Abstract

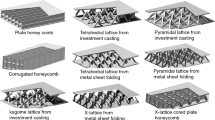

A previous study showed that the thermal performance of the X-lattice cored corrugated honeycomb (XCCH) is better than that of most other periodic cellular materials (PCMs). To further improve the thermal performance of the XCCH, the effects of different ripple amplitudes (i.e., a = 0.5, 0.7 and 1.0) on the characteristics of the flow and heat transfer are numerically investigated by thorough comparisons. In terms of the flow characteristics, with the increase of ripple amplitude, the vortex interaction in the channel becomes stronger, which results in evident increase of kinetic energy of turbulence at the boundary of vortex and reduction in the turbulent kinetic energy dissipation. As far as the heat transfer is concerned, within the Reynolds number range of 3696–7436, the heat transfer increases with the increase of ripple amplitude. The overall Nusselt number of the XCCH with a = 1.0 is 15.7% higher than that with a = 0.5. Within the corresponding range of pumping power, the thermal performance of the XCCH with a = 1.0 is up to 7% higher than that with a = 0.5 at relatively higher Reynolds numbers.

Similar content being viewed by others

References

Hegab H A. Design for additive manufacturing of composite materials and potential alloys: A review. Manufact Rev, 2016, 3: 11

Ferrari L, Barbato M, Esser B, et al. Sandwich structured ceramic matrix composites with periodic cellular ceramic cores: An active cooled thermal protection for space vehicles. Composite Struct, 2016, 154: 61–68

Song J, Sun B. Coupled numerical simulation of combustion and regenerative cooling in LOX/Methane rocket engines. Appl Thermal Eng, 2016, 106: 762–773

Yan H B, Mew T, Lee M G, et al. Thermofluidic characteristics of a porous ventilated brake disk. J Heat Transfer, 2015, 137: 022601

Yan H B, Zhang Q C, Lu T J. An X-type lattice cored ventilated brake disc with enhanced cooling performance. Int J Heat Mass Transfer, 2015, 80: 458–468

Xu L, Chen H, Xi L, et al. Flow and heat transfer characteristics of a staggered array of Kagome lattice structures in rectangular channels. Heat Mass Transfer, 2022, 58: 41–64

Narato P, Wae-hayee M, Kaewchoothong N, et al. Heat transfer enhancement and flow characteristics in a rectangular channel having inclined pin arrays mounted on the endwall surface. Int Commun Heat Mass Transfer, 2021, 122: 105162

Nouri-Borujerdi A, Nakhchi M E. Prediction of local shear stress and heat transfer between internal rotating cylinder and longitudinal cavities on stationary cylinder with various shapes. Int J Thermal Sci, 2019, 138: 512–520

Chiras S, Mumm D R, Evans A G, et al. The structural performance of near-optimized truss core panels. Int J Solids Struct, 2002, 39: 4093–4115

Jobic Y, Kumar P, Topin F, et al. Transport properties of solid foams having circular strut cross section using pore scale numerical simulations. Heat Mass Transfer, 2018, 54: 2351–2370

Atkins M D, Kienhöfer F W, Kang K, et al. Cooling mechanisms in a rotating brake disc with a wire-woven-bulk diamond cellular core. J Thermal Sci Eng Appl, 2021, 13: 041006

Ma Y, Yan H, Hooman K, et al. Enhanced heat transfer in a pyramidal lattice sandwich panel by introducing pin-fins/protrusions/dimples. Int J Thermal Sci, 2020, 156: 106468

Wei K, Cheng X, Mo F, et al. Design and analysis of integrated thermal protection system based on lightweight C/SiC pyramidal lattice core sandwich panel. Mater Des, 2016, 111: 435–444

Wei K, Peng Y, Qu Z, et al. High temperature mechanical behaviors of lightweight ceramic corrugated core sandwich panel. Composite Struct, 2017, 176: 379–387

Wei K, He R, Cheng X, et al. Fabrication and heat transfer characteristics of C/SiC pyramidal core lattice sandwich panel. Appl Thermal Eng, 2015, 81: 10–17

Chaudhari A, Ekade P, Krishnan S. Experimental investigation of heat transfer and fluid flow in octet-truss lattice geometry. Int J Thermal Sci, 2019, 143: 64–75

Kang K J. Wire-woven cellular metals: The present and future. Prog Mater Sci, 2015, 69: 213–307

Wadley H. Fabrication and structural performance of periodic cellular metal sandwich structures. Compos Sci Tech, 2003, 63: 2331–2343

Yan H B, Zhang Q C, Lu T J, et al. A lightweight X-type metallic lattice in single-phase forced convection. Int J Heat Mass Transfer, 2015, 83: 273–283

Zhang Q C, Chen A P, Chen C Q, et al. Ultralight X-type lattice sandwich structure (II): Micromechanics modeling and finite element analysis. Sci China Ser E-Technol Sci, 2009, 52: 2670–2680

Kooistra G W, Wadley H N G. Lattice truss structures from expanded metal sheet. Mater Des, 2007, 28: 507–514

Kim T, Hodson H P, Lu T J. Contribution of vortex structures and flow separation to local and overall pressure and heat transfer characteristics in an ultralightweight lattice material. Int J Heat Mass Transfer, 2005, 48: 4243–4264

Kim T, Zhao C Y, Lu T J, et al. Convective heat dissipation with lattice-frame materials. Mech Mater, 2004, 36: 767–780

Hoffmann F. Heat Transfer Performance and Pressure Drop of Kagome Core Metal Truss Panels. Cambridge: University of Cambridge, 2002

Zhao L, Ryan S M, Ortega J K, et al. Experimental investigation of 3D woven Cu lattices for heat exchanger applications. Int J Heat Mass Transfer, 2016, 96: 296–311

Li J, Abdulghani Z R, Alghamdi M N, et al. Effect of twisted fins on the melting performance of PCM in a latent heat thermal energy storage system in vertical and horizontal orientations: Energy and exergy analysis. Appl Thermal Eng, 2023, 219: 119489

Wang X, Zhong Z, Zeng T, et al. Heat transfer property of C/SiC composite pyramidal lattice core sandwich structures. Composite Struct, 2022, 301: 116215

Chen J, Yan L, Yan H, et al. Thermo-structural performance and flow analysis of X-latticed honeycombs with plate or corrugated walls. J Therm Anal Calorim, 2023, 148: 3613–3629

Zhou J H, Chen X M, Li Q. Numerical study on two-phase boiling heat transfer performance of interrupted microchannel heat sinks. Sci China Tech Sci, 2022, 65: 679–692

Zhang J J, Chen Y W, Liu Y, et al. Experimental investigation on heat transfer characteristics of microcapsule phase change material suspension in array jet impingement. Sci China Tech Sci, 2022, 65: 1634–1645

Coleman H W, Steele W G. Experimentation, Validation, and Uncertainty Analysis for Engineers. 3rd ed. Hoboken: John Wiley & Sons Inc., 2009

Tian J, Kim T, Lu T J, et al. The effects of topology upon fluid-flow and heat-transfer within cellular copper structures. Int J Heat Mass Transfer, 2004, 47: 3171–3186

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant No. 51806176), and the Fundamental Research Funds for the Central Universities (Grant No. 30922010914).

Rights and permissions

About this article

Cite this article

Chen, J., Xie, G. & Yan, H. The effects of ripple amplitude on heat transfer and fluid flow of X-lattice corrugated honeycombs. Sci. China Technol. Sci. 66, 3412–3421 (2023). https://doi.org/10.1007/s11431-022-2378-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2378-2