Distaloy AE + 0.5. Powder Metall Prog, 2011, 11: 141–148

Lubliner J. Plasticity Theory. San Antonio, TX: Pearson Education, Inc., 1990

Chaboche J L, Boudifa M, Saanouni K. A CDM approach of ductile damage with plastic compressibility. Int J Fracture, 2006, 137(1–4): 51–75

Pirondi A, Bonora N, Steglich D, et al. Simulation of failure under cyclic plastic loading by damage models. Int J Plast, 2006, 22(11): 2146–2170

Shao J, Jia Y, Kondo D, et al. A coupled elastoplastic damage model for semi-brittle materials and extension to unsaturated conditions. Mech Mater, 2006, 38(3): 218–232

Bonora N, Gentile D, Pirondi A, et al. Ductile damage evolution under triaxial state of stress: Theory and experiments. Int J Plast, 2005, 21(5): 981–1007

Cicekli U, Voyiadjis G Z, Abu Al-Rub R K. A plasticity and anisotropic damage model for plain concrete. Int J Plast, 2007, 23(10–1): 1874–1900

Castagne S, Habraken A, Cescotto S. Application of a damage model to an aluminium alloy. Int J Damage Mech, 2003, 12(1): 5–30

Kang G, Liu Y, Ding J, et al. Uniaxial ratcheting and fatigue failure of tempered 42CrMo steel: Damage evolution and damage-coupled viscoplastic constitutive model. Int J Plast, 2009, 25(5): 838–860

Khan S, Kintzel O, Mosler J. Experimental and numerical lifetime assessment of Al 2024 sheet. Int J Fatigue, 2012, 37: 112–122

Xue L, Wierzbicki T. Ductile fracture initiation and propagation modeling using damage plasticity theory. Eng Fracture Mech, 2008, 75(11): 3276–3293

Bonora N. A nonlinear CDM model for ductile failure. Eng Fracture Mech, 1997, 58(1): 11–28

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, H., Ma, S. & Zhang, L. Continuum damage mechanics for sintered powder metals. Sci. China Phys. Mech. Astron. 58, 1–12 (2015). https://doi.org/10.1007/s11433-014-5529-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-014-5529-7