Abstracts

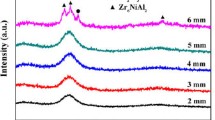

Ti42.5Zr7.5Cu40Ni5Sn5 bulk metallic glass with a critical diameter of 4 mm was fabricated by the conventional copper mould casting method. The supercooled liquid region ΔT x, reduced glass transition temperature T rg, γ parameter, and δ parameter of the alloy were measured to be 63.9 K, 0.561, 0.393, and 1.400, respectively, implying that the alloy has an excellent glass-forming ability. The bulk metallic glass exhibits high compressive fracture strength of 2162 MPa with distinct plastic strain of 0.9%. The fracture surface consists mainly of vein-like patterns, typical of bulk glassy alloys.

Similar content being viewed by others

References

Peker A, Johnson W L. A highly processing metallic glass: Zr41.2Ti13.8Cu12.5Ni10Be22.5. Appl Phys Lett, 1993, 63: 2342–2344

Liu Y H, Wang G, Wang R J, et al. Super plastic bulk metallic glasses at room temperature. Science, 2007, 315: 1385–1388

He L, Sun J. Effect of microalloying on glass-forming ability and crystallization kinetics of Zr52.5Cu17.9Ni14.6Al10Ti5 alloy. Script Mater, 2006, 54: 1081–1085

Jing Q, Liu R P, Shao G J, et al. Preparation and super-plastic deformation of the Zr-based bulk metallic glass. Mater Sci Eng A, 2003, 359: 402–404

Shen J, Chen Q J, Sun J F, et al. Exceptionally high glass-forming ability of an FeCoCrMoCBY alloy. Appl Phys Lett, 2005, 86: 151907

Choi-Yim H, Xu D H, Johnson W L. Ni-based bulk metallic glass formation in the Ni-Nb-Sn and Ni-Nb-Sn-X (X=B, Fe, Cu) alloy systems. Appl Phys Lett, 2003, 82: 1030–1032

Qiu C L, Chen Q, Liu L. A novel Ni-free Zr-based bulk metallic glass with enhanced plasticity and good biocompatibility. Script Mater, 2006, 55: 605–608

Xu D H, Duan G, Johnson W L. Unusual glass-forming ability of bulk amorphous alloys based on ordinary metal copper. Phys Rev Lett, 2004, 92(24): 245504

Dai C L, Guo H, Shen Y, et al. A new centimeter-diameter Cu-based bulk metallic glass. Script Mater, 2006, 54: 1403–1408

Zhang Q S, Zhang H F, Deng Y F, et al. Bulk metallic glass formation of Cu-Zr-Ti-Sn alloys. Script Mater, 2003, 49: 273–278

Guo F Q, Wang H J, Poon S J, et al. Ductile titanium-based glassy alloy ingots. Appl Phys Lett, 2005, 86: 091907

Inoue A, Kohinata M, Tsai A P, et al. Mg-Ni-La amorphous alloys with a wide supercooled liquid region. Mater Trans, 1989, 30(5): 378–381

Huang Y J, Shen J, Sun J F, et al. A new Ti-Zr-Hf-Cu-Ni-Si-Sn bulk amorphous alloy with high glass-forming ability. J Alloys Compd, 2007, 427: 171–175

Tanner L E, Ray R. Physical properties of Ti50Be40Zr10 glass. Script Metall, 1977, 11(9): 783–789

Inoue A, Nishiyama N, Amiya K, et al. Ti-based amorphous alloys with a wide supercooled liquid region. Mater Lett, 1994, 19(3–4): 131–135

Zhang T, Inoue A, Masumoto T. Amorphous (Ti, Zr, Hf)-Ni-Cu ternary alloys with a wide supercooled liquid region. Mater Sci Eng A, 1994, 181–182: 1423–1426

Zhang T, Inoue A. Thermal and mechanical properties of Ti-Ni-Cu-Sn amorphous alloys with a wide supercooled liquid region before crystallization. Mater Trans, 1998, 39(10): 1001–1006

Zhang T, Inoue A. Preparation of Ti-Cu-Ni-Si-B amorphous alloys with a large supercooled liquid region. Mater Trans, 1999, 40(4): 301–306

Kim Y C, Na J H, Park J M, et al. Role of nanometer-scale quasicrystals in improving the mechanical behavior of Ti-based bulk metallic glasses. Appl Phys Lett, 2003, 83(15): 3093–3095

Kissinger H E. Reaction kinetics in differential thermal analysis. Anal Chem, 1957, 29(11): 1702–1706

Inoue A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater, 2000, 48(1): 279–306

Turnbull D. Under what conditions can a glass be formed. Contemp Phys, 1969, 10(5): 473–488

Lu Z P, Liu C T. Glass formation criterion for various glass-forming systems. Phys Rev Lett, 2003, 91(11): 115505

Chen Q J, Shen J, Zhang D L, et al. A new criterion for evaluating the glass-forming ability of bulk metallic glasses. Mater Sci Eng A, 2006, 433: 155–160

Zhang T, Inoue A. Ti-based amorphous alloys with a large supercooled liquid region. Mater Sci Eng A, 2001, 304–306: 771–774

Kim Y C, Kim W T, Kim D H. A development of Ti-based bulk metallic glass. Mater Sci Eng A, 2004, 375–377: 127–135

Men H, Pang S J, Inoue A, et al. New Ti-based bulk metallic glasses with significant plasticity. Mater Trans, 2005, 46: 2218–2220

Wu X F, Suo Z Y, Si Y, et al. Bulk metallic glass formation in a ternary Ti-Cu-Ni alloy system. J Alloys Comp, 2006

Zhu S L, Wang X M, Qin F X, et al. A new Ti-based bulk glassy alloy with potential for biomedical application. Mater Sci Eng A, 2007, 459: 233–237

Takeuchi A, Inoue A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans, 2005, 46(12): 2817–2829

Zhang Z F, Eckert J, Schultz L. Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glass. Acta Mater, 2003, 51: 1167–1179

Liu C T, Heatherly L, Eaton D S, et al. Test environments and mechanical properties of Zr-base bulk amorphous alloys. Metall Mater Trans A, 1998, 29: 1811–1820

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the Program for New Century Excellent Talents in University of China and the National Natural Science Foundation of China (NSFC)(Grant No. 50771040)

Rights and permissions

About this article

Cite this article

Huang, Y., Shen, J. & Sun, J. Formation, thermal stability and mechanical properties of Ti42.5Zr7.5Cu40Ni5Sn5 bulk metallic glass. Sci. China Ser. G-Phys. Mech. As 51, 372–378 (2008). https://doi.org/10.1007/s11433-008-0049-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-008-0049-y