Abstract

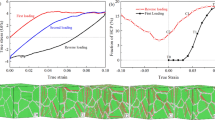

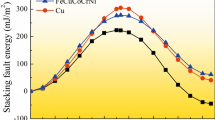

Non-equiatomic FeMnCoCr high-entropy alloy (HEA), which exhibits a great potential to break the strength-ductility trade-off relationship, has drawn abundant attention from researchers in experiments. However, atomic simulations of such excellent alloys are limited due to the lack of proper interatomic potentials. In this work, the complete martensitic transformation of non-equiatomic HEA is reproduced via atomic simulations with a novel interatomic potential under EAM framework. The physical parameters of interatomic potential agree well with experimental measurements and first-principles calculations. According to the atomic simulation results of poly-crystalline under tension and compression, two basic transition models of TRIP-DP-HEA for martensitic transformation are revealed, i.e., the overlapping of intrinsic stacking faults or the growth of hcp laminates simultaneously. Moreover, the pathway for martensitic transformation is elucidated with the gliding of Shockley partial dislocations of 1/6 ❬112❭ burgers vectors.

Similar content being viewed by others

References

Yeh J W, Chen S K, Lin S J, et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv Eng Mater, 2004, 6: 299–303

Otto F, Yang Y, Bei H, et al. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater, 2013, 61: 2628–2638

Gludovatz B, Hohenwarter A, Catoor D, et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science, 2014, 345: 1153–1158

He J Y, Liu W H, Wang H, et al. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater, 2014, 62: 105–113

Miracle D B, Senkov O N. A critical review of high entropy alloys and related concepts. Acta Mater, 2017, 122: 448–511

Li Z, Pradeep K G, Deng Y, et al. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature, 2016, 534: 227–230

Li Z, Tasan C C, Pradeep K G, et al. A TRIP-assisted dual-phase high-entropy alloy: Grain size and phase fraction effects on deformation behavior. Acta Mater, 2017, 131: 323–335

Li Z, Raabe D. Influence of compositional inhomogeneity on mechanical behavior of an interstitial dual-phase high-entropy alloy. Mater Chem Phys, 2018, 210: 29–36

Niendorf T, Wegener T, Li Z, et al. Unexpected cyclic stress-strain response of dual-phase high-entropy alloys induced by partial reversibility of deformation. Scripta Mater, 2018, 143: 63–67

Guo S, Chen H, Wang M. Research on the dislocation differences of CoCrFeMnNi with different local chemical orders during room temperature tensile test. J Alloys Compd, 2021, 868: 159215

Cui Y, Toku Y, Kimura Y, et al. High-strain-rate void growth in high entropy alloys: Suppressed dislocation emission = suppressed void growth. Scripta Mater, 2020, 185: 12–18

Mohammadzadeh R, Mohammadzadeh M. Inverse grain size effect on twinning in nanocrystalline TWIP steel. Mater Sci Eng-A, 2019, 747: 265–275

Meyer R, Entel P. Martensite-austenite transition and phonon dispersion curves of Fe1−xNix studied by molecular-dynamics simulations. Phys Rev B, 1998, 57: 5140

Sak-Saracino E, Urbassek H M. Temperature-induced phase transformation of Fe1−xNix alloys: Molecular-dynamics approach. Eur Phys J B, 2015, 88: 169

Holm A, Mayr S G. Thermal and structural properties of the martensitic transformations in Fe7Pd3 shape memory alloys: An ab initio-based molecular dynamics study. New J Phys, 2019, 21: 063007

Choi W M, Jo Y H, Sohn S S, et al. Understanding the physical metallurgy of the CoCrFeMnNi high-entropy alloy: An atomistic simulation study. npj Comput Mater, 2018, 4: 1

Zhang H F, Yan H L, Fang F, et al. Orientation-dependent mechanical responses and plastic deformation mechanisms of FeMnCoCrNi high-entropy alloy: A molecular dynamics study. Acta Metall Sin (Engl Lett), 2021, 34: 1511–1526

Wang P, Xu S, Liu J, et al. Atomistic simulation for deforming complex alloys with application toward TWIP steel and associated physical insights. J Mech Phys Solids, 2017, 98: 290–308

Liu S, Wei Y. The Gaussian distribution of lattice size and atomic level heterogeneity in high entropy alloys. Extreme Mech Lett, 2017, 11: 84–88

Wang P, Wang H. Meta-atom molecular dynamics for studying material property dependent deformation mechanisms of alloys. J Appl Mech, 2017, 84: 111002

Wang P, Wu Y, Liu J, et al. Impacts of atomic scale lattice distortion on dislocation activity in high-entropy alloys. Extreme Mech Lett, 2017, 17: 38–42

Mohammadzadeh R. Reversible deformation in nanocrystalline TWIP steel during cyclic loading by partial slip reversal and detwinning. Mater Sci Eng-A, 2020, 782: 139251

Wang P, Bu Y, Liu J, et al. Atomic deformation mechanism and interface toughening in metastable high entropy alloy. Mater Today, 2020, 37: 64–73

Ding Q, Zhang Y, Chen X, et al. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature, 2019, 574: 223–227

Li Z. Interstitial equiatomic CoCrFeMnNi high-entropy alloys: carbon content, microstructure, and compositional homogeneity effects on deformation behavior. Acta Mater, 2019, 164: 400–412

Bellaiche L, Vanderbilt D. Virtual crystal approximation revisited: Application to dielectric and piezoelectric properties of perovskites. Phys Rev B, 2000, 61: 7877–7882

Giannozzi P, Baroni S, Bonini N, et al. Quantum espresso: A modular and open-source software project for quantum simulations of materials. J Phys-Condens Matter, 2009, 21: 395502

Rappe A M, Rabe K M, Kaxiras E, et al. Optimized pseudopotentials. Phys Rev B, 1990, 41: 1227–1230

Perdew J P, Burke K, Ernzerhof M. Generalized gradient approximation made simple. Phys Rev Lett, 1996, 77: 3865–3868

Plimpton S. Fast parallel algorithms for short-range molecular dynamics. J Comput Phys, 1995, 117: 1–19

Evans D J, Holian B L. The Nose-Hoover thermostat. J Chem Phys, 1985, 83: 4069–4074

Stukowski A. Visualization and analysis of atomistic simulation data with OVITO—the Open Visualization Tool. Model Simul Mater Sci Eng, 2009, 18: 015012

Faken D, Jónsson H. Systematic analysis of local atomic structure combined with 3D computer graphics. Comput Mater Sci, 1994, 2: 279–286

Bu Y, Li Z, Liu J, et al. Nonbasal slip systems enable a strong and ductile hexagonal-close-packed high-entropy phase. Phys Rev Lett, 2019, 122: 075502

Medvedeva N I, Park M S, Van Aken D C, et al. First-principles study of Mn, Al and C distribution and their effect on stacking fault energies in fcc Fe. J Alloys Compd, 2014, 582: 475–482

Fang Q, Chen Y, Li J, et al. Probing the phase transformation and dislocation evolution in dual-phase high-entropy alloys. Int J Plast, 2019, 114: 161–173

Mizuno M, Sugita K, Araki H. Defect energetics for diffusion in CrMnFeCoNi high-entropy alloy from first-principles calculations. Comput Mater Sci, 2019, 170: 109163

Aguilar-Hurtado J Y, Vargas-Uscategui A, Paredes-Gil K, et al. Boron addition in a non-equiatomic Fe50Mn30Co10Cr10 alloy manufactured by laser cladding: Microstructure and wear abrasive resistance. Appl Surf Sci, 2020, 515: 146084

Bain E C, Dunkirk N Y. The nature of martensite. Trans AIME, 1924, 70: 25–47

Grässel O, Krüger L, Frommeyer G, et al. High strength Fe-Mn-(Al, Si) TRIP/TWIP steels development-properties-application. Int J Plast, 2000, 16: 1391–1409

Wang Y, Liu B, Yan K, et al. Probing deformation mechanisms of a FeCoCrNi high-entropy alloy at 293 and 77 K using in situ neutron diffraction. Acta Mater, 2018, 154: 79–89

Curtze S, Kuokkala V T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater, 2010, 58: 5129–5141

Hill R. The elastic behaviour of a crystalline aggregate. Proc Phys Soc A, 1952, 65: 349–354

Landau L D, Lifshits E M. Course of Theorical Physics: Theory of Elasticity. Oxford: Pergamon Press, 1986

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11902185, 51702207, and 11972219), the Shanghai Sailing Program (Grant No. 19YF1415100), the Young Elite Scientist Sponsorship Program by CAST (Grant No. 2019QNRC001), the Key Research Project of Zhejiang Laboratory, and the Program for Professor of Special Appointment (Young Eastern Scholar Program) at Shanghai Institutions of Higher Learning.

Supporting Information

The supporting information is available online at https://tech.scichina.com and https://link.springer.com. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

Rights and permissions

About this article

Cite this article

Wang, P., Lin, Y., Cao, Y. et al. Atomistic simulations of martensitic transformation processes for metastable FeMnCoCr high-entropy alloy. Sci. China Technol. Sci. 66, 998–1006 (2023). https://doi.org/10.1007/s11431-022-2146-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2146-9