Abstract

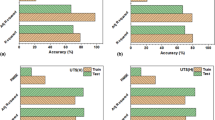

Pipeline transportation is one of the most economical ways to transport crude oil and natural gas over long distances. High toughness is one of the important qualities of pipeline steel to ensure safe transportation, wherein a key factor characterizing toughness is Charpy impact toughness (CIT). In this work, according to the production line data provided by a steel mill and the experimental data collected in literature, two machine learning model construction strategies were proposed. One was based solely on the production line dataset, and the other was based on the production line dataset together with the literature dataset. In these two strategies, the random forest model displayed the best prediction results, the accuracy of strategy I was 0.58, and the accuracy of strategy II was 0.90, wherein literature data effectively improved the CIT prediction accuracy. Finally, an optimized CIT model based on machine learning algorithms was established. The proposed strategy of literature data-assisted production line data provides a new perspective for optimizing and predicting the performance of traditional structural materials.

Similar content being viewed by others

References

Shanmugam S, Ramisetti N K, Misra R D K, et al. Microstructure and high strength-toughness combination of a new 700 MPa Nb-micro-alloyed pipeline steel. Mater Sci Eng-A, 2008, 478: 26–37

Bott I S, De Souza L F G, Teixeira J C G, et al. High-strength steel development for pipelines: A Brazilian perspective. Metall Mat Trans A, 2005, 36: 443–454

Wang C, Wang M, Shi J, et al. Microstructural characterization and its effect on strength of low carbon martensitic steel. J Mater Sci Technol, 2007, 23: 659

Kim H, Ha Y, Kwon K H, et al. Interpretation of cryogenic-temperature Charpy impact toughness by microstructural evolution of dynamically compressed specimens in austenitic 0.4C-(22–26)Mn steels. Acta Mater, 2015, 87: 332–343

Liu Y, Guo B, Zou X, et al. Machine learning assisted materials design and discovery for rechargeable batteries. Energy Storage Mater, 2020, 31: 434–450

Liu Y, Zhao T, Ju W, et al. Materials discovery and design using machine learning. J Materiomics, 2017, 3: 159–177

Zhou X Y, Zhu J H, Wu Y, et al. Machine learning assisted design of FeCoNiCrMn high-entropy alloys with ultra-low hydrogen diffusion coefficients. Acta Mater, 2022, 224: 117535

Fu H, Zhang H, Wang C, et al. Recent progress in the machine learning-assisted rational design of alloys. Int J Miner Metall Mater, 2022, 29: 635–644

Deng Z, Yin H, Jiang X, et al. Machine-learning-assisted prediction of the mechanical properties of Cu−Al alloy. Int J Miner Metall Mater, 2020, 27: 362–373

Pan G, Wang F, Shang C, et al. Advances in machine learning- and artificial intelligence-assisted material design of steels. Int J Miner Metall Mater, 2023, 30: 1003–1024

Zhang H, Fu H, Shen Y, et al. Rapid design of secondary deformation-aging parameters for ultra-low Co content Cu−Ni−Co−Si−X alloy via Bayesian optimization machine learning. Int J Miner Metall Mater, 2022, 29: 1197–1205

Lu Q, Liu S, Li W, et al. Combination of thermodynamic knowledge and multilayer feedforward neural networks for accurate prediction of MS temperature in steels. Mater Des, 2020, 192: 108696

Liu Y, Zou X, Ma S, et al. Feature selection method reducing correlations among features by embedding domain knowledge. Acta Mater, 2022, 238: 118195

Chen Y, Wang S, Xiong J, et al. Identifying facile material descriptors for Charpy impact toughness in low-alloy steel via machine learning. J Mater Sci Tech, 2023, 132: 213–222

Fürnkranz J, Gamberger D, Lavrač N. Foundations of Rule Learning. Berlin: Springer Science & Business Media, 2012

Jiang X, Jia B, Zhang G, et al. A strategy combining machine learning and multiscale calculation to predict tensile strength for pearlitic steel wires with industrial data. Scripta Mater, 2020, 186: 272–277

Matrosov Y I, Bagmet O A, Nosochenko A O. Development of modern heavy plate steels for pipelines. Trans Tech Publ, 2007, 539–543: 4756–4761

Kang M, Kim H, Lee S, et al. Effects of dynamic strain hardening exponent on abnormal cleavage fracture occurring during drop weight tear test of API X70 and X80 linepipe steels. Metall Mat Trans A, 2014, 45: 682–697

Wu Q, Zhang Z, Liu Y. Strain aging behavior of microalloyed low carbon seamless pipeline steel. ISIJ Int, 2016, 56: 126–131

Wu Q, Zhang Z, Liu Y, et al. Strain aging behaviour of Cu-containing microalloyed low carbon seamless pipeline steel. Mater Sci Tech, 2017, 33: 72–76

Zuo X, Zhou Z. Study of pipeline steels with acicular ferrite microstructure and ferrite-bainite dual-phase microstructure. Mat Res, 2015, 18: 36–41

Sha Q, Li D. Microstructure, mechanical properties and hydrogen induced cracking susceptibility of X80 pipeline steel with reduced Mn content. Mater Sci Eng-A, 2013, 585: 214–221

Zha C, Jiang Z, Wang W, et al. Research and development of heavy wall X80 transmission pipeline steel with high deformation characteristics for polar environments at Shougang Steel. Amer Soc Mech Eng, 2012, 45158: 249–255

Johnson J, Hudson M, Takahashi N, et al. Specification and manufacturing of pipes for the x100 operational trial. Int Pipeline Conf, 2008, 48593: 453–461

Seo D H, Yoo J Y, Song W H, et al. Development of X100 linepipe steel with high deformation capacity. Int Pipeline Conf, 2008, 48593: 585–592

Hillenbrand H G, Liessem A, Grimpe F, et al. Manufacturing of X100 pipes for the TAP Project. Int Pipeline Conf, 2006, 42630: 261–267

Yao S J, Du L X, Wang G D. Microstructure of Nb-bearing pipeline steel with improved property applying ultrafast cooling process. Steel Res Int, 2014, 85: 60–66

Beden S. Reliability of the installation and operation of pipeline systems. Basrah J Eng Sci, 2016, 16: 108–118

Yakubtsov I A, Poruks P, Boyd J D. Microstructure and mechanical properties of bainitic low carbon high strength plate steels. Mater Sci Eng-A, 2008, 480: 109–116

You Y, Shang C, Wenjin N, et al. Investigation on the microstructure and toughness of coarse grained heat affected zone in X-100 multiphase pipeline steel with high Nb content. Mater Sci Eng-A, 2012, 558: 692–701

Zhao M C, Yang K, Shan Y. The effects of thermo-mechanical control process on microstructures and mechanical properties of a commercial pipeline steel. Mater Sci Eng-A, 2002, 335: 14–20

Zhang J, Sun W, Sun H. Mechanical properties and microstructure of X120 grade high strength pipeline steel. J Iron Steel Res Int, 2010, 17: 63–67

Shin S Y, Woo K J, Hwang B, et al. Fracture-toughness analysis in transition-temperature region of Three American Petroleum Institute X70 and X80 pipeline steels. Metall Mat Trans A, 2009, 40: 867–876

Guo A, Misra R D K, Xu J, et al. Ultrahigh strength and low yield ratio of niobium-microalloyed 900 MPa pipeline steel with nano/ultrafine bainitic lath. Mater Sci Eng-A, 2010, 527: 3886–3892

Li J, Gao X, Du L, et al. Relationship between microstructure and hydrogen induced cracking behavior in a low alloy pipeline steel. J Mater Sci Tech, 2017, 33: 1504–1512

Shin S Y, Hong S, Bae J H, et al. Separation phenomenon occurring during the Charpy impact test of API X80 pipeline steels. Metall Mat Trans A, 2009, 40: 2333–2349

Hwang B, Kim Y G, Lee S, et al. Effective grain size and charpy impact properties of high-toughness X70 pipeline steels. Metall Mat Trans A, 2005, 36: 2107–2114

Li R, Zuo X, Hu Y, et al. Microstructure and properties of pipeline steel with a ferrite/martensite dual-phase microstructure. Mater Charact, 2011, 62: 801–806

Wang W, Shan Y, Yang K. Study of high strength pipeline steels with different microstructures. Mater Sci Eng-A, 2009, 502: 38–44

Wang W, Yan W, Zhu L, et al. Relation among rolling parameters, microstructures and mechanical properties in an acicular ferrite pipeline steel. Mater Des, 2009, 30: 3436–3443

Sung H K, Lee S, Shin S Y. Effects of start and finish cooling temperatures on microstructure and mechanical properties of low-carbon high-strength and low-yield ratio bainitic steels. Metall Mat Trans A, 2014, 45: 2004–2013

Yoo J, Jo M C, Bian J, et al. Effects of Nb or (Nb+Mo) alloying on Charpy impact, bending, and delayed fracture properties in 1.9-GPa-grade press hardening steels. Mater Charact, 2021, 176: 111133

Siahpour P, Miresmaeili R, Sabour Rouhaghdam A. Temperature effect of hot rolling process on microstructure, strength and fracture toughness of X65 pipeline steel. Trans Ind Inst Met, 2018, 71: 1531–1541

Zuo X, Li R. Research of strain aging in pipeline steel with a ferrite/martensite dual-phase microstructure. Steel Res int, 2015, 86: 163–168

Cheng S, Zhang X, Zhang J, et al. Effect of coiling temperature on microstructure and properties of X100 pipeline steel. Mater Sci Eng-A, 2016, 666: 156–164

Shin S Y. Effects of microstructure on tensile, charpy impact, and crack tip opening displacement properties of two API X80 pipeline steels. Metall Mat Trans A, 2013, 44: 2613–2624

Han S Y, Shin S Y, Seo C H, et al. Effects of Mo, Cr, and V additions on tensile and Charpy impact properties of API X80 pipeline steels. Metall Mat Trans A, 2009, 40: 1851–1862

Shin S Y, Gong G, Kim S, et al. Analysis of fracture toughness in the transition temperature region of API X70 pipeline steels rolled in two-phase region. Metall Mater Trans A, 2007, 38: 1012–1021

Hwang B, Lee C G, Kim S J. Low-temperature toughening mechanism in thermomechanically processed high-strength low-alloy steels. Metall Mat Trans A, 2011, 42: 717–728

Shin S Y, Hwang B, Lee S, et al. Correlation of microstructure and charpy impact properties in API X70 and X80 line-pipe steels. Mater Sci Eng-A, 2007, 458: 281–289

Zhao W, Chen M, Chen S, et al. Static strain aging behavior of an X100 pipeline steel. Mater Sci Eng-A, 2012, 550: 418–422

Jordan M I, Mitchell T M. Machine learning: Trends, perspectives, and prospects. Science, 2015, 349: 255–260

Zhang T Y. An Introduction to Materials Informatics: The Elements of Machine Learning. Beijing: Science Press, 2022

Filliben J J. The probability plot correlation coefficient test for normality. Technometrics, 1975, 17: 111–117

Chai T, Draxler R R. Root mean square error (RMSE) or mean absolute error (MAE)?—Arguments against avoiding RMSE in the literature. 2014, doi: https://doi.org/10.5194/gmdd-7-1525-2014

Romanski P, Kotthoff L, Kotthoff M L. Package ‘FSelector’. 2013

Xue D, Xue D, Yuan R, et al. An informatics approach to transformation temperatures of NiTi-based shape memory alloys. Acta Mater, 2017, 125: 532–541

Diao Y, Yan L, Gao K. A strategy assisted machine learning to process multi-objective optimization for improving mechanical properties of carbon steels. J Mater Sci Tech, 2022, 109: 86–93

Liu Y, Niu C, Wang Z, et al. Machine learning in materials genome initiative: A review. J Mater Sci Tech, 2020, 57: 113–122

Wang Y, Wagner N, Rondinelli J M. Symbolic regression in materials science. MRS Commun, 2019, 9: 793–805

Koza J R. Genetic programming as a means for programming computers by natural selection. Stat Comput, 1994, 4: 87–112

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 52122408, 51901013, 52071023), H.H. Wu also thanks the financial support from the Fundamental Research Funds for the Central Universities (University of Science and Technology Beijing) (Grant Nos. FRF-TP-2021-04C1, and 06500135). The computing work is supported by USTB MatCom of Beijing Advanced Innovation Center for Materials Genome Engineering.

Supporting Information

The supporting information is available online at https://tech.scichina.com and https://link.springer.com. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

Rights and permissions

About this article

Cite this article

Shang, C., Wang, C., Wu, H. et al. Improved data-driven performance of Charpy impact toughness via literature-assisted production data in pipeline steel. Sci. China Technol. Sci. 66, 2069–2079 (2023). https://doi.org/10.1007/s11431-023-2372-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-023-2372-x