Abstract

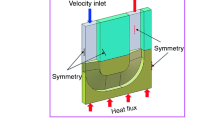

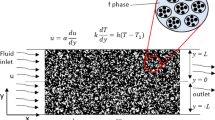

A numerical model is developed for three-dimensional droplet mixing in serpentine microchannels with inner-wall ridges (referred to as SMR microchannels). The underlying mechanisms of mixing in SMR microchannels are revealed, and the effects of the ridge width and ridge number on mixing inside droplets of different sizes are clarified. The results indicate that SMR microchannels are capable of enhancing the mixing efficiency by 3.6%–12.5% compared with that in smooth serpentine microchannels, particularly when the droplet length is larger than the microchannel width and the width ratio of the ridge to the microchannel is 0.25–1. The above mixing enhancement is determined by two main factors: the combined effects of the vortex pair and reverse flow, and non-horizontal vortices. Moreover, when the width ratio is 1, there is a maximum 16.0% increase in mixing efficiency for small droplets with a length equal to the microchannel width. However, for small droplets, mixing in an SMR microchannel is worse than in a smooth serpentine microchannel when the width ratio is less than 0.75. With increasing the ridge number, when the width ratio is 0.25, the mixing efficiency is reduced for small droplets but increased for larger droplets.

Similar content being viewed by others

References

Churski K, Korczyk P, Garstecki P. High-throughput automated droplet microfluidic system for screening of reaction conditions. Lab Chip, 2010, 10: 816–818

Casadevall i Solvas X, deMello A. Droplet microfluidics: Recent developments and future applications. Chem Commun, 2011, 47: 1936–1942

Song H, Ismagilov R F. Millisecond kinetics on a microfluidic chip using nanoliters of reagents. J Am Chem Soc, 2003, 125: 14613–14619

Song H, Chen D L, Ismagilov R F. Reactions in droplets in microfluidic channels. Angew Chem Int Ed, 2006, 45: 7336–7356

Sarrazin F, Prat L, Di Miceli N, et al. Mixing characterization inside microdroplets engineered on a microcoalescer. Chem Eng Sci, 2007, 62: 1042–1048

Liau A, Karnik R, Majumdar A, et al. Mixing crowded biological solutions in milliseconds. Anal Chem, 2005, 77: 7618–7625

Grigoriev R O, Schatz M F, Sharma V. Chaotic mixing in microdroplets. Lab Chip, 2006, 6: 1369–1372

Gissinger J R, Zinchenko A Z, Davis R H. Internal circulation and mixing within tight-squeezing deformable droplets. Phys Rev E, 2021, 103: 043106

Song H, Tice J D, Ismagilov R F. A microfluidic system for controlling reaction networks in time. Angew Chem Int Ed, 2003, 42: 768–772

Aref H, Blake J R, Budišić M, et al. Frontiers of chaotic advection. Rev Mod Phys, 2017, 89: 025007

Stone Z B, Stone H A. Imaging and quantifying mixing in a model droplet micromixer. Phys Fluids, 2005, 17: 063103

Bringer M R, Gerdts C J, Song H, et al. Microfluidic systems for chemical kinetics that rely on chaotic mixing in droplets. Philos Trans R Soc London Ser A-Math Phys Eng Sci, 2004, 362: 1087–1104

Bai L, Fu Y, Yao M, et al. Enhancement of mixing inside ionic liquid droplets through various micro-channels design. Chem Eng J, 2018, 332: 537–547

Ghazimirsaeed E, Madadelahi M, Dizani M, et al. Secondary flows, mixing, and chemical reaction analysis of droplet-based flow inside serpentine microchannels with different cross sections. Langmuir, 2021, 37: 5118–5130

Yin B, Luo H. Numerical simulation of drops inside an asymmetric microchannel with protrusions. Comput Fluids, 2013, 82: 14–28

Tanthapanichakoon W, Aoki N, Matsuyama K, et al. Design of mixing in microfluidic liquid slugs based on a new dimensionless number for precise reaction and mixing operations. Chem Eng Sci, 2006, 61: 4220–4232

Ottino J M, Muzzio F J, Tjahjadi M, et al. Chaos, symmetry, and self-similarity: Exploiting order and disorder in mixing processes. Science, 1992, 257: 754–760

Song H, Bringer M R, Tice J D, et al. Experimental test of scaling of mixing by chaotic advection in droplets moving through microfluidic channels. Appl Phys Lett, 2003, 83: 4664–4666

Wang J, Wang J, Feng L, et al. Fluid mixing in droplet-based microfluidics with a serpentine microchannel. RSC Adv, 2015, 5: 104138–104144

Cao X, Zhou B, Yu C, et al. Droplet-based mixing characteristics in bumpy serpentine microchannel. Chem Eng Processing-Process Intensification, 2021, 159: 108246

Olbricht W L, Leal L G. The creeping motion of immiscible drops through a converging/diverging tube. J Fluid Mech, 1983, 134: 329–355

Gai Y, Khor J W, Tang S K Y. Confinement and viscosity ratio effect on droplet break-up in a concentrated emulsion flowing through a narrow constriction. Lab Chip, 2016, 16: 3058–3064

Stroock A D, Dertinger S K W, Ajdari A, et al. Chaotic mixer for microchannels. Science, 2002, 295: 647–651

Chen Y, Yao F, Huang X. Mass transfer and reaction in methanol steam reforming reactor with fractal tree-like microchannel network. Int J Heat Mass Transfer, 2015, 87: 279–283

Shimokusu T J, Maybruck V G, Ault J T, et al. Colloid separation by CO2-induced diffusiophoresis. Langmuir, 2020, 36: 7032–7038

Liu Z H, Xu H Z, Chen W C, et al. Dispersion characteristics of liquid jet impacting on the rotating single-layer wire mesh with different surface wettabilities. Chem Eng Sci, 2022, 251: 117495

Hirt C W, Nichols B D. Volume of fluid (vof) method for the dynamics of free boundaries. J Comput Phys, 1981, 39: 201–225

Wang J X, Yu W, Wu Z, et al. Physics-based statistical learning perspectives on droplet formation characteristics in microfluidic cross-junctions. Appl Phys Lett, 2022, 120: 204101

Cao Y H, Xin M. Numerical simulation of ice accretion in supercooled large droplet conditions. Sci China Tech Sci, 2019, 62: 1191–1201

Brackbill J U, Kothe D B, Zemach C. A continuum method for modeling surface tension. J Comput Phys, 1992, 100: 335–354

Shang L, Yu Y, Gao W, et al. Bio-inspired anisotropic wettability surfaces from dynamic ferrofluid assembled templates. Adv Funct Mater, 2018, 28: 1705802

Wang J X, Birbarah P, Docimo D, et al. Nanostructured jumping-droplet thermal rectifier. Phys Rev E, 2021, 103: 023110

Chen Y, Zhang C, Shi M, et al. Slip boundary for fluid flow at rough solid surfaces. Appl Phys Lett, 2012, 100: 074102

Giacomin A J, Jbara L M, Saengow C. Pattern method for higher harmonics from macromolecular orientation in oscillatory shear flow. Phys Fluids, 2020, 32: 011703

Cao X, Hao G, Li Y, et al. On male urination and related environmental disease transmission in restrooms: From the perspectives of fluid dynamics. Sust Cities Soc, 2022, 80: 103753

Wang J X, Cao X, Chen Y P. An air distribution optimization of hospital wards for minimizing cross-infection. J Clean Prod, 2021, 279: 123431

Song Y, Liu Q, Wang Z, et al. Super-wetting enabled by an array of SU-8 micro-pillars etched with ion-beam. J Micromech Microeng, 2020, 30: 115010

Yin Q, Guo Q, Wang Z, et al. 3D-printed bioinspired cassie-baxter wettability for controllable microdroplet manipulation. ACS Appl Mater Interfaces, 2021, 13: 1979–1987

Tian F B, Dai H, Luo H, et al. Fluid-structure interaction involving large deformations: 3D simulations and applications to biological systems. J Comput Phys, 2014, 258: 451–469

Jiang C B, Deng B, Hu S X, et al. Numerical investigation of swash zone hydrodynamics. Sci China Tech Sci, 2013, 56: 3093–3103

Jiang L, Zeng Y, Zhou H, et al. Visualizing millisecond chaotic mixing dynamics in microdroplets: A direct comparison of experiment and simulation. Biomicrofluidics, 2012, 6: 012810

Xia H M, Wan S Y M, Shu C, et al. Chaotic micromixers using two-layer crossing channels to exhibit fast mixing at low Reynolds numbers. Lab Chip, 2005, 5: 748–755

Maleki M A, Soltani M, Kashaninejad N, et al. Effects of magnetic nanoparticles on mixing in droplet-based microfluidics. Phys Fluids, 2019, 31: 032001

Verma R K, Ghosh S. Effect of phase properties on liquid-liquid two-phase flow patterns and pressure drop in serpentine mini geometry. Chem Eng J, 2020, 397: 125443

Mohammadi A, Floryan J M. Pressure losses in grooved channels. J Fluid Mech, 2013, 725: 23–54

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51725602 and 52036006).

Supporting Information

The supporting information is available online at https://tech.scichina.com and https://link.springer.com. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Cao, X., Chen, Y. Design and numerical analysis of serpentine microchannel integrated with inner-wall ridges for enhanced droplet mixing. Sci. China Technol. Sci. 66, 560–573 (2023). https://doi.org/10.1007/s11431-022-2284-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2284-9