Abstract

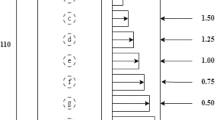

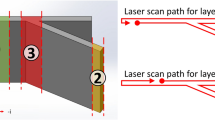

As an additive manufacturing technique, the laser-aided direct energy deposition (L-DED) method has been widely used for component repair (also called laser repair). With significant differences from traditional manufacturing techniques, the laser repair process has the characteristics of point-by-point deposition and has a high-temperature gradient in the repair area, resulting in the formation of heterogeneous thermal deformation and residual stress after cooling. High stress may lead to the appearance of cracks in the repair area and may seriously influence the bearing capacity of the repaired parts. Therefore, the characterization of the temperature and deformation fields of the components during laser repair is important for the analysis of the mechanism of damage evolution in the repair area, optimization of the process parameters, and improvement of the mechanical properties of the repaired components. Because of the demand for the simultaneous measurement of the temperature and deformation fields, using a multispectral camera and a self-designed three-peak filter, a temperature-deformation field measurement technique was developed and applied to in situ monitoring during the L-DED manufacturing process. In the actual measurement process, the synchronous measurement of the temperature field of the laser molten pool and the deformation field of the side surface of the repaired component were realized using the images of multiple channels in the multispectral camera. The experimental results verify that a three-peak filter can effectively eliminate the influences of glare and overexposure on the recorded multispectral images. Moreover, the amplitude of the displacement field and the temperature gradient of the repaired component will increase with the increase in laser power, which may affect the final molding of the repaired component. This work extends the function of the multispectral camera to measure the temperature and deformation fields and provides a new measurement method for further optimizing the process parameters of laser repair.

Similar content being viewed by others

References

DebRoy T, Mukherjee T, Wei H L, et al. Metallurgy, mechanistic models and machine learning in metal printing. Nat Rev Mater, 2021, 6: 48–68

Svetlizky D, Das M, Zheng B, et al. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater Today, 2021, 49: 271–295

Svetlizky D, Zheng B, Vyatskikh A, et al. Laser-based directed energy deposition (DED-LB) of advanced materials. Mater Sci Eng-A, 2022, 840: 142967

He W, Shi W, Li J, et al. In-situ monitoring and deformation characterization by optical techniques; part I: Laser-aided direct metal deposition for additive manufacturing. Optics Lasers Eng, 2019, 122: 74–88

Feng W, Mao Z, Yang Y, et al. Online defect detection method and system based on similarity of the temperature field in the melt pool. Addit Manuf, 2022, 54: 102760

Das T, Mukherjee M, Chatterjee D, et al. A comparative evaluation of the microstructural characteristics of L-DED and W-DED processed 316L stainless steel. CIRP J Manuf Sci Tech, 2023, 40: 114–128

Jeong S G, Ahn S Y, Kim E S, et al. Effect of substrate yield strength and grain size on the residual stress of direct energy deposition additive manufacturing measured by neutron diffraction. Mater Sci Eng-A, 2022, 851: 143632

Zhang J S, Yue M K, Wang J Y, et al. Improved monochromatic pyrometry for synchronous measurement of full-field temperature and deformation. Sci China Tech Sci, 2021, 64: 2033–2046

Guo X, Yuan Y, Suo T, et al. A novel temperature-strain synchronous measurement method. Optics Lasers Eng, 2021, 147: 106723

Cholewa N, Summers P T, Feih S, et al. A technique for coupled thermomechanical response measurement using infrared thermography and digital image correlation (TDIC). Exp Mech, 2016, 56: 145–164

Ushiki T, Imazawa R, Murakami H, et al. Expanded two-color thermography considering temperature-dependent emissivity of tungsten for ITER divertor infrared thermography. Fusion Eng Des, 2021, 168: 112665

Seidt J D, Kuokkala V T, Smith J L, et al. Synchronous full-field strain and temperature measurement in tensile tests at low, intermediate and high strain rates. Exp Mech, 2017, 57: 219–229

Su H, Fang X, Qu Z, et al. Synchronous full-field measurement of temperature and deformation of C/SiC composite subjected to flame heating at high temperature. Exp Mech, 2016, 56: 659–671

Yue M, Wang J, Zhang J, et al. Color crosstalk correction for synchronous measurement of full-field temperature and deformation. Optics Lasers Eng, 2022, 150: 106878

Tang Y, Yue M, Fang X, et al. Synchronous full-field measurement of temperature and deformation based on separated radiation and reflected light. Optics Lasers Eng, 2019, 116: 94–102

Tang Y, Zhang J, Yue M, et al. High-frequency flashing oflight source for synchronous measurement of temperature and deformation at elevated temperature. Optics Lasers Eng, 2021, 137: 106361

Shi W, Li Y, Chen R, et al. Research on synchronous measurement technique of temperature and deformation fields using multispectral camera with bilateral telecentric lens. Theor Appl Mech Lett, 2022, 12: 100345

Nishioka T, Wakabayashi M, Fujimoto T. An intelligent hybrid measurement method for steady temperature field. Exp Mech, 2010, 50: 1149–1155

Shi W, Zhang C, Xie H. Online deformation measurement of laser repair substrate based on orthogonal sampling Moiré. Appl Sci, 2022, 12: 5469

Yu L, Pan B. Overview of high-temperature deformation measurement using digital image correlation. Exp Mech, 2021, 61: 1121–1142

Zhao J, Liu Z, Guo B. Three-dimensional digital image correlation method based on a light field camera. Optics Lasers Eng, 2019, 116: 19–25

Zhang J, Shang Y, Li X, et al. A novel technique for full-field deformation and temperature measurement by ultraviolet imaging: Experimental design and preliminary results. Coatings, 2021, 11: 641

Sutton M A. Computer vision-based, noncontacting deformation measurements in mechanics: A generational transformation. Appl Mech Rev, 2013, 65: 050802

Wang J, Tang Y, Zhang J, et al. Convolutional neural network-based image denoising for synchronous measurement of temperature and deformation at elevated temperature. Optik, 2021, 241: 166977

Tang Y, Zhang J, Yue M, et al. Deep learning-based super-resolution images for synchronous measurement of temperature and deformation at elevated temperature. Optik, 2021, 226: 165764

Wu L, Zhu J, Xie H, et al. Single-lens 3D digital image correlation system based on a bilateral telecentric lens and a bi-prism: Systematic error analysis and correction. Optics Lasers Eng, 2016, 87: 129–138

Pan B, Yu L, Wu D. High-accuracy 2D digital image correlation measurements with bilateral telecentric lenses: Error analysis and experimental verification. Exp Mech, 2013, 53: 1719–1733

Wu L, Zhu J, Xie H. Single-lens 3D digital image correlation system based on a bilateral telecentric lens and a bi-prism: Validation and application. Appl Opt, 2015, 54: 7842–7850

Bose S. Plancks gesetz und lichtquantenhypothese. Z Physik, 1924, 26: 178–181

Das R. Wavelength- and frequency-dependent formulations of Wien’s displacement law. J Chem Educ, 2015, 92: 1130–1134

Hu A, Tan W, Shu Q, et al. A method for improving temperature measurement accuracy based on CCD color. J Comput Electron Inform Manag, 2018, 5: 1–9

Huang Y, Yan Y, Riley G. Vision-based measurement of temperature distribution in a 500-kW model furnace using the two-colour method. Measurement, 2000, 28: 175–183

Li Y, Zhang Q, Xie H. Fabrication of heat-resistant grids and their application to deformation measurements using a sampling Moiré method. Meas Sci Technol, 2021, 32: 105008

Chen R, Zhang Q, He W, et al. Orthogonal sampling Moiré method and its application in microscale deformation field measurement. Optics Lasers Eng, 2022, 149: 106811–229

Wang Q, Ri S, Tsuda H, et al. Two-dimensional Moiré phase analysis for accurate strain distribution measurement and application in crack prediction. Opt Express, 2017, 25: 13465–13480

Ri S, Fujigaki M, Morimoto Y. Sampling Moiré method for accurate small deformation distribution measurement. Exp Mech, 2010, 50: 501–508

Morimoto Y, Fujigaki M. Accuracy of sampling Moiré method. In: ICEM 2008: International Conference on Experimental Mechanics. Nanjing, 2008. 737526

Lévesque L. Nyquist sampling theorem: Understanding the illusion of a spinning wheel captured with a video camera. Phys Educ, 2014, 49: 697–705

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 12032013 and 11972209) and the National Key Research and Development Program of China (Grant No. 2017YFB1103900).

Rights and permissions

About this article

Cite this article

Shi, W., Zhang, C., Chen, R. et al. Multiphysics coupling in situ measurement method for laser repair of the Inconel 718 alloy structure. Sci. China Technol. Sci. 66, 2986–2995 (2023). https://doi.org/10.1007/s11431-022-2419-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2419-7