Abstract

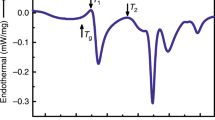

Structural rejuvenation is vital and attractive for modulating the energetic state and structural heterogeneity of bulk metallic glasses (BMGs). In this paper, we show that cooling a BMG from a supercooled liquid region at laboratory rates can reverse the relaxation enthalpy lost during the preceding structural relaxation. Increasing the cooling rate is beneficial for enhancing atomic mobility and dynamic mechanical relaxation intensity. Therefore, this rejuvenation methodology promotes tailoring the mechanical properties of BMGs and provides a comprehensive understanding of the rejuvenation mechanism.

Similar content being viewed by others

References

Qiao J C, Wang Q, Pelletier J M, et al. Structural heterogeneities and mechanical behavior of amorphous alloys. Prog Mater Sci, 2019, 104: 250–329

Johnson W. Thermodynamic and kinetic aspects of the crystal to glass transformation in metallic materials. Prog Mater Sci, 1986, 30: 81–134

Rao W, Chen Y, Dai L H. A constitutive model for metallic glasses based on two-temperature nonequilibrium thermodynamics. Int J Plast, 2022, 154: 103309

Kube S A, Sohn S, Ojeda-Mota R, et al. Compositional dependence of the fragility in metallic glass forming liquids. Nat Commun, 2022, 13: 3708

Zhang L T, Wang Y J, Pineda E, et al. Achieving structural rejuvenation in metallic glass by modulating β relaxation intensity via easy-to-operate mechanical cycling. Int J Plast, 2022, 157: 103402

Greer A L, Cheng Y Q, Ma E. Shear bands in metallic glasses. Mater Sci Eng-R-Rep, 2013, 74: 71–132

Lü Y J, Guo C C, Huang H S, et al. Quantized aging mode in metallic glass-forming liquids. Acta Mater, 2021, 211: 116873

Luckabauer M, Hayashi T, Kato H, et al. Decreasing activation energy of fast relaxation processes in a metallic glass during aging. Phys Rev B, 2019, 99: 140202

Pan J, Wang Y X, Guo Q, et al. Extreme rejuvenation and softening in a bulk metallic glass. Nat Commun, 2018, 9: 560

Ketov S V, Sun Y H, Nachum S, et al. Rejuvenation of metallic glasses by non-affine thermal strain. Nature, 2015, 524: 200–203

Sun Y, Concustell A, Greer A L. Thermomechanical processing of metallic glasses: Extending the range of the glassy state. Nat Rev Mater, 2016, 1: 16039

Ding G, Li C, Zaccone A, et al. Ultrafast extreme rejuvenation of metallic glasses by shock compression. Sci Adv, 2019, 5: eaaw6249

Pan J, Ivanov Y P, Zhou W H, et al. Strain-hardening and suppression of shear-banding in rejuvenated bulk metallic glass. Nature, 2020, 578: 559–562

Greer A L, Sun Y H. Stored energy in metallic glasses due to strains within the elastic limit. Philos Mag, 2016, 96: 1643–1663

Zhang L, Wang Y, Yang Y, et al. Aging and rejuvenation during high-temperature deformation in a metallic glass. Sci China-Phys Mech Astron, 2022, 65: 106111

Kosiba K, Şopu D, Scudino S, et al. Modulating heterogeneity and plasticity in bulk metallic glasses: Role of interfaces on shear banding. Int J Plast, 2019, 119: 156–170

Zhu F, Song S, Reddy K M, et al. Spatial heterogeneity as the structure feature for structure-property relationship of metallic glasses. Nat Commun, 2018, 9: 3965

Tsai P, Kranjc K, Flores K M. Hierarchical heterogeneity and an elastic microstructure observed in a metallic glass alloy. Acta Mater, 2017, 139: 11–20

Qiao J C, Zhang L T, Tong Y, et al. Mechancial properties of amorphous alloys: In the framework of the microstructure heterogeneity. Adv Mech, 2022, 52: 117–152

Küchemann S, Maaß R. Gamma relaxation in bulk metallic glasses. Scripta Mater, 2017, 137: 5–8

Jiang W, Zhang B. Strong beta relaxation in high entropy bulk metallic glasses. J Appl Phys, 2020, 117: 115104

Afonin G V, Zamyatin O A, Zamyatina E V, et al. Thermal rejuvenation of tellurite glasses by cooling from the supercooled liquid state at low rates. Scripta Mater, 2020, 186: 39–42

Stolpe M, Kruzic J J, Busch R. Evolution of shear bands, free volume and hardness during cold rolling of a Zr-based bulk metallic glass. Acta Mater, 2014, 64: 231–240

Zhang L T, Duan Y J, Pineda E, et al. Effect of physical aging and cyclic loading on power-law creep of high-entropy metallic glass. J Mater Sci Technol, 2022, 115: 1–9

Böhmer R, Ngai K L, Angell C A, et al. Nonexponential relaxations in strong and fragile glass formers. J Chem Phys, 1993, 99: 4201–4209

Wang W H. Dynamic relaxations and relaxation-property relationships in metallic glasses. Prog Mater Sci, 2019, 106: 100561

Zhang L T, Duan Y J, Crespo D, et al. Dynamic mechanical relaxation and thermal creep of high-entropy La30Ce30Ni10Al20Co10 bulk metallic glass. Sci China-Phys Mech Astron, 2021, 64: 296111

Wang B, Wang L J, Shang B S, et al. Revealing the ultra-low-temperature relaxation peak in a model metallic glass. Acta Mater, 2020, 195: 611–620

Dmowski W, Iwashita T, Chuang C P, et al. Elastic heterogeneity in metallic glasses. Phys Rev Lett, 2010, 105: 205502

Spaepen F. Homogeneous flow of metallic glasses: A free volume perspective. Scripta Mater, 2006, 54: 363–367

Argon A S. Plastic deformation in metallic glasses. Acta Metall, 1979, 27: 47–58

Perez J. Quasi-punctual defects in vitreous solids and liquid-glass transition. Solid State Ion, 1990, 39: 69–79

Hao Q, Lyu G J, Pineda E, et al. A hierarchically correlated flow defect model for metallic glass: Universal understanding of stress relaxation and creep. Int J Plast, 2022, 154: 103288

Qiao J C, Cong J, Wang Q, et al. Effects of iron addition on the dynamic mechanical relaxation of Zr55Cu30Ni5Al10 bulk metallic glasses. J Alloys Compd, 2018, 749: 262–267

Wang C H, Hu Y J, Qiao J C, et al. Mechanical relaxation behavior of Zr64.13Cu15.75Ni10.12Al10 bulk metallic glass. Mater Sci Eng-A, 2018, 738: 57–62

Angell C A, Ngai K L, McKenna G B, et al. Relaxation in glass-forming liquids and amorphous solids. J Appl Phys, 2000, 88: 3113–3157

Wada T, Inoue A. Formation of porous Pd-based bulk glassy alloys by a high hydrogen pressure melting-water quenching method and their mechanical properties. Mater Trans, 2004, 45: 2761–2765

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51971178 and 52271153), the Natural Science Basic Research Plan for Distinguished Young Scholars in Shaanxi Province (Grant No. 2021JC-12) and the Natural Science Foundation of Chongqing (Grant No. cstc2020jcyj-jqX0001). The investigation of LangTing ZHANG is sponsored by the Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University (Grant No. CX2021015). YunJiang WANG was financially supported by National Natural Science Foundation of China (Grant No. 12072344) and the Youth Innovation Promotion Association of the Chinese Academy of Sciences. Yong YANG acknowledges financial support from Research Grant Council (RGC) and the Hong Kong government through the General Research Fund (GRF) (Grant Nos. U11200719 and U11213118).

Rights and permissions

About this article

Cite this article

Zhang, L., Duan, Y., Wang, Y. et al. Tailoring the mechanical properties of bulk metallic glasses via cooling from the supercooled liquid region. Sci. China Technol. Sci. 66, 173–180 (2023). https://doi.org/10.1007/s11431-022-2237-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2237-5