Abstract

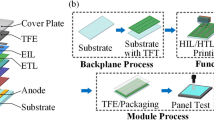

The emergence of new display devices, such as organic light-emitting diodes, has brought about numerous advantages, including high material utilization, low cost, and high adaptability. These devices are manufactured using inkjet printing and possess the potential to become a key technology for display transformations. However, a challenge in achieving this is the display effect that reveals uneven brightness and darkness, which can be avoided by controlling the volume of ink solution in a pixel to within 5%. Currently, the volume difference among the nozzles of commercial printheads does not meet the requirements for volume uniformity, thus challenging the printing process. Therefore, designing a suitable printing method that allows for the fusion of different volumes of ink droplets, ultimately reducing the error of the post fusion process, is necessary. In this study, we propose a print display droplet fusion scheduling method comprising two main steps. First, we use a dichotomous trust domain algorithm to obtain a feasible range of printhead docking point spacings for different nozzle and pixel panel resolutions. Second, we model the printing process as a droplet fusion scheduling model based on mixed integer programming, with the optimization objective of achieving intra pixel volume uniformity via ensuring the volume uniformity of ink droplets within all pixels. We verified this method through numerical simulations and printing experiments using 394 pixels per inch (ppi) pixel panels and successfully reduced the volume uniformity error among pixels to within 5%.

Similar content being viewed by others

References

Chen H W, Lee J H, Lin B Y, et al. Liquid crystal display and organic light-emitting diode display: Present status and future perspectives. Light Sci Appl, 2018, 7: 17168

Garner S, Chowdhury D, Lewis S. Ultrathin glass substrates for thin, lightweight, flexible OLED lighting. Inf Disp, 2019, 35: 9–13

Chowdhury D Q, Garner S M, Lewis S C. Application of OLED for automotive lighting. In: 2019 26th International Workshop on Active-Matrix Flatpanel Displays and Devices (AM-FPD). IEEE, 2019. 1–3

Yin Z P, Huang Y A, Bu N B, et al. Inkjet printing for flexible electronics: Materials, processes and equipments. Chin Sci Bull, 2010, 55: 3383–3407

Hu Z, Yin Y, Ali M U, et al. Inkjet printed uniform quantum dots as color conversion layers for full-color OLED displays. Nanoscale, 2020, 12: 2103–2110

Chen P Y, Chen C L, Chen C C, et al. 65-inch inkjet printed organic light-emitting display panel with high degree of pixel uniformity. In: SID Symposium Digest of Technical Papers’45. San Diego, CA, 2014. 396–398

Shao L Q, Liang J S, Bi Z T, et al. The development of 403 PPI real RGB printing AMOLED. In: SID Symposium Digest of Technical Papers’50. San Jose, CA: John Wiley and Sons, 2019. 43–1945

Solanki A, Awasthi A, Unni K N N, et al. An efficient and facile method to develop defect-free OLED displays. Semicond Sci Technol, 2021, 36: 065005

Lee J. Region-based machine learning for OLED mura defects detection. In: SID Symposium Digest of Technical Papers’52. San Jose, CA: John Wiley and Sons, 2021. 200–203

Tomita S, Siritanawan P, Kotani K. In-line mura detection using convolutional neural network in display manufacturing. In: SID Symposium Digest of Technical Papers’53. San Jose, CA: John Wiley and Sons, 2022. 963–966

Madigan C F, Hauf C R, Barkley L D, et al. 30.2: Invited paper: Advancements in inkjet printing for OLED mass production. In: SID Symposium Digest of Technical Papers’45. San Diego, CA: John Wiley and Sons, 2014. 399–402

Wang J, Chiu G T C. Control of drop volume and drop jetting velocity in inkjet printing. In: Proceedings of 9th IFAC Symposium on Mechatronic Systems (MECHATRONICS)/16th International Conference on Motion and Vibration Control (MoViC). Los Angeles, 2022. 37–43

Zhong Y, Fang H, Ma Q, et al. Analysis of droplet stability after ejection from an inkjet nozzle. J Fluid Mech, 2018, 845: 378–391

Cao X, Ye Y, Liu X, et al. Realization of uniform OLED pixels based on multi-nozzle by inkjet printing. In: SID Symposium Digest of Technical Papers’52. San Jose, CA: John Wiley and Sons, 2021. 395–397

Wang T, Kwok T H, Zhou C, et al. In-situ droplet inspection and closed-loop control system using machine learning for liquid metal jet printing. J Manuf Syst, 2018, 47: 83–92

Merklein L, Daume D, Braig F, et al. Comparative study of printed multilayer OLED fabrication through slot die coating, gravure and inkjet printing, and their combination. Colloids Interfaces, 2019, 3: 32

Zheng X, Liu Y, Zhu Y, et al. Efficient inkjet-printed blue OLED with boosted charge transport using host doping for application in pixelated display. Optical Mater, 2020, 101: 109755

Du Z, Liu Y, Xing X, et al. Inkjet printing multilayer OLEDs with high efficiency based on the blurred interface. J Phys D-Appl Phys, 2020, 53: 355105

Bail R, Hong J Y, Chin B D. Inkjet printing of blue phosphorescent light-emitting layer based on bis(3,5-di(9H-carbazol-9-yl))diphenylsilane. RSC Adv, 2018, 8: 11191–11197

Mao H, Jia W, Leung Y S, et al. Multi-material stereolithography using curing-on-demand printheads. Rapid Prototyping J, 2021, 27: 861–871

Jensen M L, Mahshid R, D’Angelo G, et al. Toolpath strategies for 5DOF and 6DOF extrusion-based additive manufacturing. Appl Sci, 2019, 9: 4168

Ezair B, Fuhrmann S, Elber G. Volumetric covering print-paths for additive manufacturing of 3D models. Comput-Aided Des, 2018, 100: 1–13

Jin G Q, Li W D, Gao L. An adaptive process planning approach of rapid prototyping and manufacturing. Robotics Comput-Integrated Manuf, 2013, 29: 23–38

Jin G Q, Li W D, Tsai C F, et al. Adaptive tool-path generation of rapid prototyping for complex product models. J Manuf Syst, 2011, 30: 154–164

Saraç T, Tutumlu B. A mix integer programming model and solution approach to determine the optimum machine number in the unrelated parallel machine scheduling problem. J Faculty Eng Architecture Gazi Univ, 2022, 37: 329–345

Xu Y, Wang X. A hybrid integer programming and artificial bee colony algorithm for staff scheduling in call centers. Comput Industrial Eng, 2022, 171: 108312

Wang T, Liu F, Cao X, et al. A mixed integer model for large-scale new energy medium-term operation problem. Int J Performability Eng, 2017, 13: 1381

Lin K, Zhao R, Xu Z, et al. Efficient large-scale fleet management via multi-agent deep reinforcement learning. In: Proceedings of the 24th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining’18. London, 2018. 1774–1783

Nair V, Bartunov S, Gimeno F, et al. Solving mixed integer programs using neural networks. 2020, arXiv: 2012.13349

Hjelmeland M N, Zou J, Helseth A, et al. Nonconvex medium-term hydropower scheduling by stochastic dual dynamic integer programming. IEEE Trans Sustain Energy, 2018, 10: 481–490

Xia Y, Wang L, Yang M. A fast algorithm for globally solving Tikhonov regularized total least squares problem. J Glob Optim, 2019, 73: 311–330

Yin Z, Huang Y, Yang H, et al. Flexible electronics manufacturing technology and equipment. Sci China Tech Sci, 2022, 65: 1940–1956

Liu Q, Chen J, Yang H, et al. Accurate stereo-vision-based flying droplet volume measurement method. IEEE Trans Instrum Meas, 2021, 71: 1–16

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant No. 51975236), the National Key Research and Development Program of China (Grant No. 2018YFA0703203), and Innovation Project of Optics Valley Laboratory (Grant No. OVL2021BG007).

Rights and permissions

About this article

Cite this article

Xiong, J., Chen, J., Wang, Y. et al. Planning method of droplet fusion scheduling based on mixed-integer programming. Sci. China Technol. Sci. 67, 157–171 (2024). https://doi.org/10.1007/s11431-023-2505-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-023-2505-4