Abstract

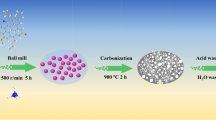

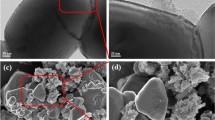

The water soluble coal tar pitches (WS-CTPs) were successfully prepared and used to construct the MnO2@C composite materials by a hydrothermal method. It is interestingly observed that the structures and morphologies of MnO2@C materials can be controlled by controlling the dosages of WS-CTPs and KMnO4. Meanwhile, it is aware that MnO2 exists in the MnO2@C materials in an amorphous state. Compared with MnO2, MnO2@C materials output a remarkable improvement in electrochemical performance. For instance, MnO2@C-0.3 shows the storage capacity at 965.7 mA h g−1 after 300 cycles at a current density of 0.1 A g−1. In addition, after 600 cycles at a current density of 1.0 A g−1, the storage capacity of MnO2@C-0.3 still keeps 450.3 mA h g−1, indicating that MnO2@C-0.3 owns tremendous cycle stability at a high current density. In view of the fact that the coal tar pitches possess great cost advantages, the strategy of using WS-CTPs as a carbon source to cover the metal oxides is a competitive way to expand the application of metal oxides in the fabrication of electrodes of LIBs.

Similar content being viewed by others

References

Huang Y, Tang Y, Yuan W, et al. Challenges and recent progress in thermal management with heat pipes for lithium-ion power batteries in electric vehicles. Sci China Tech Sci, 2021, 64: 919–956

Li J, Xu G, Wang K, et al. Study on fabrication and electrochemical performances of Fe7S8@C composite materials. Electrochemistry, 2020, 88: 380–386

Wang K, Ju D, Xu G, et al. Enhanced Li ion storage performances of carbon black by introducing organosulfur groups on surface. Electrochemistry, 2020, 88: 8–13

Wang K, Ju D, Xu G, et al. Study on electrochemical performances of composite carbon (FeO/C) materials fabricated by coal tar pitch and Fe3O4 particles. Int J Hydrogen Energy, 2019, 44: 25199–25206

Wang L, Nie Z, Cao C, et al. Carbon-wrapped TiO2 nanocubes exposed with (001) active facets for high-rate and long-life lithium-ion batteries. J Power Sources, 2016, 302: 259–265

Zhang J, Zhu Y, Cao C, et al. Microwave-assisted and large-scale synthesis of SnO2/carbon-nanotube hybrids with high lithium storage capacity. RSC Adv, 2015, 5: 58568–58573

Yang L, Wu Y, Wu Y, et al. Hierarchical flower-like Fe2O3 mesoporous nanosheets with superior electrochemical lithium storage performance. J Energy Storage, 2019, 23: 363–370

Khalid S, Cao C, Naveed M, et al. 3D hierarchical MnO2 microspheres: A prospective material for high performance supercapacitors and lithium-ion batteries. Sustain Energy Fuels, 2017, 1: 1795–1804

Tai Z, Shi M, Zhu W, et al. Carbon-coated β-MnO2 for cathode of lithium-ion battery. Sustain Energy Fuels, 2020, 4: 1704–1711

Zhang L, Song J, Liu Y, et al. Tailoring nanostructured MnO2 as anodes for lithium ion batteries with high reversible capacity and initial coulombic efficiency. J Power Sources, 2018, 379: 68–73

Meng Y, Liu Y, He J, et al. Large scale synthesis ofmanganese oxide/reduced graphene oxide composites as anode materials for long cycle lithium ion batteries. ACS Appl Energy Mater, 2021, 4: 5424–5433

Park J H, Choi W Y, Lee S, et al. Graphene intercalated free-standing carbon paper coated with MnO2 for anode materials of lithium ion batteries. Electrochim Acta, 2020, 348: 136310

Zhang M, Jin D, Zhang L, et al. High energy storage MnO2@C fabricated by ultrasonic-assisted stepwise electrodeposition and vapor carbon coating. Chem Eng J Adv, 2021, 6: 100098

Zeng H, Xing B, Zhang C, et al. In situ synthesis of MnO2/porous graphitic carbon composites as high-capacity anode materials for lithium-ion batteries. Energy Fuels, 2020, 34: 2480–2491

Abdollahi A, Abnavi A, Ghasemi F, et al. Facile synthesis and simulation of MnO2 nanoflakes on vertically aligned carbon nanotubes, as a high-performance electrode for Li-ion battery and supercapacitor. Electrochim Acta, 2021, 390: 138826

Song J, Li Y, Tong R, et al. MnxOy embedded within CNT supporting porous carbon for enhanced lithium storage. J Phys Chem Solids, 2022, 160: 110317

Wang Z, Yan X, Wang F, et al. Reduced graphene oxide thin layer induced lattice distortion in high crystalline MnO2 nanowires for high-performance sodium- and potassium-ion batteries and capacitors. Carbon, 2021, 174: 556–566

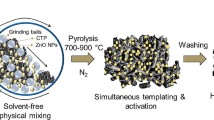

Xing B, Zhang C, Liu Q, et al. Green synthesis of porous graphitic carbons from coal tar pitch templated by nano-CaCO3 for high-performance lithium-ion batteries. J Alloys Compd, 2019, 795: 91–102

Li Y, Liu X, Liu L, et al. Coal tar electrode pitch modified rice husk ash as anode for lithium ion batteries. J Electrochem Soc, 2019, 166: A2425–A2430

Chen J, Yang K, Wang J, et al. Peanut-like yolk/core-shell MnO/C microspheres for improved lithium storage and the formation mechanism of MnCO3 precursors. J Alloys Compd, 2020, 849: 156637

Park S K, Jin A, Yu S H, et al. In situ hydrothermal synthesis of Mn3O4 nanoparticles on nitrogen-doped graphene as high-Performance anode materials for lithium ion batteries. Electrochim Acta, 2014, 120: 452–459

Bourlinos A B, Gournis D, Petridis D, et al. Graphite oxide: Chemical reduction to graphite and surface modification with primary aliphatic amines and amino acids. Langmuir, 2003, 19: 6050–6055

Szabó T, Berkesi O, Forgó P, et al. Evolution of surface functional groups in a series of progressively oxidized graphite oxides. Chem Mater, 2006, 18: 2740–2749

Wang K, Ju D Y, Xu G Y, et al. Organosilicon modified method to improve Li+ storage capacity of graphene oxide (GO). Sci China Tech Sci, 2020, 63: 2709–2716

Zhang W, Xu H, Xie F, et al. General synthesis of ultrafine metal oxide/reduced graphene oxide nanocomposites for ultrahigh-flux nanofiltration membrane. Nat Commun, 2022, 13: 471–480

Jia H N, Lin J H, Liu Y L, et al. Nanosized core-shell structured graphene-MnO2 nanosheet arrays as stable electrodes for superior supercapacitors. J Mater Chem A, 2017, 5: 10678–10686

Kim I G, Ghani F, Lee K, et al. Electrochemical performance of Mn3O4 nanorods by N-doped reduced graphene oxide using ultrasonic spray pyrolysis for lithium storage. Int J Energy Res, 2020, 44: 11171–11184

Ang Z W J, Xiong T, Lee W S V, et al. Oxygen-deficient birnessite-MnO2 for high-performing rechargeable aqueous zinc-ion batteries. ChemNanoMat, 2020, 6: 1357–1364

Cai Y, Chua R, Huang S, et al. Amorphous manganese dioxide with the enhanced pseudocapacitive performance for aqueous rechargeable zinc-ion battery. Chem Eng J, 2020, 396: 125221

Wang J, Zhang C, Kang F. Nitrogen-enriched porous carbon coating for manganese oxide nanostructures toward high-performance lithium-ion batteries. ACS Appl Mater Interfaces, 2015, 7: 9185–9194

Ao L, Wu C, Xu Y, et al. A novel Sn particles coated composite of SnO/ZnO and N-doped carbon nanofibers as high-capacity and cycle-stable anode for lithium-ion batteries. J Alloys Compd, 2020, 819: 153036

Huang S Z, Cai Y, Jin J, et al. Unique walnut-shaped porous MnO2/C nanospheres with enhanced reaction kinetics for lithium storage with high capacity and superior rate capability. J Mater Chem A, 2016, 4: 4264–4272

Li Z, Cai L, Chu K, et al. Heteroatom-doped carbon materials with interconnected channels as ultrastable anodes for lithium/sodium ion batteries. Dalton Trans, 2021, 50: 4335–4344

Schilling C, Hofmann A, Hess C, et al. Raman spectra of poly-crystalline CeO2: A density functional theory study. J Phys Chem C, 2017, 121: 20834–20849

Hattori T, Kobayashi K, Ozawa M. Size effect of Raman scattering on CeO2 nanocrystal by hydrothermal method. Jpn J Appl Phys, 2017, 56: 01AE06

Deng Z, Huang X, Zhao X, et al. Facile synthesis of hierarchically structured manganese oxides as anode for lithium-ion batteries. J Cent South Univ, 2019, 26: 1481–1492

Wan H, Ju X, He T, et al. Sulfur-doped porous carbon as high-capacity anodes for lithium and sodium ions batteries. J Alloys Compd, 2021, 863: 158078

Wei F, Zhang H, He X, et al. Synthesis of porous carbons from coal tar pitch for high-performance supercapacitors. New Carbon Mater, 2019, 34: 132–139

Luo J, Hu W, Suo Z, et al. Co-pyrolysis of spent radioactive ion exchange resin and manganese dioxide: Decrease the decomposition temperatures of functional groups. J Hazard Mater, 2021, 418: 126275

Zhong S, Zhang H, Fu J, et al. In-situ synthesis of 3D carbon coated zinc-cobalt bimetallic oxide networks as anode in lithium-ion batteries. ChemElectroChem, 2018, 5: 1708–1716

Vijayan B L, Misnon II, Anil Kumar G M, et al. Facile fabrication of thin metal oxide films on porous carbon for high density charge storage. J Colloid Interface Sci, 2020, 562: 567–577

Moon S, Kim D H, Kwak J H, et al. Unveiling the pseudocapacitive effects of ultramesopores on nanoporous carbon. Appl Surf Sci, 2021, 537: 148037

Jia Y, Yang Z, Li H, et al. Reduced graphene oxide encapsulated MnO microspheres as an anode for high-rate lithium ion capacitors. New Carbon Mater, 2021, 36: 573–584

Oh S M, Kim I Y, Adpakpang K, et al. The beneficial effect of nanocrystalline and amorphous nature on the anode performance of manganese oxide for lithium ion batteries. Electrochim Acta, 2015, 174: 391–399

Wu H, Zhou S, Tseng C, et al. One-pot solution combustion synthesis of crystalline and amorphous molybdenum trioxide as anode for lithium-ion battery. J Am Ceram Soc, 2020, 104: 1102–1109

Wu Y, Fee J, Tobin Z, et al. Amorphous manganese oxides: An approach for reversible aqueous zinc-ion batteries. ACS Appl Energy Mater, 2020, 3: 1627–1633

Chen M, Liu J, Chao D, et al. Porous a-Fe2O3 nanorods supported on carbon nanotubes-graphene foam as superior anode for lithium ion batteries. Nano Energy, 2014, 9: 364–372

Jadhav H S, Rai A K, Lee J Y, et al. Enhanced electrochemical performance of flower-like Co3O4 as an anode material for high performance lithium-ion batteries. Electrochim Acta, 2014, 146: 270–277

Jia B, Chen W, Luo J, et al. Construction of MnO2 artificial leaf with atomic thickness as highly stable battery anodes. Adv Mater, 2020, 32: 1906582

Gogotsi Y, Penner R M. Energy storage in nanomaterials-capacitive, pseudocapacitive, or battery-like? ACS Nano, 2018, 12: 2081–2083

Choi C, Ashby D S, Butts D M, et al. Achieving high energy density and high power density with pseudocapacitive materials. Nat Rev Mater, 2020, 5: 5–19

Wang X, Liu J, Hu Y, et al. Oxygen vacancy-expedited ion diffusivity in transition-metal oxides for high-performance lithium-ion batteries. Sci China Mater, 2022, 65: 1421–1430

Fang G, Wu Z, Zhou J, et al. Observation of pseudocapacitive effect and fast ion diffusion in bimetallic sulfides as an advanced sodium-ion battery anode. Adv Energy Mater, 2018, 8: 1703155

Wang Y, Liu H, Wang K, et al. Synthesis and electrochemical performance of nano-sized Li4Ti5O12 with double surface modification of Ti(III) and carbon. J Mater Chem, 2009, 19: 6789–6795

Zhu K, Wang X, Liu J, et al. Novel amorphous MoS2/MoO3/nitrogen-doped carbon composite with excellent electrochemical performance for lithium ion batteries and sodium ion batteries. ACS Sustain Chem Eng, 2017, 5: 8025–8034

Zhang Y, Chen P, Wang Q, et al. High-capacity and kinetically accelerated lithium storage in MoO3 enabled by oxygen vacancies and heterostructure. Adv Energy Mater, 2021, 11: 2101712

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the University of Science and Technology Liaoning (Grant Nos. 601009816-39 and 2017RC03), the Liaoning Province Education Department of China (Grant Nos. 601009887-16 and LJKQZ2021126), the National Natural Science Foundation of China (Grant Nos. 51672117 and 51672118), and the Postdoctoral Foundation Project of Shenzhen Polytechnic (Grant No. 6020330007K).

Supporting Information

The supporting information is available online at tech.scichina.com and link.springer.com. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors

Supporting Information

11431_2022_2335_MOESM1_ESM.pdf

A strategy based on water soluble coal tar pitches to construct MnO2@C composite materials with high electrochemical performance

Rights and permissions

About this article

Cite this article

Liu, B., Wang, K., Guo, Z. et al. A strategy based on water soluble coal tar pitches to construct MnO2@C composite materials with high electrochemical performance. Sci. China Technol. Sci. 67, 311–320 (2024). https://doi.org/10.1007/s11431-022-2335-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2335-8