Abstract

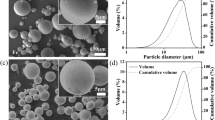

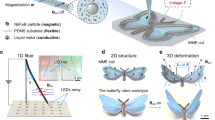

The simultaneous placement of different types of materials including polymers, ceramics, and metals, in their desired positions could be adopted to manufacture end-use devices/apparatuses with diverse functionalities and significantly reduce the fabrication cost and time. However, existing additive manufacturing (AM) approaches can only treat one material species at a time due to their intrinsic working mechanisms. Here we develop an AM manipulator for manufacturing a wide variety of material species, including polymers, ceramics, and metals, through a multifilament transport strategy assisted by laser power. The six-jaw manipulator contains three pairs of filament delivering/cutting systems for transporting diverse materials and a beam of tunable laser as the thermal source. The whole apparatus is integrated into a robotic manipulator to create a multifreedom manufacturing platform. With this innovation, products with multiple material species and desired complex geometries can be fabricated on demand. Furthermore, we synthesize a multimaterial (polymer/ceramic/metal) printed magnetoelectric pressure sensor that can convert applied mechanical forces to electricity and maintain efficiency even after undergoing 10000 cycles of pressure/recovery. With this multimaterial filament transport and laser manufacturing strategy, our AM manipulator exhibits promising application in the advanced manufacturing of embedded electronics, sensors, soft robotics, and customizable medical devices.

Similar content being viewed by others

References

Gu D, Shi X, Poprawe R, et al. Material-structure-performance integrated laser-metal additive manufacturing. Science, 2021, 372: eabg1487

Robertson I D, Yourdkhani M, Centellas P J, et al. Rapid energy-efficient manufacturing of polymers and composites via frontal polymerization. Nature, 2018, 557: 223–227

Song J, Chen C, Zhu S, et al. Processing bulk natural wood into a high-performance structural material. Nature, 2018, 554: 224–228

Luo Y, Wang M, Wan C, et al. Devising materials manufacturing toward lab-to-fab translation of flexible electronics. Adv Mater, 2020, 32: 2001903

Chimene D, Kaunas R, Gaharwar A K. Hydrogel bioink reinforcement for additive manufacturing: A focused review of emerging strategies. Adv Mater, 2020, 32: 1902026

Wu Z, Ai J, Huang J, et al. A ball-in-ball type self-powered magnetoelectric inertial sensor for 3D multi-angle motion monitoring of humanoid robots. Nano Energy, 2021, 85: 106016

Zhang X, Wang Q, Zou R, et al. 3D-Printed superhydrophobic and magnetic device that can self-powered sense a tiny droplet impact. Engineering, 2022, 15: 196–205

Ma Z, Wang Q, Wu Z, et al. Superconducting material based maglev generator used for outer-space. Adv Mater, 2022, 34: 2203814

Li L, Ota K, Dong M. Deep learning for smart industry: Efficient manufacture inspection system with fog computing. IEEE Trans Ind Inf, 2018, 14: 4665–4673

Dietrich P I, Blaicher M, Reuter I, et al. In situ 3D nanoprinting of free-form coupling elements for hybrid photonic integration. Nat Photon, 2018, 12: 241–247

Mohammed M G, Kramer R. All-printed flexible and stretchable electronics. Adv Mater, 2017, 29: 1604965

Mitchell A, Lafont U, Hołyńska M, et al. Additive manufacturing—A review of 4D printing and future applications. Addit Manuf, 2018, 24: 606–626

MacDonald E, Wicker R. Multiprocess 3D printing for increasing component functionality. Science, 2016, 353: aaf2093

Naranjo-Lozada J, Ahuett-Garza H, Orta-Castañón P, et al. Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing. Addit Manuf, 2019, 26: 227–241

Du Plessis A, Broeckhoven C, Yadroitsava I, et al. Beautiful and functional: A review of biomimetic design in additive manufacturing. Addit Manuf, 2019, 27: 408–427

Galati M, Iuliano L. A literature review of powder-based electron beam melting focusing on numerical simulations. Addit Manuf, 2018, 19: 1–20

Peng X, Kuang X, Roach D J, et al. Integrating digital light processing with direct ink writing for hybrid 3D printing of functional structures and devices. Addit Manuf, 2021, 40: 101911

Aremu A O, Brennan-Craddock J P J, Panesar A, et al. A voxel-based method of constructing and skinning conformal and functionally graded lattice structures suitable for additive manufacturing. Addit Manuf, 2017, 13: 1–13

Liashenko I, Hrynevich A, Dalton P D. Designing outside the box: Unlocking the geometric freedom of melt electrowriting using microscale layer shifting. Adv Mater, 2020, 32: 2001874

Habib M A, Wu S, Fan Q, et al. Bioinspired in situ repeatable self-recovery of superhydrophobicity by self-reconstructing the hierarchical surface structure. Chem Commun, 2021, 57: 8425–8428

Zhang F, Zhu L, Li Z, et al. The recent development of vat photo-polymerization: A review. Addit Manuf, 2021, 48: 102423

Hafkamp T, van Baars G, de Jager B, et al. Real-time feedback controlled conversion in vat photopolymerization of ceramics: A proof of principle. Addit Manuf, 2019, 30: 100775

Cao J, Idrees M, Tian G, et al. Complex SiC-based structures with high specific strength fabricated by vat photopolymerization and one-step pyrolysis. Addit Manuf, 2021, 48: 102430

Liashenko I, Rosell-Llompart J, Cabot A. Ultrafast 3D printing with submicrometer features using electrostatic jet deflection. Nat Commun, 2020, 11: 753

Ligon S C, Liska R, Stampfl J, et al. Polymers for 3D printing and customized additive manufacturing. Chem Rev, 2017, 117: 10212–10290

Paolini A, Kollmannsberger S, Rank E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit Manuf, 2019, 30: 100894

Wu H, Fahy W P, Kim S, et al. Recent developments in polymers/polymer nanocomposites for additive manufacturing. Prog Mater Sci, 2020, 111: 100638

Brenken B, Barocio E, Favaloro A, et al. Fused filament fabrication of fiber-reinforced polymers: A review. Addit Manuf, 2018, 21: 1–16

Gao X, Qi S, Kuang X, et al. Fused filament fabrication of polymer materials: A review of interlayer bond. Addit Manuf, 2021, 37: 101658

Highley C B, Rodell C B, Burdick J A. Direct 3D printing of shear-thinning hydrogels into self-healing hydrogels. Adv Mater, 2015, 27: 5075–5079

Valentine A D, Busbee T A, Boley J W, et al. Hybrid 3D printing of soft electronics. Adv Mater, 2017, 29: 1703817

Kokkinis D, Schaffner M, Studart A R. Multimaterial magnetically assisted 3D printing of composite materials. Nat Commun, 2015, 6: 8643

Skylar-Scott M A, Mueller J, Visser C W, et al. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature, 2019, 575: 330–335

Wallin T J, Pikul J, Shepherd R F. 3D printing of soft robotic systems. Nat Rev Mater, 2018, 3: 84–100

Zhao S, Siqueira G, Drdova S, et al. Additive manufacturing of silica aerogels. Nature, 2020, 584: 387–392

Mostafaei A, Elliott A M, Barnes J E, et al. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog Mater Sci, 2021, 119: 100707

Ziaee M, Crane N B. Binder jetting: A review of process, materials, and methods. Addit Manuf, 2019, 28: 781–801

Tan L J, Zhu W, Zhou K. Recent progress on polymer materials for additive manufacturing. Adv Funct Mater, 2020, 30: 2003062

Lakhdar Y, Tuck C, Binner J, et al. Additive manufacturing of advanced ceramic materials. Prog Mater Sci, 2021, 116: 100736

Li B, Zheng H, Han C, et al. Nanotwins-containing microstructure and superior mechanical strength of a Cu-9Al-5Fe-5Ni alloy additively manufactured by laser metal deposition. Addit Manuf, 2021, 39: 101825

Li B, Han C, Lim C W J, et al. Interface formation and deformation behaviors of an additively manufactured nickel-aluminum-bronze/15-5 PH multimaterial via laser-powder directed energy deposition. Mater Sci Eng-A, 2022, 829: 142101

Fieber L, Evans J D, Huang C, et al. Single-operation, multi-phase additive manufacture of electro-chemical double layer capacitor devices. Addit Manuf, 2019, 28: 344–353

Roach D J, Hamel C M, Dunn C K, et al. The m4 3D printer: A multi-material multi-method additive manufacturing platform for future 3D printed structures. Addit Manuf, 2019, 29: 100819

Wang Y B, Zheng P, Peng T, et al. Smart additive manufacturing: Current artificial intelligence-enabled methods and future perspectives. Sci China Tech Sci, 2020, 63: 1600–1611

Deckard C R. Method and apparatus for producing parts by selective sintering. US Patent. US5017753 A, 1989

Li X, Sheng X, Guo Y, et al. Multifunctional HDPE/CNTs/PW composite phase change materials with excellent thermal and electrical conductivities. J Mater Sci Tech, 2021, 86: 171–179

Liu Z, Yao Y, Wu H. Numerical modeling for solid-liquid phase change phenomena in porous media: Shell-and-tube type latent heat thermal energy storage. Appl Energy, 2013, 112: 1222–1232

Sing S L, Huang S, Goh G D, et al. Emerging metallic systems for additive manufacturing: In-situ alloying and multi-metal processing in laser powder bed fusion. Prog Mater Sci, 2021, 119: 100795

Chen P, Cai H, Li Z, et al. Crystallization kinetics of poly-etheretherketone during high temperature-selective laser sintering. Addit Manuf, 2020, 36: 101615

Author information

Authors and Affiliations

Corresponding authors

Additional information

Supporting Information

The supporting information is available online at https://tech.scichina.com and https://link.springer.com. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

This work was supported by the National Natural Science Foundation of China Aerospace Advanced Manufacturing Technology Research Joint Fund (Grant No. U2037203, 2020) and the Fundamental Research Funds for the Central Universities (Grant No. YCJJ202202010). This project was supported by the State Key Laboratory of Materials Processing and Die & Mould Technology and Analysis and Testing Center, Huazhong University of Science and Technology.

Supporting Information for

Supplementary material, approximately 7.19 MB.

Rights and permissions

About this article

Cite this article

Liu, Z., Li, Z., Wang, Q. et al. Multimaterial additive manufacturing manipulator for fabricating magnetoelectric pressure sensors. Sci. China Technol. Sci. 65, 2542–2550 (2022). https://doi.org/10.1007/s11431-022-2154-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2154-9