Abstract

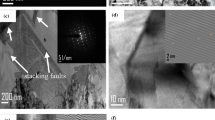

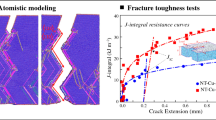

Herein, we fabricated a heterogeneous nanostructured Cu with deformation nanotwin bundles (NTBs) embedded in a matrix of nanograins by means of dynamic plastic deformation at liquid nitrogen temperature. We conducted fracture mechanical measurements to investigate the effect of longitudinal length of the NTBs on their strengthening and toughening. Results suggest that an increase in the NTB length had a marginal influence on the tensile strength; however, it remarkably promoted both fracture initiation toughness and crack growth toughness. Longer NTBs are more effective not only in intrinsically enhancing crack tip plasticity by suppressing the strain localization and void nucleation but also in serving as crack bridges behind the crack front to extrinsically resist the fracture by shielding the crack tip.

Similar content being viewed by others

References

Lu K. The future of metals. Science, 2010, 328: 319–320

Meyers M A, Mishra A, Benson D J. Mechanical properties of na-nocrystalline materials. Prog Mater Sci, 2006, 51: 427–556

Zhu Y T, Liao X. Retaining ductility. Nat Mater, 2004, 3: 351–352

Pippan R, Hohenwarter A. The importance of fracture toughness in ultrafine and nanocrystalline bulk materials. Mater Res Lett, 2016, 4: 127–136

Pineau A, Amine Benzerga A, Pardoen T. Failure of metals III: Fracture and fatigue of nanostructured metallic materials. Acta Mater, 2016, 107: 508–544

Lu K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat Rev Mater, 2016, 1: 16019

Lu K, Lu L, Suresh S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science, 2009, 324: 349–352

Wu X, Zhu Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater Res Lett, 2017, 5: 527–532

Wu X, Yang M, Yuan F, et al. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc Natl Acad Sci USA, 2015, 112: 14501–14505

Wu X L, Jiang P, Chen L, et al. Synergetic strengthening by gradient structure. Mater Res Lett, 2014, 2: 185–191

Lu K. Making strong nanomaterials ductile with gradients. Science, 2014, 345: 1455–1456

Ritchie R O. The conflicts between strength and toughness. Nat Mater, 2011, 10: 817–822

Kumar K S, Suresh S, Chisholm M F, et al. Deformation of electro-deposited nanocrystalline nickel. Acta Mater, 2003, 51: 387–405

Hohenwarter A, Pippan R. Fracture toughness evaluation of ultrafine-grained nickel. Scripta Mater, 2011, 64: 982–985

Luo S, You Z, Lu L. Thickness effect on fracture behavior of columnar-grained Cu with preferentially oriented nanoscale twins. J Mater Res, 2017, 32: 4554–4562

Luo S S, You Z S, Lu L. Intrinsic fracture toughness of bulk nanos-tructured Cu with nanoscale deformation twins. Scripta Mater, 2017, 133: 1–4

You Z S, Lu L, Lu K. Tensile behavior of columnar grained Cu with preferentially oriented nanoscale twins. Acta Mater, 2011, 59: 6927–6937

Shen Y F, Lu L, Lu Q H, et al. Tensile properties of copper with nano-scale twins. Scripta Mater, 2005, 52: 989–994

Lu L, Shen Y, Chen X, et al. Ultrahigh strength and high electrical conductivity in copper. Science, 2004, 304: 422–426

Lu L, You Z S, Lu K. Work hardening of polycrystalline Cu with nanoscale twins. Scripta Mater, 2012, 66: 837–842

Dao M, Lu L, Shen Y F, et al. Strength, strain-rate sensitivity and ductility of copper with nanoscale twins. Acta Mater, 2006, 54: 5421–5432

You Z, Lu L. Deformation and fracture mechanisms of nanotwinned metals. Natl Sci Rev, 2017, 4: 519–521

Shan Z W, Lu L, Minor A M, et al. The effect of twin plane spacing on the deformation of copper containing a high density of growth twins. JOM, 2008, 60: 71–74

Zeng Z, Li X, Lu L, et al. Fracture in a thin film of nanotwinned copper. Acta Mater, 2015, 98: 313–317

Kim S W, Li X, Gao H, et al. In situ observations of crack arrest and bridging by nanoscale twins in copper thin films. Acta Mater, 2012, 60: 2959–2972

Shin Y A, Yin S, Li X, et al. Nanotwin-governed toughening mechanism in hierarchically structured biological materials. Nat Commun, 2016, 7: 10772

Lu K, Yan F K, Wang H T, et al. Strengthening austenitic steels by using nanotwinned austenitic grains. Scripta Mater, 2012, 66: 878–883

Tao N R, Lu K. Nanoscale structural refinement via deformation twinning in face-centered cubic metals. Scripta Mater, 2009, 60: 1039–1043

Li Y S, Tao N R, Lu K. Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater, 2008, 56: 230–241

Bouaziz O, Barbier D, Cugy P, et al. Effect of process parameters on a metallurgical route providing nano-structured single phase steel with high work-hardening. Adv Eng Mater, 2012, 14: 49–51

Zhang Y, Tao N R, Lu K. Mechanical properties and rolling behaviors of nano-grained copper with embedded nano-twin bundles. Acta Mater, 2008, 56: 2429–2440

Qin E W, Lu L, Tao N R, et al. Enhanced fracture toughness and strength in bulk nanocrystalline Cu with nanoscale twin bundles. Acta Mater, 2009, 57: 6215–6225

Qin E W, Lu L, Tao N R, et al. Enhanced fracture toughness of bulk nanocrystalline Cu with embedded nanoscale twins. Scripta Mater, 2009, 60: 539–542

Xiong L, You Z S, Qu S D, et al. Fracture behavior of heterogeneous nanostructured 316L austenitic stainless steel with nanotwin bundles. Acta Mater, 2018, 150: 130–138

Xiong L, You Z S, Lu L. Fracture behavior of an austenitic stainless steel with nanoscale deformation twins. Scripta Mater, 2017, 127: 173–177

Xiong L, You Z S, Lu L. Enhancing fracture toughness of na-notwinned austenitic steel by thermal annealing. Scripta Mater, 2016, 119: 55–59

Tao N R, Lu K. Dynamic plastic deformation (DPD): A novel technique for synthesizing bulk nanostructured metals. J Mater Sci Technol, 2007, 23: 771–774

You Z, Qu S, Luo S, et al. Fracture toughness evaluation of nanos-tructured metals via a contactless crack opening displacement gauge. Materialia, 2019, 7: 100430

ASTM E1820-15. Standard test method for measurement of fracture toughness. American Society of Testing and Materials, Philadelphia (PA), 2015

Xie J, Wu X, Hong Y. Shear bands at the fatigue crack tip of nano-crystalline nickel. Scripta Mater, 2007, 57: 5–8

Farkas D, Van Swygenhoven H, Derlet P M. Intergranular fracture in nanocrystalline metals. Phys Rev B, 2002, 66: 060101

Hasnaoui A, Van Swygenhoven H, Derlet P M. Dimples on nano-crystalline fracture surfaces as evidence for shear plane formation. Science, 2003, 300: 1550–1552

Li H, Ebrahimi F. Ductile-to-brittle transition in nanocrystalline metals. Adv Mater, 2005, 17: 1969–1972

Yan F K, Tao N R, Archie F, et al. Deformation mechanisms in an austenitic single-phase duplex microstructured steel with nanotwinned grains. Acta Mater, 2014, 81: 487–500

Author information

Authors and Affiliations

Corresponding author

Additional information

You Ze-Sheng was supported by the National Key R&D Program of China (Grant No. 2017YFA0204403). Lu Lei acknowledges financial support from the National Natural Science Foundation of China (Grant Nos. U1608257 and 51931010), the Key Research Program of Frontier Science and the International Partnership Program (Grant No. GJHZ2029), Chinese Academy of Sciences, and Liaoning Revitalization Talents Program (Grant No. XLYC1802026).

Rights and permissions

About this article

Cite this article

You, Z., Luo, S. & Lu, L. Size effect of deformation nanotwin bundles on their strengthening and toughening in heterogeneous nanostructured Cu. Sci. China Technol. Sci. 64, 23–31 (2021). https://doi.org/10.1007/s11431-020-1584-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1584-6