Abstract

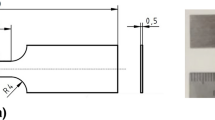

In this study, two Cu-Al-Mn-Fe polycrystalline alloys were prepared, and their microstructure, reversible martensitic transformation, mechanical properties and shape memory effects were investigated. The results show that the reversible martensitic transformation temperatures of the studied alloys are between room temperature and 373 K, which are suitable for practical applications. Two typed martensites of 18R and 2H coexist both in two alloys. The bcc β (FeAl) nanoparticles are Fe-rich, Mn-rich and Cu-poor, whereas the martensite is Cu-rich, Fe-poor and Mn-poor. The size of nanoparticles ranges from tens to hundreds of nanometers. Full shape recovery property is displayed in Cu-12.9Al-4.5Mn-2.6Fe alloy all the time while applying different deformation from 5% to 8%. The maximum recoverable strain is up to 4.4% with a recovery rate of 100%.

Similar content being viewed by others

References

Otsuka K, Wayman C M. Shape Memory Materials. Cambridge University Press, Cambridge, 1998

Pan J, Shi Z Y, Wang T M. Variable-model SMA-driven spherical robot. Sci China Technol Sci, 2019, 62: 1401–1411

Tong Y, Shuitcev A, Zheng Y. Recent development of TiNi-based shape memory alloys with high cycle stability and high transformation temperature. Adv Eng Mater, 2020, 22: 1900496

Sun Q P, Aslan A, Li M P, et al. Effects of grain size on phase transition behavior of nanocrystalline shape memory alloys. Sci China Technol Sci, 2014, 57: 671–679

Zeng J M, Jiang H C, Liu S W, et al. Damping behavior of Ti50.1Ni49.9 alloy in reverse martensitic transformation region. Sci China Technol Sci, 2012, 55: 470–474

Dasgupta R. A look into Cu-based shape memory alloys: Present scenario and future prospects. J Mater Res, 2014, 29: 1681–1698

Omori T, Kusama T, Kawata S, et al. Abnormal grain growth induced by cyclic heat treatment. Science, 2013, 341: 1500–1502

Kusama T, Omori T, Saito T, et al. Ultra-large single crystals by abnormal grain growth. Nat Commun, 2017, 8: 354

Tanaka Y, Himuro Y, Kainuma R, et al. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science, 2010, 327: 1488–1490

Omori T, Ando K, Okano M, et al. Superelastic effect in polycrystalline Ferrous alloys. Science, 2011, 333: 68–71

Omori T, Iwaizako H, Kainuma R. Abnormal grain growth induced by cyclic heat treatment in Fe-Mn-Al-Ni superelastic alloy. Mater Des, 2016, 101: 263–269

Vollmer M, Arold T, Kriegel M J, et al. Promoting abnormal grain growth in Fe-based shape memory alloys through compositional adjustments. Nat Commun, 2019, 10: 2337

Lexcellent C, Goo B C, Sun Q P, et al. Characterization, thermomechanical behaviour and micromechanical-based constitutive model of shape-memory CuZnAl single crystals. Acta Mater, 1996, 44: 3773–3780

Somerday M, Wert J A, Comstock Jr. R J. Effect of grain size on the observed pseudoelastic behavior of a Cu-Zn-Al shape memory alloy. Metall Mat Trans A, 1997, 28: 2335–2341

Arneodo Larochette P, Ahlers M. Grain-size dependence of the two-way shape memory effect obtained by stabilisation in Cu-Zn-Al crystals. Mater Sci Eng-A, 2003, 361: 249–257

Cingolani E, Ahlers M, Sade M. The two way shape memory effect in CuZnAl single crystals: Role of dislocations and stabilization. Acta Metall Mater, 1995, 43: 2451–2461

Otsuka K, Wayman C M, Nakai K, et al. Superelasticity effects and stress-induced martensitic transformations in CuAlNi alloys. Acta Metall, 1976, 24: 207–226

Matlakhova L A, Pereira E C, Matlakhov A N, et al. Mechanical behavior and fracture characterization of a monocrystalline Cu-Al-Ni subjected to thermal cycling treatments under load. Mater Charact, 2008, 59: 1630–1637

Kim J W, Roh D W, Lee E S, et al. Effects on microstructure and tensile properties of a zirconium addition to a Cu-Al-Ni shape memory alloy. MTA, 1990, 21: 741–744

Ibarra A, San Juan J, Bocanegra E H, et al. Evolution of microstructure and thermomechanical properties during superelastic compression cycling in Cu-Al-Ni single crystals. Acta Mater, 2007, 55: 4789–4798

Sutou Y, Omori T, Yamauchi K, et al. Effect of grain size and texture on pseudoelasticity in Cu-Al-Mn-based shape memory wire. Acta Mater, 2005, 53: 4121–4133

Mallik U S, Sampath V. Influence of aluminum and manganese concentration on the shape memory characteristics of Cu-Al-Mn shape memory alloys. J Alloys Compd, 2008, 459: 142–147

Kainuma R, Satoh N, Liu X J, et al. Phase equilibria and Heusler phase stability in the Cu-rich portion of the Cu-Al-Mn system. J Alloys Compd, 1998, 266: 191–200

Kainuma R, Takahashi S, Ishida K. Thermoelastic martensite and shape memory effect in ductile Cu-Al-Mn alloys. MMTA, 1996, 27: 2187–2195

Jiao Z, Wang Q, Yin F, et al. Special corrosion behavior of an inoculant refined Cu-Al-Mn shape memory alloy during electropolishing process. Mater Charact, 2019, 153: 348–353

Sutou Y, Omori T, Kainuma R, et al. Enhancement of superelasticity in Cu-Al-Mn-Ni shape-memory alloys by texture control. Metall Mat Trans A, 2002, 33: 2817–2824

Silva R A G, Gama S, Paganotti A, et al. Effect of Ag addition on phase transitions of the Cu-22.26 at.%Al-9.93 at.%Mn alloy. Therm Acta, 2013, 554: 71–75

Canbay C A, Ozgen S, Genc Z K. Thermal and microstructural investigation of Cu-Al-Mn-Mg shape memory alloys. Appl Phys A, 2014, 117: 767–771

Canbay C A, Genc Z K, Sekerci M. Thermal and structural characterization of Cu-Al-Mn-X (Ti, Ni) shape memory alloys. Appl Phys A, 2014, 115: 371–377

Sutou Y, Kainuma R, Ishida K. Effect of alloying elements on the shape memory properties ofductile Cu-Al-Mn alloys. Mater Sci EngA, 1999, 273–275: 375–379

Mallik U S, Sampath V. Influence of quaternary alloying additions on transformation temperatures and shape memory properties of Cu-Al-Mn shape memory alloy. J Alloys Compd, 2009, 469: 156–163

Chen X, Zhang F, Chi M, et al. Microstructure, superelasticity and shape memory effect by stress-induced martensite stabilization in Cu-Al-Mn-Ti shape memory alloys. Mater Sci Eng-B, 2018, 236–237: 10–17

Yang S, Omori T, Wang C, et al. A jumping shape memory alloy under heat. Sci Rep, 2016, 6: 21754

Yang S, Chi M, Zhang J, et al. Shape memory effect promoted through martensite stabilization induced by the precipitates in Cu-Al-Mn-Fe alloys. Mater Sci Eng-A, 2019, 739: 455–462

Wang C P, Liu X J, Ohnuma I, et al. Thermodynamic database of the phase diagrams in Cu-Fe base ternary systems. J Phs Eqil Diff, 2004, 25: 320–328

Umino R, Liu X J, Sutou Y, et al. Experimental determination and thermodynamic calculation of phase equilibria in the Fe-Mn-Al system. JPED, 2006, 27: 54–62

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant No. 51971185), the Guangdong Basic and Applied Basic Research Foundation (Grant No. 2020A1515010069), the Shenzhen Science and Technology Project (Grant No. JCYJ20190809162401686). We also thank Y. X. Huang, J. B. Zhang, K. B. He and W. Zheng for helping experimental procedures.

Rights and permissions

About this article

Cite this article

Yang, S., Hong, S., Li, M. et al. Microstructure, martensitic transformation and shape memory effect of polycrystalline Cu-Al-Mn-Fe alloys. Sci. China Technol. Sci. 64, 400–406 (2021). https://doi.org/10.1007/s11431-020-1617-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1617-x