Abstract

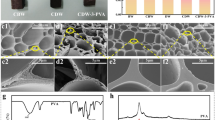

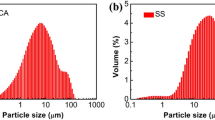

Latent heat thermal energy storage (LHTES) technology is gaining extensive attention due to its capability to balance supply and demand mismatch in solar energy utilization. However, phase change material as the core of storing latent heat still suffers from low thermal conductivity and poor shape stability, which severely restricts its practical application. Here, an eco-friendly strategy for achieving high-performance dual functional thermal and solar energy storage is proposed via turning wood processing waste into high-value hierarchical porous SiC ceramic-based composite phase change materials. The porosity of prepared porous SiC skeletons is highly adjustable from 59.4% to 90.2%, overcoming low porosity limitations of traditional wood materials and enabling tunable energy storage density for various applications. High thermal conductivity is achieved by benefiting from large grains and continuous skeletons with a value up to 37.93 and 1.87 W/(m K) for porosity of 59.4% and 90.2%, respectively. Excellent stabilities are demonstrated with only slight decreases of thermal conductivity and energy storage density over 1000 cycles and good anti-leakage properties are confirmed due to capillary adsorption forces induced by hierarchical pores. Benefiting from high thermal conductivity and high solar absorptance, fast and efficient solar thermal energy storage is successfully demonstrated. This work provides a new strategy for the high-value utilization of wood processing waste and efficient thermal/solar energy storage.

Similar content being viewed by others

References

Koçak B, Fernandez A I, Paksoy H. Review on sensible thermal energy storage for industrial solar applications and sustainability aspects. Sol Energy, 2020, 209: 135–169

Pereira da Cunha J, Eames P. Thermal energy storage for low and medium temperature applications using phase change materials—A review. Appl Energy, 2016, 177: 227–238

Chu S, Cui Y, Liu N. The path towards sustainable energy. Nat Mater, 2016, 16: 16–22

Song C, Liu X L, Xuan Y M, et al. Granular porous calcium carbonate particles for scalable and high-performance solar-driven thermochemical heat storage. Sci China Tech Sci, 2021, 64: 2142–2152

Kousksou T, Bruel P, Jamil A, et al. Energy storage: Applications and challenges. Sol Energy Mater Sol Cells, 2014, 120: 59–80

Kabir E, Kumar P, Kumar S, et al. Solar energy: Potential and future prospects. Renew Sustain Energy Rev, 2018, 82: 894–900

Aftab W, Khurram M, Jinming S, et al. Highly efficient solar-thermal storage coating based on phosphorene encapsulated phase change materials. Energy Storage Mater, 2020, 32: 199–207

Lu X, Liang B, Sheng X, et al. Enhanced thermal conductivity of polyurethane/wood powder composite phase change materials via incorporating low loading of graphene oxide nanosheets for solar thermal energy storage. Sol Energy Mater Sol Cells, 2020, 208: 110391

Xie T, Xu K D, Yang B L, et al. Effect of pore size and porosity distribution on radiation absorption and thermal performance of porous solar energy absorber. Sci China Tech Sci, 2019, 62: 2213–2225

Crespo A, Barreneche C, Ibarra M, et al. Latent thermal energy storage for solar process heat applications at medium-high temperatures—A review. Sol Energy, 2019, 192: 3–34

Liu X L, Song F Z, Xu Q, et al. The influence of pore size distribution on thermal conductivity, permeability, and phase change behavior of hierarchical porous materials. Sci China Tech Sci, 2021, 64: 2485–2494

Guene Lougou B, Shuai Y, Pan R M, et al. Radiative heat transfer and thermal characteristics of Fe-based oxides coated SiC and Alumina RPC structures as integrated solar thermochemical reactor. Sci China Tech Sci, 2018, 61: 1788–1801

Li T, Wu M, Wu S, et al. Highly conductive phase change composites enabled by vertically-aligned reticulated graphite nanoplatelets for high-temperature solar photo/electro-thermal energy conversion, harvesting and storage. Nano Energy, 2021, 89: 106338

Shi X, Zhao X, Wang F, et al. Improving overall heat transfer performance of parabolic trough solar receiver by helically convex absorber tube. Appl Thermal Eng, 2022, 213: 118690

Hu Y, He Y, Zhang Z, et al. Enhanced heat capacity of binary nitrate eutectic salt-silica nanofluid for solar energy storage. Sol Energy Mater Sol Cells, 2019, 192: 94–102

Alva G, Liu L, Huang X, et al. Thermal energy storage materials and systems for solar energy applications. Renew Sustain Energy Rev, 2017, 68: 693–706

Li Q, Liu Y, Guo S, et al. Solar energy storage in the rechargeable batteries. Nano Today, 2017, 16: 46–60

Chen K, Guo L J, Wang H. A review on thermal application of metal foam. Sci China Tech Sci, 2020, 63: 2469–2490

Du S, Li Z Y, He Y L, et al. Experimental and numerical analysis of the hydraulic and thermal performances of the gradually-varied porous volumetric solar receiver. Sci China Tech Sci, 2020, 63: 1224–1234

Ge Z, Wang L, Huang Y, et al. Latent heat of molten salt transport across graphite induced anisotropic interface. Sol Energy Mater Sol Cells, 2022, 236: 111496

Shi J, Qin M, Aftab W, et al. Flexible phase change materials for thermal energy storage. Energy Storage Mater, 2021, 41: 321–342

Tang Z, Gao H, Chen X, et al. Advanced multifunctional composite phase change materials based on photo-responsive materials. Nano Energy, 2021, 80: 105454

Gulfam R, Zhang P, Meng Z. Advanced thermal systems driven by paraffin-based phase change materials—A review. Appl Energy, 2019, 238: 582–611

Li X, Chen H, Liu L, et al. Development of granular expanded perlite/paraffin phase change material composites and prevention of leakage. Sol Energy, 2016, 137: 179–188

Qiu L, Yan K, Feng Y, et al. Bionic hierarchical porous aluminum nitride ceramic composite phase change material with excellent heat transfer and storage performance. Compos Commun, 2021, 27: 100892

Xie Y, Li W, Huang H, et al. Bio-based radish@PDA/PEG Sandwich composite with high efficiency solar thermal energy storage. ACS Sustain Chem Eng, 2020, 8: 8448–8457

Zhao Y, Jin L, Zou B, et al. Expanded graphite-Paraffin composite phase change materials: Effect of particle size on the composite structure and properties. Appl Thermal Eng, 2020, 171: 115015

Wang Q, Zhou D, Chen Y, et al. Characterization and effects of thermal cycling on the properties of paraffin/expanded graphite composites. Renew Energy, 2020, 147: 1131–1138

Chen G, Su Y, Jiang D, et al. An experimental and numerical investigation on a paraffin wax/graphene oxide/carbon nanotubes composite material for solar thermal storage applications. Appl Energy, 2020, 264: 114786

Myers Jr. P D, Alam T E, Kamal R, et al. Nitrate salts doped with CuO nanoparticles for thermal energy storage with improved heat transfer. Appl Energy, 2016, 165: 225–233

Han D, Lougou B G, Shuai Y, et al. Study of thermophysical properties of chloride salts doped with CuO nanoparticles for solar thermal energy storage. Sol Energy Mater Sol Cells, 2022, 234: 111432

Cao J, Ling Z, Lin X, et al. Flexible composite phase change material with enhanced thermophysical, dielectric, and mechanical properties for battery thermal management. J Energy Storage, 2022, 52: 104796

Liu C, Yu D, Kirk D W, et al. Porous silicon carbide derived from apple fruit with high electromagnetic absorption performance. J Mater Chem C, 2016, 4: 5349–5356

Lan X, Liang C, Wu M, et al. Facile synthesis of highly defected silicon carbide sheets for efficient absorption of electromagnetic waves. J Phys Chem C, 2018, 122: 18537–18544

Liang C, Wang Z. Eggplant-derived SiC aerogels with high-performance electromagnetic wave absorption and thermal insulation properties. Chem Eng J, 2019, 373: 598–605

Maity A, Kalita D, Kayal N, et al. Synthesis of biomorphic SiC ceramics from coir fibreboard preform. Ceramics Int, 2012, 38: 6873–6881

Luo Q, Liu X, Yao H, et al. Fast and stable solar/thermal energy storage via gradient SiC foam-based phase change composite. Int J Heat Mass Transfer, 2022, 194: 123012

Song Y, Xu Q, Liu X, et al. High-performance thermal energy storage and thermal management via starch-derived porous ceramics-based phase change devices. Int J Heat Mass Transfer, 2022, 197: 123337

Liu X, Song Y, Xu Q, et al. Nacre-like ceramics-based phase change composites for concurrent efficient solar-to-thermal conversion and rapid energy storage. Sol Energy Mater Sol Cells, 2021, 230: 111240

Luo Q, Liu X, Wang H, et al. Synergetic enhancement of heat storage density and heat transport ability of phase change materials inlaid in 3D hierarchical ceramics. Appl Energy, 2022, 306: 117995

Jana D C, Sundararajan G, Chattopadhyay K, et al. Effect of porosity on structure, Young’s modulus, and thermal conductivity of SiC foams by direct foaming and gelcasting. J Am Ceramic Soc, 2017, 100: 312–322

Sarikaya A, Dogan F. Effect of various pore formers on the microstructural development of tape-cast porous ceramics. Ceramics Int, 2013, 39: 403–413

Chabi S, Rocha V G, Garcıa-Tuñón E, et al. Ultralight, strong, three-dimensional SiC structures. ACS Nano, 2016, 10: 1871–1876

Zhou M, Lin T, Huang F, et al. Highly conductive porous graphene/ceramic composites for heat transfer and thermal energy storage. Adv Funct Mater, 2013, 23: 2263–2269

Fukahori R, Nomura T, Zhu C, et al. Macro-encapsulation of metallic phase change material using cylindrical-type ceramic containers for high-temperature thermal energy storage. Appl Energy, 2016, 170: 324–328

Trevisan S, Wang W, Laumert B. A high-temperature thermal stability and optical property study of inorganic coatings on ceramic particles for potential thermal energy storage applications. Sol Energy Mater Sol Cells, 2022, 239: 111679

Calderon N R, Martinez-Escandell M, Narciso J, et al. Manufacture of biomorphic SiC components with homogeneous properties from sawdust by reactive infiltration with liquid silicon. J Am Ceramic Soc, 2010, 93: 1003–1009

Herzog A, Vogt U, Kaczmarek O, et al. Porous SiC ceramics derived from tailored wood-based fiberboards. J Am Ceramic Soc, 2006, 89: 1499–1503

Pappacena K E, Faber K T, Wang H, et al. Thermal conductivity of porous silicon carbide derived from wood precursors. J Am Ceramic Soc, 2007, 90: 2855–2862

Xu Q, Liu X, Luo Q, et al. Bifunctional biomorphic SiC ceramics embedded molten salts for ultrafast thermal and solar energy storage. Mater Today Energy, 2021, 21: 100764

De Corato U, De Bari I, Viola E, et al. Assessing the main opportunities of integrated biorefining from agro-bioenergy co/by-products and agroindustrial residues into high-value added products associated to some emerging markets: A review. Renew Sustain Energy Rev, 2018, 88: 326–346

Bedoić R, Ćosić B, Duić N. Technical potential and geographic distribution of agricultural residues, co-products and by-products in the European Union. Sci Total Environ, 2019, 686: 568–579

Gregg J S, Jürgens J, Happel M K, et al. Valorization of bio-residuals in the food and forestry sectors in support of a circular bioeconomy: A review. J Cleaner Production, 2020, 267: 122093

Vishnu R, Prabhakaran K. Porous eco-ceramics of low thermal conductivity and high EMI shielding effectiveness from sawdust and sucrose by paste molding. Ceramics Int, 2021, 47: 34595–34610

Gómez-Martín A, Orihuela M P, Ramírez-Rico J, et al. Thermal conductivity of porous biomorphic SiC derived from wood precursors. Ceramics Int, 2016, 42: 16220–16229

Liu X, Chen M, Xu Q, et al. Bamboo derived SiC ceramics-phase change composites for efficient, rapid, and compact solar thermal energy storage. Sol Energy Mater Sol Cells, 2022, 240: 111726

Li R, Zhou Y, Duan X. A novel composite phase change material with paraffin wax in tailings porous ceramics. Appl Thermal Eng, 2019, 151: 115–123

Li Y, Li J, Deng Y, et al. Preparation of paraffin/porous TiO2 foams with enhanced thermal conductivity as PCM, by covering the TiO2 surface with a carbon layer. Appl Energy, 2016, 171: 37–45

Li Y, Li J, Feng W, et al. Design and preparation of the phase change materials paraffin/porous Al2O3@graphite foams with enhanced heat storage capacity and thermal conductivity. ACS Sustain Chem Eng, 2017, 5: 7594–7603

Li X, Wang H, Yang X, et al. Simple in situ synthesis of SiC nanofibers on graphite felt as a scaffold for improving performance of paraffin-based composite phase change materials. RSC Adv, 2021, 12: 878–887

Mo Z, Mo P, Yi M, et al. Ti3C2Tx@polyvinyl alcohol foam-supported phase change materials with simultaneous enhanced thermal conductivity and solar-thermal conversion performance. Sol Energy Mater Sol Cells, 2021, 219: 110813

Zhao S, Li J, Wu Y, et al. Three-dimensional interconnected porous TiO2 ceramics for high-temperature thermal storage. Renew Energy, 2021, 178: 701–708

Wu T, Li X, Xu W, et al. Scalable fabrication of high-enthalpy polyethylene/carbon nanotubes/paraffin wax nanocomposite with flexibility and superhydrophobicity for efficient thermal management. Compos Part A-Appl Sci Manuf, 2022, 159: 107006

Xiao S, Hu X, Jiang L, et al. Nano-Ag modified bio-based loofah foam/polyethylene glycol composite phase change materials with higher photo-thermal conversion efficiency and thermal conductivity. J Energy Storage, 2022, 54: 105238

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Key R&D Program of China (Grant No. 2018YFA0702300), and the Natural Science Foundation of Jiangsu Province (Grant Nos. BK20220009, BK20202008, BE2022024, BK20220001, BE2022602, and BK20220077).

Rights and permissions

About this article

Cite this article

Liu, X., Wei, P., Luo, Q. et al. From sawdust waste to high-value hierarchical ceramics-based phase change materials: Efficient dual functional thermal and solar energy storage. Sci. China Technol. Sci. 66, 2625–2636 (2023). https://doi.org/10.1007/s11431-022-2376-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2376-0