Abstract

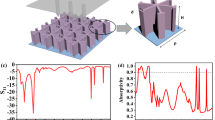

Microwave absorbers (MAs) with broadband and strong microwave absorption capacities are urgently required to meet the demands of complex electromagnetic (EM) environments. Herein, a novel labyrinth multiresonant metastructure composed of a polyether-ether-ketone/flaky carbonyl iron (PEEK/CIP) magnetic composite was proposed and fabricated via 3D printing technology. A complex multiresonant cavity design was introduced, and the resonant loss area was significantly improved. Both broadband and high-efficiency microwave absorption performances were achieved. The multilayer labyrinth multiresonant metastructure was designed with gradient impedance. The effects of structural parameters on the absorbing properties were investigated and optimized. Experiments and simulations demonstrated the effectiveness of the design strategy. The designed metastructure with a 10 mm thickness exhibited a −10 dB absorption bandwidth at a frequency of 3.78–40 GHz and an absorption bandwidth below −15 dB at 7.5–36.5 GHz. Moreover, an excellent wide-angle absorption performance was observed for different polarization states, including transverse electric (TE) and transverse magnetic (TM) modes. The combination of a complex multiresonant metastructure design and 3D printing fabrication provides a facile route to considerably extend the absorption bandwidth and strength of electromagnetic absorbers. This work is expected to provide a promising strategy for further enhancing microwave absorption performance, and the designed metastructure possesses great application potential in stealth and electromagnetic compatibility technologies.

Similar content being viewed by others

References

Kumar R, Sahoo S, Joanni E, et al. Recent progress on carbon-based composite materials for microwave electromagnetic interference shielding. Carbon, 2021, 177: 304–331

Amiri M, Tofigh F, Shariati N, et al. Review on metamaterial perfect absorbers and their applications to IoT. IEEE Internet Things J, 2021, 8: 4105–4131

Jayalakshmi C G, Inamdar A, Anand A, et al. Polymer matrix composites as broadband radar absorbing structures for stealth aircrafts. J Appl Polym Sci, 2018, 136: 47241

Ahmad H, Tariq A, Shehzad A, et al. Stealth technology: Methods and composite materials—A review. Polym Compos, 2019, 40: 4457–4472

Chen Y, Fu X, Liu L, et al. Millimeter wave absorbing property of flexible graphene/acrylonitrile-butadiene rubber composite in 5G frequency band. Polym-Plasts Tech Mater, 2019, 58: 903–914

Green M, Chen X. Recent progress of nanomaterials for microwave absorption. J Materiomics, 2019, 5: 503–541

Fan Q, Yang X, Lei H, et al. Gradient nanocomposite with metas-tructure design for broadband radar absorption. Compos Part A-Appl Sci Manufact, 2020, 129: 105698

Sun X, He J, Li G, et al. Laminated magnetic graphene with enhanced electromagnetic wave absorption properties. J Mater Chem C, 2013, 1: 765–777

Rozanov K N. Ultimate thickness to bandwidth ratio of radar absorbers. IEEE Trans Antennas Propagat, 2000, 48: 1230–1234

Fan Q, Huang Y, Chen M, et al. Integrated design of component and configuration for a flexible and ultrabroadband radar absorbing composite. Compos Sci Tech, 2019, 176: 81–89

Huang Y, Song W L, Wang C, et al. Multi-scale design of electro-magnetic composite metamaterials for broadband microwave absorption. Compos Sci Tech, 2018, 162: 206–214

Li N, Huang G W, Li Y Q, et al. Enhanced microwave absorption performance of coated carbon nanotubes by optimizing the Fe3O4 nanocoating structure. ACS Appl Mater Inter, 2017, 9: 2973–2983

Qing Y, Min D, Zhou Y, et al. Graphene nanosheet- and flake car-bonyl iron particle-filled epoxy-silicone composites as thin-thickness and wide-bandwidth microwave absorber. Carbon, 2015, 86: 98–107

Zhang B S, Feng Y, Xiong H, et al. Microwave-absorbing properties of de-aggregated flake-shaped carbonyl-iron particle composites at 218 GHz. IEEE Trans Magn, 2006, 42: 1778–1781

Wen F, Zuo W, Yi H, et al. Microwave-absorbing properties of shape-optimized carbonyl iron particles with maximum microwave permeability. Physica B-Condensed Matter, 2009, 404: 3567–3570

Zhou Y, Zhou W, Li R, et al. Enhanced antioxidation and electromagnetic properties of Co-coated flaky carbonyl iron particles prepared by electroless plating. J Alloys Compd, 2015, 637: 10–15

Acher O, Dubourg S. Generalization of Snoek’s law to ferromagnetic films and composites. Phys Rev B, 2008, 77: 104440

Zhou Q, Yin X, Ye F, et al. A novel two-layer periodic stepped structure for effective broadband radar electromagnetic absorption. Mater Des, 2017, 123: 46–53

Li W, Wu T, Wang W, et al. Broadband patterned magnetic microwave absorber. J Appl Phys, 2014, 116: 044110

Yang D, Yin Y, Zhang Z, et al. Wide-angle microwave absorption properties of multilayer metamaterial fabricated by 3D printing. Mater Lett, 2020, 281: 128571

Duan Y, Liang Q, Yang Z, et al. A wide-angle broadband electro-magnetic absorbing metastructure using 3D printing technology. Mater Des, 2021, 208: 109900

Park M J, Choi J H, Kim S S. Wide bandwidth pyramidal absorbers of granular ferrite and carbonyl iron powders. IEEE Trans Magn, 2000, 36: 3272–3274

Liu T, Xu Y, Zheng D, et al. Fabrication and absorbing property of the tower-like absorber based on 3D printing process. Physica B-Condensed Matter, 2019, 553: 88–95

Johansson M, Holloway C L, Kuester E F. Effective electromagnetic properties of honeycomb composites, and hollow-pyramidal and alternating-wedge absorbers. IEEE Trans Antennas Propagat, 2005, 53: 728–736

Luo H, Chen F, Wang X, et al. A novel two-layer honeycomb sandwich structure absorber with high-performance microwave absorption. Compos Part A-Appl Sci Manufact, 2019, 119: 1–7

He F, Zhao Y, Si K, et al. Multisection step-impedance modeling and analysis of broadband microwave honeycomb absorbing structures. J Phys D-Appl Phys, 2021, 54: 015501

Huang Y, Yuan X, Chen M, et al. Ultrathin flexible carbon fiber reinforced hierarchical metastructure for broadband microwave absorption with nano lossy composite and multiscale optimization. ACS Appl Mater Inter, 2018, 10: 44731–44740

Huang Y, Yuan X, Wang C, et al. Flexible thin broadband microwave absorber based on a pyramidal periodic structure of lossy composite. Opt Lett, 2018, 43: 2764–2767

Joseph P J, Tyson A D, Burnside W D. An absorber tip diffraction coefficient. IEEE Trans Electromagn Compat, 1994, 36: 372–379

Daminabo S C, Goel S, Grammatikos S A, et al. Fused deposition modeling-based additive manufacturing (3D printing): Techniques for polymer material systems. Mater Today Chem, 2020, 16: 100248

Ngo T D, Kashani A, Imbalzano G, et al. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos Part B-Eng, 2018, 143: 172–196

Postiglione G, Natale G, Griffini G, et al. Conductive 3D micro-structures by direct 3D printing of polymer/carbon nanotube nano-composites via liquid deposition modeling. Compos Part A-Appl Sci Manufact, 2015, 76: 110–114

Penumakala P K, Santo J, Thomas A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos Part B-Eng, 2020, 201: 108336

Mizukami K, Kawaguchi T, Ogi K, et al. Three-dimensional printing of locally resonant carbon-fiber composite metastructures for attenuation of broadband vibration. Composit Struct, 2021, 255: 112949

Hu C, Dong J, Luo J, et al. 3D printing of chiral carbon fiber reinforced polylactic acid composites with negative Poisson’s ratios. Compos Part B-Eng, 2020, 201: 108400

Mandala R, Bannoth A P, Akella S, et al. A short review on fused deposition modeling 3D printing of bio-based polymer nanocompo-sites. J Appl Polym Sci, 2022, 139: 51904

Azarov A V, Antonov F K, Golubev M V, et al. Composite 3D printing for the small size unmanned aerial vehicle structure. Compos Part B-Eng, 2019, 169: 157–163

Hsissou R, Seghiri R, Benzekri Z, et al. Polymer composite materials: A comprehensive review. Composit Struct, 2021, 262: 113640

Rinaldi M, Ferrara M, Pigliaru L, et al. Additive manufacturing of polyether ether ketone-based composites for space application: A mini-review. CEAS Space J, 2021, 15: 77–87

Chen P, Wang H, Su J, et al. Recent advances on high-performance polyaryletherketone materials for additive manufacturing. Adv Mater, 2022, 34: 2200750

Zanjanijam A R, Major I, Lyons J G, et al. Fused filament fabrication of PEEK: A review of process-structure-property relationships. Polymers, 2020, 12: 1665

Dua R, Rashad Z, Spears J, et al. Applications of3D-printed peek via fused filament fabrication: A systematic review. Polymers, 2021, 13: 4046

Apeldorn T, Keilholz C, Wolff-Fabris F, et al. Dielectric properties of highly filled thermoplastics for printed circuit boards. J Appl Polym Sci, 2013, 128: 3758–3770

Liu S L, Bian J. Low dielectric loss LNT/PEEK composites with high mechanical strength and dielectric thermal stability. Int J Appl Ceram Technol, 2020, 17: 1341–1347

Kim S S, Jo S B, Gueon K I, et al. Complex permeability and permittivity and microwave absorption of ferrite-rubber composite at X-band frequencies. IEEE Trans Magn, 1991, 27: 5462–5464

Liu C, Qiao J, Zhang X, et al. Noncovalent self-assembly of a minuscule amount of nickel porphyrin on carbon nanotube for high-performance electromagnetic wave absorbing. Compos Part A-Appl Sci Manufact, 2023, 164: 107281

Zhang X, Tian X, Liu C, et al. MnCo-MOF-74 derived porous MnO/Co/C heterogeneous nanocomposites for high-efficiency electro-magnetic wave absorption. Carbon, 2022, 194: 257–266

Zhang R, Wu N, Pan F, et al. Scalable manufacturing of light, multifunctional cellulose nanofiber aerogel sphere with tunable micro-structure for microwave absorption. Carbon, 2023, 203: 181–190

Liu P, Zhang Y, Yan J, et al. Synthesis of lightweight N-doped gra-phene foams with open reticular structure for high-efficiency electromagnetic wave absorption. Chem Eng J, 2019, 368: 285–298

Liu X, Chen Y, Cui X, et al. Flexible nanocomposites with enhanced microwave absorption properties based on Fe3O4/SiO2 nanorods and polyvinylidene fluoride. J Mater Chem A, 2015, 3: 12197–12204

Yin L, Tian X, Shang Z, et al. Ultra-broadband metamaterial absorber with graphene composites fabricated by 3D printing. Mater Lett, 2019, 239: 132–135

Zhang T, Duan Y, Liu J, et al. Polarization insensitive hierarchical metamaterial for broadband microwave absorption with multi-scale optimization and integrated design. Compos Sci Tech, 2022, 228: 109643

Cho H S, Kim S S. Design of grid-type microwave absorbers with high-permittivity composites of Ag-coated Ni-Zn ferrite particles. J Appl Phys, 2015, 117: 17A311

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the Fundamental Research Funds for the Central Universities (Grant No. xzd012021041). We would like to thank the Analytical & Testing Center of Xi’an Jiaotong University for SEM analysis.

Rights and permissions

About this article

Cite this article

Duan, Y., Liang, Q., Yang, Z. et al. 3D printed labyrinth multiresonant composite metastructure for broadband and strong microwave absorption. Sci. China Technol. Sci. 66, 3574–3584 (2023). https://doi.org/10.1007/s11431-023-2438-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-023-2438-1