Abstract

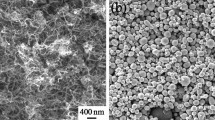

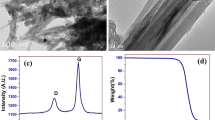

The raw and pre-smashed (PS) carbon nanotube (CNT) reinforced 6061Al composites (CNT/6061Al) with different CNT contents were respectively fabricated by powder metallurgy technology. It was found that reducing the CNT cluster size by pre-smashing processing could sharply reduce the friction coefficient, and significantly improve the density, hardness, and wear resistance of the CNT/6061Al composites. For the raw-CNT/6061Al composites, the wear rate increased approximately linear trend while the CNT content was over 1 wt.%. The plastic deformation, deep grooves, and serious delamination were presented on the wear surface. The wear process was gradually transformed from Al-copper base counterpart wear into Al-Al wear for the higher adhesion-binding energy between aluminum and copper base counterpart. While for the PS-CNT/6061Al composites, the wear rate gradually decreased as the CNT content increased from 0 to 2 wt.%. This was mainly because the generation of the thinner mechanically mixed layer (MML) and the PS-CNT prevented the direct contact between specimen and copper base counterpart, which effectively inhibited the adhesive wear. But excessive PS-CNT addition (∼3 wt.%) would weaken the bonding between CNT and 6061Al, and thus the wear resistance of the composite was reduced apparently.

Similar content being viewed by others

References

Xiao B L, Huang Z Y, Ma K, et al. Research on hot deformation behaviors of discontinuously reinforced aluminum composites. Acta Metall Sin, 2019, 55: 59–72

Zan Y N, Zhou Y T, Liu Z Y, et al. Enhancing strength and ductility synergy through heterogeneous structure design in nanoscale Al2O3 particulate reinforced Al composites. Mater Des, 2019, 166: 107629

Zan Y N, Zhou Y T, Li X N, et al. Enhancing high-temperature strength and thermal stability of Al2O3/Al composites by high-temperature pre-treatment of ultrafine Al powders. Acta Metall Sin (Engl Lett), 2020, 33: 913–921

Miyajima T, Iwai Y. Effects of reinforcements on sliding wear behavior of aluminum matrix composites. Wear, 2003, 255: 606–616

Zhou L, Cui C, Wang Q Z, et al. Constitutive equation and model validation for a 31 vol.% B4Cp/6061Al composite during hot compression. J Mater Sci Tech, 2018, 34: 1730

Bakshi S R, Lahiri D, Agarwal A. Carbon nanotube reinforced metal matrix composites—A review. Int Mater Rev, 2013, 55: 41–64

Singla D, Amulya K, Murtaza Q. CNT reinforced aluminium matrix composite—A review. Mater Today-Proc, 2015, 2: 2886–2895

Tjong S C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater Sci Eng-R-Rep, 2013, 74: 281–350

Choi H, Kwon G, Lee G, et al. Reinforcement with carbon nanotubes in aluminum matrix composites. Scripta Mater, 2008, 59: 360–363

Akhlaghi F, Zare-Bidaki A. Influence of graphite content on the dry sliding and oil impregnated sliding wear behavior of Al 2024-graphite composites produced by in situ powder metallurgy method. Wear, 2009, 266: 37–45

Zhao K, Liu Z Y, Xiao B L, et al. Origin of insignificant strengthening effect of CNTs in T6-treated CNT/6061Al composites. Acta Metall Sin (Engl Lett), 2017, 31: 134–142

Zhang X X, Zhang J F, Liu Z Y, et al. Microscopic stresses in carbon nanotube reinforced aluminum matrix composites determined by in-situ neutron diffraction. J Mater Sci Tech, 2020, 54: 58–68

Nam D H, Kim J H, Cha S I, et al. Hardness and wear resistance of carbon nanotube reinforced aluminum-copper matrix composites. J Nanosci Nanotechnol, 2014, 14: 9134–9138

Bakshi S R, Agarwal A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites. Carbon, 2011, 49: 533–544

Zhou S, Zhang X, Ding Z, et al. Fabrication and tribological properties of carbon nanotubes reinforced Al composites prepared by pressureless infiltration technique. Compos Part A-Appl Sci Manuf, 2007, 38: 301–306

Bastwros M M H, Esawi A M K, Wifi A. Friction and wear behavior of Al−CNT composites. Wear, 2013, 307: 164–173

Kim I Y, Lee J H, Lee G S, et al. Friction and wear characteristics of the carbon nanotube-aluminum composites with different manufacturing conditions. Wear, 2009, 267: 593–598

Chen W X, Tu J P, Wang L Y, et al. Tribological application of carbon nanotubes in a metal-based composite coating and composites. Carbon, 2003, 41: 215–222

Al-Qutub A M, Khalil A, Saheb N, et al. Wear and friction behavior of Al6061 alloy reinforced with carbon nanotubes. Wear, 2013, 297: 752–761

Pérez-Bustamante R, Bueno-Escobedo J L, Jiménez-Lobato J, et al. Wear behavior in Al2024-CNTs composites synthesized by mechanical alloying. Wear, 2012, 292–293: 169–175

Choi H J, Lee S M, Bae D H. Wear characteristic of aluminum-based composites containing multi-walled carbon nanotubes. Wear, 2010, 270: 12–18

Suzuki T, Kato M, Saito H, et al. Effect of carbon nanotube (CNT) size on wear properties of Cu-based CNT composite electrodes in electrical discharge machining. JMMP, 2011, 5: 348–359

Sundaram R, Yamada T, Hata K, et al. Electrical performance of lightweight CNT−Cu composite wires impacted by surface and internal Cu spatial distribution. Sci Rep, 2017, 7: 9267

Liu Z Y, Ma K, Fan G H, et al. Enhancement of the strength-ductility relationship for carbon nanotube/Al−Cu−Mg nanocomposites by material parameter optimisation. Carbon, 2020, 157: 602–613

Liu Z Y, Zhao K, Xiao B L, et al. Fabrication of CNT/Al composites with low damage to CNTs by a novel solution-assisted wet mixing combined with powder metallurgy processing. Mater Des, 2016, 97: 424–430

Jiang J L, Wang H Z, Yang H, et al. Fabrication and wear behavior of CNT/Al composites. Trans Nonferr Metals Soc China, 2007, 17: 113–116

Yildirim M, Özyürek D, Gürü M. Investigation of microstructure and wear behaviors of al matrix composites reinforced by carbon nanotube. Fullerenes Nanotubes Carbon Nanostruct, 2016, 24: 467–473

Idusuyi N, Olayinka J I. Dry sliding wear characteristics of aluminium metal matrix composites: A brief overview. J Mater Res Tech, 2019, 8: 3338–3346

Morsi K, Esawi A. Effect of mechanical alloying time and carbon nanotube (CNT) content on the evolution of aluminum (Al)-CNT composite powders. J Mater Sci, 2007, 42: 4954–4959

Liu Z Y, Xu S J, Xiao B L, et al. Effect of ball-milling time on mechanical properties of carbon nanotubes reinforced aluminum matrix composites. Compos Part A-Appl Sci Manuf, 2012, 43: 2161–2168

Liu Z Y, Xiao B L, Wang W G, et al. Analysis of carbon nanotube shortening and composite strengthening in carbon nanotube/aluminum composites fabricated by multi-pass friction stir processing. Carbon, 2014, 69: 264–274

Liu Z Y, Xiao B L, Wang W G, et al. Tensile strength and electrical conductivity of carbon nanotube reinforced aluminum matrix composites fabricated by powder metallurgy combined with friction stir processing. J Mater Sci Tech, 2014, 30: 649–655

Ramesh C S, Keshavamurthy R, Koppad P G, et al. Role of particle stimulated nucleation in recrystallization of hot extruded Al 6061/SiCp composites. Trans Nonferrous Met Soc China, 2013, 23: 53–58

Wang L Y, Tu J P, Chen W X, et al. Friction and wear behavior of electroless Ni-based CNT composite coatings. Wear, 2003, 254: 1289–1293

Liu Y B, Lim S C, Ray S, et al. Friction and wear of aluminium-graphite composites: The smearing process of graphite during sliding. Wear, 1992, 159: 201–205

Vijh A K. The influence of metal-metal bond energies on the adhesion, hardness, friction and wear of metals. J Mater Sci, 1975, 10: 998–1004

He H, Hahn S H, Yu J, et al. Friction-induced subsurface densification of glass at contact stress far below indentation damage threshold. Acta Mater, 2020, 189: 166–173

Pashley M D, Pethica J B, Tabor D. Adhesion and micromechanical properties of metal surfaces. Wear, 1984, 100: 7–31

Derjaguin B V, Smilga V P. Electronic theory of adhesion. J Appl Phys, 1967, 38: 4609–4616

Kayaba T, Kato K. Wear of Materials. New York: ASME, 1979. 45

Rigney D A, Chen L H, Naylor M G S, et al. Wear processes in sliding systems. Wear, 1984, 100: 195–219

Chen L H, Rigney D A. Transfer during unlubricated sliding wear of selected metal systems. Wear, 1985, 105: 47–61

Tabor D. Surface forces and surface interactions. J Colloid Interface Sci, 1977, 58: 2–13

Pei Y T, Galvan D, De Hosson J T M. Nanostructure and properties of TiC/a-C:H composite coatings. Acta Mater, 2005, 53: 4505–4521

Venkataraman B, Sundararajan G. Correlation between the characteristics of the mechanically mixed layer and wear behaviour of aluminium, Al-7075 alloy and Al−MMCs. Wear, 2000, 245: 22–38

Lee T, Lee J, Lee D, et al. Effects of particle size and surface modification of SiC on the wear behavior of high volume fraction Al/SiCp composites. J Alloys Compd, 2020, 831: 154647

Hassan A M, Mayyas A T, Alrashdan A, et al. Wear behavior of Al−Cu and Al−Cu/SiC components produced by powder metallurgy. J Mater Sci, 2008, 43: 5368–5375

Zhang J, Alpas A T. Transition between mild and severe wear in aluminium alloys. Acta Mater, 1997, 45: 513–528

Yin C, Liang Y, Liang Y, et al. Formation of a self-lubricating layer by oxidation and solid-state amorphization of nano-lamellar microstructures during dry sliding wear tests. Acta Mater, 2019, 166: 208–220

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Key R&D Program of China (Grant No. 2017YFB0703104), the Key Research Program of Frontier Sciences, CAS (Grant No. QYZDJ-SSW-JSC015), the National Natural Science Foundation of China (Grant Nos. 51931009, 51871214, 51871215), and the Youth Innovation Promotion Association CAS (Grant No. 2020197).

Rights and permissions

About this article

Cite this article

Li, X., Liu, Z., Zan, Y. et al. Wear behavior of the raw and pre-smashed carbon nanotubes reinforced 6061Al composites fabricated by powder metallurgy. Sci. China Technol. Sci. 65, 1149–1159 (2022). https://doi.org/10.1007/s11431-020-1817-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1817-3