Abstract

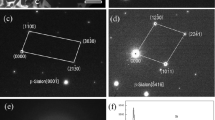

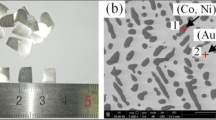

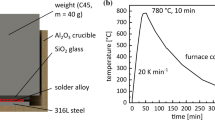

This study focuses on the design, characterization and testing of a novel anorthite based glass-ceramic solder for joining dense Si3N4 and porous Si3N4 ceramic. It was found that the glass solder possesses a favorable wetting ability on two ceramic surfaces. Additionally, the influence of crystallization treatment on the microstructure and shear strength of joints was investigated. The results showed that CaAl2Si2O8 was the main product in the seam. After crystallization treatment, the crystallinitiy of the seam and shear strength of joints were improved obviously. The shear strength of joints after crystallization was 52 MPa at room temperature, and it increased to 59 MPa at 850°C. Finally, the joining mechanism of the dense Si3N4/glass-ceramic/porous Si3N4 bonded joints was proposed. Intergranular diffusion of elements was identified as the main mechanism of bonding in the interface of dense Si3N4/glass-ceramic. In the porous Si3N4 side, the bonding was achieved by infiltration that was controlled by capillarity and resistance of the viscous forces.

Similar content being viewed by others

References

Mazdiyasni K S, West R, David L D. Characterization of organosilicon-infiltrated porous reaction-sintered Si3N4. J Am Ceramic Soc, 1978, 61: 504–508

Yang J F, Zhang G J, Kondo N, et al. Synthesis of porous Si3N4 ceramics with rod-shaped pore structure. J Am Ceramic Soc, 2005, 88: 1030–1032

Xia Y, Zeng Y P, Jiang D. Dielectric and mechanical properties of porous Si3N4 ceramics prepared via low temperature sintering. Ceramics Int, 2009, 35: 1699–1703

Kondo N, Inagaki Y, Suzuki Y, et al. Fabrication of porous anisotropic silicon nitride by using partial sinter-forging technique. Mater Sci Eng-A, 2002, 335: 26–31

Yin S, Pan L, Huang K, et al. Porous Si3N4 ceramics with hierarchical pore structures prepared by gelcasting using DMAA as gelling agent and PS as pore-forming agent. J Alloys Compd, 2019, 805: 69–77

Wang B, Shangguan D, Qiao R, et al. Fabrication, mechanical properties and thermal shock resistance of a dense SiC NWs/α-Si3N4 composite coating for protecting porous Si3N4 ceramics. Ceramics Int, 2019, 45: 23241–23247

Wang C, Qiao R, Chen L. Fabrication and erosion resistance of dense α-Si3N4/Sialon coating on porous Si3 N4 ceramic. RSC Adv, 2016, 6: 63801–63808

Wang C, Fan L, Fan J, et al. Effect of spraying power on microstructure and properties of supersonic plasma sprayed Al2O3 coating on porous Si3N4 substrate. J Alloys Compd, 2013, 559: 152–157

Li X, Zhang L, Yin X. Synthesis, electromagnetic reflection loss and oxidation resistance of pyrolytic carbon-Si3N4 ceramics with dense Si3N4 coating. J Eur Ceramic Soc, 2012, 32: 1485–1489

Chen Y C, Iwamoto C, Ishida Y. Chemical behavior in diffusion bonding of Si3N4-Ni and Si3N4-superalloy IN-738. Scripta Mater, 1996, 35: 675–681

Zhao Y, Bian H, Fu W, et al. Laser-induced metallization of porous Si3N4 ceramic and its brazing to TiAl alloy. J Am Ceram Soc, 2019, 102: 32–36

Chaumat G, Drevet B, Vernier L. Reactive brazing study of a silicon nitride to metal joining. J Eur Ceramic Soc, 1997, 17: 1925–1927

Song X, Zhao Y, Hu S, et al. Wetting of AgCu-Ti filler on porous Si3N4 ceramic and brazing of the ceramic to TiAl alloy. Ceramics Int, 2018, 44: 4622–4629

Zhang J, Liu J Y, Wang T P. Microstructure and brazing mechanism of porous Si3N4/Invar joint brazed with Ag-Cu-Ti/Cu/Ag-Cu multi-layered filler. J Mater Sci Tech, 2018, 34: 713–719

Liang H, Guo H, Yin J, et al. The application of Lu-Al-Si-O-N oxynitride glass in transparent AlON ceramics joining. Ceramics Int, 2019, 45: 2591–2595

Jiang C, Lin P, Chen Q, et al. Microstructure and properties of functional magnesium titanate ceramic joint brazed by bismuth-borate glass. J Eur Ceramic Soc, 2019, 39: 4901–4910

Guo W, Fu L, He P, et al. Air-brazed Al2O3 joint with a novel bismuth glass. Ceramics Int, 2019, 45: 15213–15222

Ahmad S, Herrmann M, Mahmoud M M, et al. Application of Nd2O3-Al2O3-SiO2 glass solder for joining of silicon carbide components. J Eur Ceramic Soc, 2016, 36: 1559–1569

Casalegno V, Kondo S, Hinoki T, et al. CaO-Al2O3 glass-ceramic as a joining material for SiC based components: A microstructural study of the effect of Si-ion irradiation. J Nucl Mater, 2018, 501: 172–180

Bocanegra-Bernal M H, Matovic B. Mechanical properties of silicon nitride-based ceramics and its use in structural applications at high temperatures. Mater Sci Eng-A, 2010, 527: 1314–1338

Zhou F, Chen Z. Bonding of silicon nitride ceramic composites with Y2O3-La2O3-Al2O3-SiO2 mixtures. J Mater Res, 2002, 17: 1969–1972

Mecartney M L, Sinclair R, Loehman R E. Silicon nitride joining. J Am Ceramic Soc, 1985, 68: 472–478

Ahn B G, Shiraishi Y. Joining of Si3N4 to Si3N4 with partially crystallized cordierite glass or oxynitride glass solders. High Temp Mater Process, 1998, 17: 245–252

Sainz M A, Miranzo P, Osendi M I. Silicon nitride joining using silica and yttria ceramic interlayers. J Am Ceramic Soc, 2002, 85: 941–946

Li L, Sun L, Liu C, et al. Microstructure and properties of porous Si3N4/dense Si3N4 joints bonded using RE-Si-Al-O-N (RE=Y or Yb) glasses. Metals, 2017, 7: 500

Liang H, Zuo K, Xia Y, et al. Joining of dense Si3N4 ceramics with tape cast Lu-Al-Si-O-N interlayer. Ceramics Int, 2018, 44: 4824–4828

Zhu W, Zhang H, Xue D, et al. Joining alumina ceramic by using glass ceramic filler with high crystallinity for high temperature application. Ceramics Int, 2019, 45: 20999–21003

Kurama S, Ozel E. The influence of different CaO source in the production of anorthite ceramics. Ceramics Int, 2009, 35: 827–830

Knickerbocker S, Tuzzolo M R, Lawhorne S. Sinterable beta-spodumene glass-ceramics. J Am Ceramic Soc, 1989, 72: 1873–1879

Fang J, Sun L, Qi Q, et al. Microstructure evolution and mechanical properties of porous Si3N4 and dense Si3N4 joints bonded using CaO-Li2O-Al2O3-SiO2 glass-ceramic. J Eur Ceramic Soc, 2019, 39: 4545–4553

Lin P, Lin T, He P, et al. Wetting behavior and bonding characteristics of bismuth-based glass brazes used to join Li-Ti ferrite systems. Ceramics Int, 2017, 43: 13530–13540

Serbena F C, Mathias I, Foerster C E, et al. Crystallization toughening of a model glass-ceramic. Acta Mater, 2015, 86: 216–228

Sun L, Liu C, Zhang J, et al. Joining pre-oxidized dense Si3N4 to porous Si3N4 with β-spodumene based glass-ceramic interlayer. Appl Surf Sci, 2019, 481: 515–523

Maeda K, Yasumori A. Toughening of CaO-Al2O3-SiO2 glass by dmisteinbergite precipitation. Mater Lett, 2016, 180: 231–234

Washburn E W. Note on a method of determining the distribution of pore sizes in a porous material. Proc Natl Acad Sci USA, 1921, 7: 115–116

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51872060, 51621091, U1537206), and the Nation Key Research & Development Plan (Grant No. 2017YFA0403804).

Rights and permissions

About this article

Cite this article

Fang, J., Zhang, J., Liu, C. et al. Joining dense Si3N4 to porous Si3N4 by using an anorthite based glass-ceramic. Sci. China Technol. Sci. 63, 1538–1548 (2020). https://doi.org/10.1007/s11431-020-1653-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1653-y