Abstract

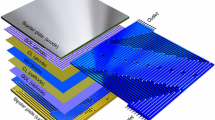

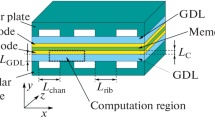

The flow field structure on the bipolar plate significantly affects the performance of the proton exchange membrane electrolysis cell (PEMEC). This paper proposes a new interdigitated-jet hole flow field (JHFF) design to improve the uniformities of liquid saturation, temperature, and current density distributions. The common single-path serpentine flow field (SSFF) and inter-digitated flow field (IFF) are used as comparative references to constitute three PEMEC cases. An advanced numerical model has been established to simulate the performance of the PEMEC using CFD software. The results show that, due to the perpendicular mainstream and the pressure difference, the JHFF enhances the mass and heat transfer inside the porous electrode by introducing strong forced convection, which promotes gas removal underneath the ribs and cooling. Compared with the comparative flow fields, the uniformities of liquid saturation, temperature, and current density distributions by using the JHFF at the anode side are increased by 19.1%, 53.2%, and 40.4%, respectively. Further, mainly owing to the largest conductive area, the PEMEC with the JHFF has superior polarization performance, which is 8.05% higher than the PEMEC with the SSFF.

Similar content being viewed by others

References

Baykara S Z. Hydrogen: A brief overview on its sources, production and environmental impact. Int J Hydrogen Energy, 2018, 43: 10605–10614

Shiva Kumar S, Himabindu V. Hydrogen production by PEM water electrolysis — A review. Mater Sci Energy Technol, 2019, 2: 442–454

Olivier P, Bourasseau C, Bouamama P B. Low-temperature electrolysis system modelling: A review. Renew Sustain Energy Rev, 2017, 78: 280–300

Nitsch J, Klaiss H, Meyer J. The contribution of hydrogen in the development of renewable energy sources. Int J Hydrogen Energy, 1992, 17: 651–663

Carmo M, Fritz D L, Mergel J, et al. A comprehensive review on PEM water electrolysis. Int J Hydrogen Energy, 2013, 38: 4901–4934

Rashid M, Mesfer M K A, Naseem H, et al. Hydrogen production by water electrolysis: A review of alkaline water electrolysis, PEM water electrolysis and high temperature water electrolysis. Int J Eng Adv Technol, 2015, 4: 80–93

Li H, Qi R, Zhang L. Analysis and optimization of material physical characteristics for electrolytic air dehumidifier with a PEM. Appl Thermal Eng, 2020, 169: 114929

Hernández-Gómez Á, Ramirez V, Guilbert D. Investigation of PEM electrolyzer modeling: Electrical domain, efficiency, and specific energy consumption. Int J Hydrogen Energy, 2020, 45: 14625–14639

Nami H, Akrami E, Ranjbar F. Hydrogen production using the waste heat of Benchmark pressurized Molten carbonate fuel cell system via combination of organic Rankine cycle and proton exchange membrane (PEM) electrolysis. Appl Thermal Eng, 2017, 114: 631–638

Li X, Sabir I. Review of bipolar plates in PEM fuel cells: Flow-field designs. Int J Hydrogen Energy, 2005, 30: 359–371

Ojong E T, Kwan J T H, Nouri-Khorasani A, et al. Development of an experimentally validated semi-empirical fully-coupled performance model of a PEM electrolysis cell with a 3-D structured porous transport layer. Int J Hydrogen Energy, 2017, 42: 25831–25847

Nie J, Chen Y, Cohen S, et al. Numerical and experimental study of three-dimensional fluid flow in the bipolar plate of a PEM electrolysis cell. Int J Thermal Sci, 2009, 48: 1914–1922

Nie J, Chen Y. Numerical modeling of three-dimensional two-phase gas-liquid flow in the flow field plate of a PEM electrolysis cell. Int J Hydrogen Energy, 2010, 35: 3183–3197

Tijani A S, Barr D, Rahim A H A. Computational modelling of the flow field of an electrolyzer system using CFD. Energy Procedia, 2015, 79: 195–203

Lee B, Park K, Kim H-M. Dynamic simulation of PEM water electrolysis and comparison with experiments. Int J Electrochem Sci, 2013, 8: 235–248

Minnaar C, De Beer F, Bessarabov D. Current density distribution of electrolyzer flow fields: In situ current mapping and neutron radiography. Energy Fuels, 2020, 34: 1014–1023

Olesen A C, Rømer C, Kær S K. A numerical study of the gas-liquid, two-phase flow maldistribution in the anode of a high pressure PEM water electrolysis cell. Int J Hydrogen Energy, 2016, 41: 52–68

Olesen A C, Frensch S H, Kær S K. Towards uniformly distributed heat, mass and charge: A flow field design study for high pressure and high current density operation of PEM electrolysis cells. Electrochim Acta, 2019, 293: 476–495

Lafmejani S S, Olesen A C, Kær S K. VOF modelling of gas-liquid flow in PEM water electrolysis cell micro-channels. Int J Hydrogen Energy, 2017, 42: 16333–16344

Ito H, Maeda T, Nakano A, et al. Effect of flow regime of circulating water on a proton exchange membrane electrolyzer. Int J Hydrogen Energy, 2010, 35: 9550–9560

Upadhyay M, Lee S, Jung S, et al. Systematic assessment of the anode flow field hydrodynamics in a new circular PEM water electrolyser. Int J Hydrogen Energy, 2020, 45: 20765–20775

Toghyani S, Afshari E, Baniasadi E, et al. Thermal and electrochemical analysis of different flow field patterns in a PEM electrolyzer. Electrochim Acta, 2018, 267: 234–245

Majasan J O, Cho J I S, Dedigama I, et al. Two-phase flow behaviour and performance of polymer electrolyte membrane electrolysers: Electrochemical and optical characterisation. Int J Hydrogen Energy, 2018, 43: 15659–15672

Tugirumubano A, Shin H J, Go S H, et al. Electrochemical performance analysis of a PEM water electrolysis with cathode feed mode based on flow passage shape of titanium plates. Int J Precis Eng Manuf, 2016, 17: 1073–1078

Toghyani S, Afshari E, Baniasadi E. Metal foams as flow distributors in comparison with serpentine and parallel flow fields in proton exchange membrane electrolyzer cells. Electrochim Acta, 2018, 290: 506–519

Tugirumubano A, Kim K S, Shin H J, et al. The design and performance study of polymer electrolyte membrane using 3-D mesh. Key Eng Mater, 2017, 737: 393–397

Toghyani S, Afshari E, Baniasadi E. Three-dimensional computational fluid dynamics modeling of proton exchange membrane electrolyzer with new flow field pattern. J Therm Anal Calorim, 2019, 135: 1911–1919

Ju X, Xu C, Zhou Y, et al. Numerical investigation of a novel manifold micro-pin-fin heat sink combining chessboard nozzle-jet concept for ultra-high heat flux removal. Int J Heat Mass Transfer, 2018, 126: 1206–1218

Siddiqui O, Ishaq H, Chehade G, et al. Experimental investigation of an integrated solar powered clean hydrogen to ammonia synthesis system. Appl Thermal Eng, 2020, 176: 115443

Abdol Rahim A H, Tijani A S, Kamarudin S K, et al. An overview of polymer electrolyte membrane electrolyzer for hydrogen production: Modeling and mass transport. J Power Sources, 2016, 309: 56–65

Han B, Steen III S M, Mo J, et al. Electrochemical performance modeling of a proton exchange membrane electrolyzer cell for hydrogen energy. Int J Hydrogen Energy, 2015, 40: 7006–7016

Abdin Z, Webb C J, Gray E M A. Modelling and simulation of a proton exchange membrane (PEM) electrolyser cell. Int J Hydrogen Energy, 2015, 40: 13243–13257

Wang Z M, Xu C, Wang X Y, et al. Numerical investigation of water and temperature distributions in a proton exchange membrane electrolysis cell. Sci China Tech Sci, 2021, 64: 1555–1566

Wang Y, Wang S, Liu S, et al. Three-dimensional simulation of a PEM fuel cell with experimentally measured through-plane gas effective diffusivity considering Knudsen diffusion and the liquid water effect in porous electrodes. Electrochim Acta, 2019, 318: 770–782

Yi X, Ye F, Guo H, Ma C. Two-dimensional numerical simulation of transient response of two-phase heat and mass transfer in a proton exchange membrane electrolyzer cell. Sustain Energy, 2018, 8: 10–22

Falcão D S, Pinto A M F R. A review on PEM electrolyzer modelling: Guidelines for beginners. J Clean Prod, 2020, 261: 121184

Zhang Z, Xing X. Simulation and experiment of heat and mass transfer in a proton exchange membrane electrolysis cell. Int J Hydrogen Energy, 2020, 45: 20184–20193

Han B, Mo J, Kang Z, et al. Modeling of two-phase transport in proton exchange membrane electrolyzer cells for hydrogen energy. Int J Hydrogen Energy, 2017, 42: 4478–4489

Miao Z, He Y L, Li X L, et al. A two-dimensional two-phase mass transport model for direct methanol fuel cells adopting a modified agglomerate approach. J Power Sources, 2008, 185: 1233–1246

Möckl M, Bernt M, Schröter J, et al. Proton exchange membrane water electrolysis at high current densities: Investigation of thermal limitations. Int J Hydrogen Energy, 2020, 45: 1417–1428

Olesen A C, Kær S K. Flow maldistribution in the anode of a polymer electrolyte membrane water electrolysis cell employing interdigitated channels. In: Proceedings of the 55th International Conference on Simulation and Modelling. Aalborg, 2014

Mo J, Kang Z, Yang G, et al. In situ investigation on ultrafast oxygen evolution reactions of water splitting in proton exchange membrane electrolyzer cells. J Mater Chem A, 2017, 5: 18469–18475

Chandesris M, Médeau V, Guillet N, et al. Membrane degradation in PEM water electrolyzer: Numerical modeling and experimental evidence of the influence of temperature and current density. Int J Hydrogen Energy, 2015, 40: 1353–1366

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51821004 and 52090062) and the research project from China Three Gorges Corporation (Contract No. 202003346).

Rights and permissions

About this article

Cite this article

Wang, X., Wang, Z., Feng, Y. et al. Three-dimensional multiphase modeling of a proton exchange membrane electrolysis cell with a new interdigitated-jet hole flow field. Sci. China Technol. Sci. 65, 1179–1192 (2022). https://doi.org/10.1007/s11431-022-2026-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2026-6