Abstract

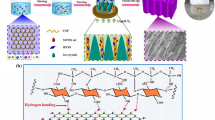

Porous foam based on renewable materials has attracted extensive attention in green energy conservation and sustainable development. However, there is still a requisite for biomass-based porous foam that could meet the demand for excellent mechanical and high thermal insulation performances for building insulation. Herein, we demonstrated a facile strategy to prepare a porous foam made from a chitosan matrix reinforced by SiC whisker, which shows good performance in building insulation and mechanical strength. The prepared porous foam has a low density (20.1–54.4 kg m−3) and high porosity (>97.0%). The density of the chitosan-SiC porous foam can be controlled by varying the suspension solid and SiC whisker content in the preparation process. Furthermore, the influences of SiC whisker content on the mechanical properties and thermal conductivity of the porous foams were also investigated. When the content of SiC whisker is 30 wt%, the prepared porous foam has the highest compression modulus of about 89.8 kPa and also low thermal conductivity of 0.0354 W m−1 K−1. Moreover, the prepared porous foam shows excellent water vapor permeability with a vapor resistance factor of 2.94, which is beneficial for moisture transfer in buildings. This work provides a facile way to manufacture biomass based porous foam, which is potential for energy saving in buildings.

Similar content being viewed by others

References

Li Y, Chen X, Wang X, et al. A review of studies on green building assessment methods by comparative analysis. Energy Buildings, 2017, 146: 152–159

Dénes T O, Iştoan R, Tǎmaş-Gavrea D R, et al. Analysis of sheep wool-based composites for building insulation. Polymers, 2022, 14: 2109

Abu-Jdayil B, Mourad A H, Hittini W, et al. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Construct Build Mater, 2019, 214: 709–735

Li D, Huang C. Thermal insulation performances of carbonized sawdust packed bed for energy saving in buildings. Energy Build, 2022, 254: 111625

Zhang H M. Heat-insulating materials and sound-absorbing materials. In: Building Materials in Civil Engineering. Woodhead Publishing Series in Civil and Structural Engineering. Cambridge: Woodhead Publishing, 2011. 304–315

Dylewski R, Adamczyk J. Life cycle assessment (LCA) of building thermal insulation materials. In: Eco-efficient Construction and Building Materials. Life Cycle Assessment (LCA), Eco-Labelling and Case Studies. Cambridge: Woodhead Publishing Limited, 2014. 267–286

Ibrahim M, Wurtz E, Biwole P H, et al. Performance evaluation of buildings with advanced thermal insulation system: A numerical study. J Facade Design Eng, 2016, 4: 19–34

Fan J, Hui S, Bailey T P, et al. Ultralow thermal conductivity in grapheme-silica porous ceramics with a special saucer structure of graphene aerogels. J Mater Chem A, 2019, 7: 1574–1584

Huang C, Lin Z, Feng Y, et al. Thermal conductivity of silica nanoparticle powder: Measurement and theoretical analysis. Eur Phys J Plus, 2015, 130: 239

Zeng Q, Mao T, Li H, et al. Thermally insulating lightweight cement-based composites incorporating glass beads and nano-silica aerogels for sustainably energy-saving buildings. Energy Buildings, 2018, 174: 97–110

Zhang X, Wang F, Dou L, et al. Ultrastrong, superelastic, and lamellar multiarch structured ZrO2-Al2O3 nanofibrous aerogels with high-temperature resistance over 1300°C. ACS Nano, 2020, 14: 15616–15625

Zhang E, Zhang W, Lv T, et al. Insulating and robust ceramic nanorod aerogels with high-temperature resistance over 1400°C. ACS Appl Mater Interfaces, 2021, 13: 20548–20558

Yoo S, Kandare E, Shanks R, et al. Thermophysical properties of multifunctional glass fibre reinforced polymer composites incorporating phase change materials. Thermochim Acta, 2016, 642: 25–31

Tang X, Sun A, Chu C, et al. A novel silica nanowire-silica composite aerogels dried at ambient pressure. Mater Des, 2017, 115: 415–421

Zhao W, Zhao H B, Cheng J B, et al. A green, durable and effective flame-retardant coating for expandable polystyrene foams. Chem Eng J, 2022, 440: 135807

Ma Z, Liu X, Xu X, et al. Bioinspired, highly adhesive, nanostructured polymeric coatings for superhydrophobic fire-extinguishing thermal insulation foam. ACS Nano, 2021, 15: 11667–11680

Reinerte S, Kirpluks M, Cabulis U. Thermal degradation of highly crosslinked rigid PU-PIR foams based on high functionality tall oil polyol. Polym Degrad Stability, 2019, 167: 50–57

Cavasin M, Giannis S, Salvo M, et al. Mechanical and thermal characterization of an epoxy foam as thermal layer insulation for a glass fiber reinforced polymer. J Appl Polym Sci, 2018, 135: 46864

Yang H, Jiang Y, Liu H, et al. Mechanical, thermal and fire performance of an inorganic-organic insulation material composed of hollow glass microspheres and phenolic resin. J Colloid Interface Sci, 2018, 530: 163–170

Zhu Z, Snellings G M BF, Koebel M M, et al. Superinsulating polyisocyanate based aerogels: A targeted search for the optimum solvent system. ACS Appl Mater Interfaces, 2017, 9: 18222–18230

Liu L, Zou S, Li H, et al. Experimental physical properties of an eco-friendly bio-insulation material based on wheat straw for buildings. Energy Buildings, 2019, 201: 19–36

Tiuc A E, Nemeş O, Vermesan H, et al. New sound absorbent composite materials based on sawdust and polyurethane foam. Compos Part B-Eng, 2019, 165: 120–130

Wei K, Lv C, Chen M, et al. Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing. Energy Buildings, 2015, 87: 116–122

Druel L, Bardl R, Vorwerg W, et al. Starch aerogels: A member of the family of thermal superinsulating materials. Biomacromolecules, 2017, 18: 4232–4239

Zhao S, Malfait W J, Guerrero-Alburquerque N, et al. Biopolymer aerogels and foams: Chemistry, properties, and applications. Angew Chem Int Ed, 2018, 57: 7580–7608

Wang Y, Wu K, Xiao M, et al. Thermal conductivity, structure and mechanical properties of konjac glucomannan/starch based aerogel strengthened by wheat straw. Carbohydrate Polyms, 2018, 197: 284–291

Raman S P, Gurikov P, Smirnova I. Hybrid alginate based aerogels by carbon dioxide induced gelation: Novel technique for multiple applications. J Supercrit Fluids, 2015, 106: 23–33

Zhu J, Xiong R, Zhao F, et al. Lightweight, high-strength, and anisotropic structure composite aerogel based on hydroxyapatite nanocrystal and chitosan with thermal insulation and flame retardant properties. ACS Sustain Chem Eng, 2020, 8: 71–83

Kolaitis D I, Malliotakis E, Kontogeorgos D A, et al. Comparative assessment of internal and external thermal insulation systems for energy efficient retrofitting of residential buildings. Energy Buildings, 2013, 64: 123–131

Ismail B, Belayachi N, Hoxha D. Hygric properties of wheat straw biocomposite containing natural additives intended for thermal insulation of buildings. Constr Build Mater, 2022, 317: 126049

Zou F, Budtova T. Polysaccharide-based aerogels for thermal insulation and superinsulation: An overview. Carbohydrate Polyms, 2021, 266: 118130

Ma Q, Liu Y, Dong Z, et al. Hydrophobic and nanoporous chitosan-silica composite aerogels for oil absorption. J Appl Polym Sci, 2015, 132: 41770

Xiao W, Wang P, Song X, et al. Facile fabrication of anisotropic chitosan aerogel with hydrophobicity and thermal superinsulation for advanced thermal management. ACS Sustain Chem Eng, 2021, 9: 9348–9357

Zhang S, Feng J, Feng J, et al. Ultra-low shrinkage chitosan aerogels trussed with polyvinyl alcohol. Mater Des, 2018, 156: 398–406

Chen J, Xie H, Lai X, et al. An ultrasensitive fire-warning chitosan/montmorillonite/carbon nanotube composite aerogel with high fire-resistance. Chem Eng J, 2020, 399: 125729

Wu R, Zhou K, Yue C Y, et al. Recent progress in synthesis, properties and potential applications of SiC nanomaterials. Prog Mater Sci, 2015, 72: 1–60

Meng S, Jin G Q, Wang Y Y, et al. Tailoring and application of SiC nanowires in composites. Mater Sci Eng-A, 2010, 527: 5761–5765

Dash S, Swain S K. Synthesis of thermal and chemical resistant oxygen barrier starch with reinforcement of nano silicon carbide. Carbohydrate Polyms, 2013, 97: 758–763

Pozuelo M, Kao W H, Yang J M. High-resolution TEM characterization of SIC nanowires as reinforcements in a nanocrystalline Mg-matrix. Mater Charact, 2013, 77: 81–88

Jiraborvornpongsa N, Imai M, Yoshida K, et al. Effects of trace amount of nanometric SiC additives with wire or particle shapes on the mechanical and thermal properties of alumina matrix composites. J Mater Sci, 2013, 48: 7022–7027

Yang W, Araki H, Tang C, et al. Single-crystal SiC nanowires with a thin carbon coating for stronger and tougher ceramic composites. Adv Mater, 2005, 17: 1519–1523

Ferraro C, Garcia-Tuñon E, Rocha V G, et al. Light and strong SiC networks. Adv Funct Mater, 2016, 26: 1636–1645

Saravanan L, Subramanian S, Kumar A B V, et al. Surface chemical studies on SiC suspension in the presence of chitosan. Ceramics Int, 2006, 32: 637–646

Cervin N T, Aulin C, Larsson P T, et al. Ultra porous nanocellulose aerogels as separation medium for mixtures of oil/water liquids. Cellulose, 2012, 19: 401–410

Zhao S, Zhang Z, Sèbe G, et al. Multiscale assembly of super-insulating silica aerogels within silylated nanocellulosic scaffolds: improved mechanical properties promoted by nanoscale chemical compatibilization. Adv Funct Mater, 2015, 25: 2326–2334

Zhou S, Apostolopoulou-Kalkavoura V, Tavares da Costa M V, et al. Elastic aerogels of cellulose nanofibers@metal-organic frameworks for thermal insulation and fire retardancy. Nano-Micro Lett, 2020, 12: 9

Pujar V V, Cawley J D. Effect of stacking faults on the X-ray diffraction profiles of beta-SiC powders. J Am Ceramic Soc, 1995, 78: 774–782

Tang E S K, Huang M, Lim L Y. Ultrasonication of chitosan and chitosan nanoparticles. Int J Pharm, 2003, 265: 103–114

Zhan H, Zhang N, Wu D, et al. Controlled synthesis of β-SiC with a novel microwave sintering method. Mater Lett, 2019, 255: 126586

Yan J, Wu T, Ding Z, et al. Preparation and characterization of carbon nanotubes/chitosan composite foam with enhanced elastic property. Carbohydrate Polyms, 2016, 136: 1288–1296

Luo X, Shen J, Ma Y, et al. Robust, sustainable cellulose composite aerogels with outstanding flame retardancy and thermal insulation. Carbohydrate Polyms, 2020, 230: 115623

Xu G, Wang K, Zhong Z, et al. SiC nanofiber reinforced porous ceramic hollow fiber membranes. J Mater Chem A, 2014, 2: 5841–5846

Rahim M, Douzane O, Tran Le A D, et al. Characterization of flax lime and hemp lime concretes: Hygric properties and moisture buffer capacity. Energy Buildings, 2015, 88: 91–99

Liu Y, Cao Z, Wang Y, et al. Experimental study of hygro-thermal characteristics of novel cement-cork mortars. Constr Build Mater, 2021, 271: 121901

Nguyen D M, Grillet A C, Bui Q B, et al. Building bio-insulation materials based on bamboo powder and bio-binders. Constr Build Mater, 2018, 186: 686–698

Collet F, Prétot S, Lanos C. Hemp-straw composites: Thermal and hygric performances. Energy Procedia, 2017, 139: 294–300

Cetiner I, Shea A D. Wood waste as an alternative thermal insulation for buildings. Energy Buildings, 2018, 168: 374–384

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant No. 52076211).

Rights and permissions

About this article

Cite this article

Li, D., Gao, G. & Huang, C. Chitosan foam reinforced by SiC whisker for building insulation with high mechanical strength and vapor permeability. Sci. China Technol. Sci. 65, 2874–2882 (2022). https://doi.org/10.1007/s11431-022-2203-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2203-7