Abstract

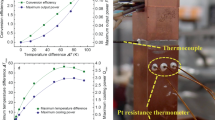

Multi-stage thermoelectric (TE) modules can withstand a large temperature difference and can be used to obtain a high conversion efficiency. In this study, two-stage PbTe/Bi2Te3 TE modules were developed with an enhanced efficiency through a comprehensive study of device structure design, module fabrication, and performance evaluation. PbTe-based AgPbmSbTem+2 (abbreviated as LAST) is a typically high ZT material, while the corresponding TE module was rarely reported so far. How to utilize LAST to fabricate high efficiency TE modules therefore remains a central problem. Finite element simulation indicates that the temperature stability of the two-stage module for LAST is better than that of two-segmented module. Compared to Cu, Ni, and Ni-Fe alloys, Co-Fe alloy is an effective metallization layer for PbTe due to its low contact resistance and thin diffusion layer. By sintering a slice of Cu on TE legs, pure tinfoil can be used as a common welding method for mid-temperature TE modules. A maximum efficiency (ηmax) of 9.5% was achieved in the range of 303 to 923 K in an optimized PbTe/Bi2Te3 based two-stage module, which was almost twice that of a commercial TE module.

Similar content being viewed by others

References

Gayner C, Kar K K. Recent advances in thermoelectric materials. Prog Mater Sci, 2016, 83: 330–382

Han C, Sun Q, Li Z, et al. Thermoelectric enhancement of different kinds of metal chalcogenides. Adv Energy Mater, 2016, 6: 1600498

Chen L G, Meng F K, Sun F R. Thermodynamic analyses and optimization for thermoelectric devices: The state of the arts. Sci China Tech Sci, 2016, 59: 442–455

Rowe D M. CRC Handbook of Thermoelectrics. New York: CRC Press, 1995. 32–39

Goldsmid H J. Introduction to Thermoelectricicty. Heidelberg: Springer, 2010

Li J F, Pan Y, Wu C F, et al. Processing of advanced thermoelectric materials. Sci China Tech Sci, 2017, 60: 1347–1364

Poudel B, Hao Q, Ma Y, et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science, 2008, 320: 634–638

Li J, Tan Q, Li J F, et al. BiSbTe-based nanocomposites with high ZT The effect of SiC nanodispersion on thermoelectric properties. Adv Funct Mater, 2013, 23: 4317–4323

Liu W S, Zhang Q, Lan Y, et al. Thermoelectric property studies on Cu-doped n-type CuxBi2Te2.7Se0.3 nanocomposites. Adv Energy Mater, 2011, 1: 577–587

Hsu K F, Loo S, Guo F, et al. Cubic AgPbmSbTe2+m: Bulk thermo-electric materials with high figure of merit. Science, 2004, 303: 818–821

Heremans J P, Jovovic V, Toberer E S, et al. Enhancement of thermoelectric efficiency in PbTe by distortion of the electronic density of states. Science, 2008, 321: 554–557

Pei Y, Shi X, LaLonde A, et al. Convergence of electronic bands for high performance bulk thermoelectrics. Nature, 2011, 473: 66–69

Zhang Q, Wang H, Zhang Q, et al. Effect of silicon and sodium on thermoelectric properties of thallium-doped lead telluride-based materials. Nano Lett, 2012, 12: 2324–2330

Zhang Q, Wang H, Liu W, et al. Enhancement of thermoelectric figure-of-merit by resonant states of aluminium doping in lead selenide. Energy Environ Sci, 2012, 5: 5246–5251

Wang H, Pei Y, LaLonde A D, et al. Weak electron-phonon coupling contributing to high thermoelectric performance in n-type PbSe. Proc Natl Acad Sci USA, 2012, 109: 9705–9709

Joshi G, Lee H, Lan Y, et al. Enhanced thermoelectric figure-of-merit in nanostructured p-type silicon germanium bulk alloys. Nano Lett, 2008, 8: 4670–4674

Wang X W, Lee H, Lan Y C, et al. Enhanced thermoelectric figure of merit in nanostructured n-type silicon germanium bulk alloy. Appl Phys Lett, 2008, 93: 193121

Liu W, Jie Q, Kim H S, et al. Current progress and future challenges in thermoelectric power generation: From materials to devices. Acta Mater, 2015, 87: 357–376

Zhao L D, Lo S H, Zhang Y, et al. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature, 2014, 508: 373–377

Zhao L D, Tan G, Hao S, et al. Ultrahigh power factor and thermoelectric performance in hole-doped single-crystal SnSe. Science, 2016, 351: 141–144

Duong A T, Nguyen V Q, Duvjir G, et al. Achieving ZT=2.2 with Bidoped n-type SnSe single crystals. Nat Commun, 2016, 7: 13713

Liu H, Yuan X, Lu P, et al. Ultrahigh thermoelectric performance by electron and phonon critical scattering in Cu2Se1−xIx. Adv Mater, 2013, 25: 6607–6612

Olvera A A, Moroz N A, Sahoo P, et al. Partial indium solubility induces chemical stability and colossal thermoelectric figure of merit in Cu2Se. Energy Environ Sci, 2017, 10: 1668–1676

Zhao L D, Berardan D, Pei Y L, et al. Bi1−xSrxCuSeO oxyselenides as promising thermoelectric materials. Appl Phys Lett, 2010, 97: 092118

Zhao L D, He J, Berardan D, et al. BiCuSeO oxyselenides: New promising thermoelectric materials. Energy Environ Sci, 2014, 7: 2900–2924

Bell L E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science, 2008, 321: 1457–1461

Yang J, Stabler F R. Automotive applications of thermoelectric materials. J Elec Materi, 2009, 38: 1245–1251

Fitriani, Ovik R, Long B D, et al. A review on nanostructures of high-temperature thermoelectric materials for waste heat recovery. Renew Sustain Energy Rev, 2016, 64: 635–659

Ikoma K, Munekiyo M, Furuya K, et al. Thermoelectric module and generator for gasoline engine vehicles. In: Seventeenth International Conference on Thermoelectrics. Nagoya: IEEE, 1998. 464–467

Amatya R, Ram R J. Solar thermoelectric generator for micropower applications. J Elec Mater, 2010, 39: 1735–1740

Hu X, Nagase K, Jood P, et al. Power generation evaluated on a bismuth telluride unicouple module. J Elec Mater, 2015, 44: 1785–1790

Chen W H, Wu P H, Wang X D, et al. Power output and efficiency of a thermoelectric generator under temperature control. Energy Convers Manage, 2016, 127: 404–415

Salvador J R, Cho J Y, Ye Z, et al. Conversion efficiency of skutterudite-based thermoelectric modules. Phys Chem Chem Phys, 2014, 16: 12510–12520

Xiao J, Yang T, Li P, et al. Thermal design and management for performance optimization of solar thermoelectric generator. Appl Energy, 2012, 93: 33–38

El-Genk M S, Saber H H, Caillat T, et al. Tests results and performance comparisons of coated and un-coated skutterudite based segmented unicouples. Energy Convers Manage, 2006, 47: 174–200

Zhang Q, Liao J, Tang Y, et al. Realizing a thermoelectric conversion efficiency of 12% in bismuth telluride/skutterudite segmented modules through full-parameter optimization and energy-loss minimized integration. Energy Environ Sci, 2017, 10: 956–963

Kraemer D, Jie Q, McEnaney K, et al. concentrating solar thermoelectric generators with a peak efficiency of 7.4%. Nat Energy, 2016, 1: 16153

Manikandan S, Kaushik S C. The influence of Thomson effect in the performance optimization of a two stage thermoelectric generator. Energy, 2016, 100: 227–237

Angeline A A, Jayakumar J, Asirvatham L G, et al. Power generation enhancement with hybrid thermoelectric generator using biomass waste heat energy. Exp Thermal Fluid Sci, 2017, 85: 1–12

Hu X, Jood P, Ohta M, et al. Power generation from nanostructured PbTe-based thermoelectrics: Comprehensive development from materials to modules. Energy Environ Sci, 2016, 9: 517–529

Li S, Pei J, Liu D, et al. Fabrication and characterization of thermoelectric power generators with segmented legs synthesized by one-step spark plasma sintering. Energy, 2016, 113: 35–43

Zhou M, Li J F, Kita T. Nanostructured AgPbmSbTem+2 system bulk materials with enhanced thermoelectric performance. J Am Chem Soc, 2008, 130: 4527–4532

Li Z Y, Li J F. Fine-grained and nanostructured AgPbmSbTem+2 alloys with high thermoelectric figure of merit at medium temperature. Adv Energy Mater, 2014, 4: 1300937

Zhao L D, Dravid V P, Kanatzidis M G. The panoscopic approach to high performance thermoelectrics. Energy Environ Sci, 2014, 7: 251–268

Kosuga A, Uno M, Kurosaki K, et al. Thermoelectric properties of Ag1-xPb18SbTe20 (x=0, 0.1, 0.3). J Alloys Compd, 2005, 387: 52–55

Kosuga A, Uno M, Kurosaki K, et al. Thermoelectric properties of stoichiometric Ag1-xPb18SbTe20 (x=0, 0.1, 0.2). J Alloys Compd, 2005, 391: 288–291

Kosuga A, Kurosaki K, Muta H, et al. Thermoelectric properties of ptype (AgSbTe2)x(Pb0.5Sn0.5Te)1-x (x=0.05, 0.09, 0.2). J Alloys Compd, 2006, 416: 218–221

Dow H S, Oh M W, Park S D, et al. Thermoelectric properties of AgPbmSbTem+2 (12≤m≤26) at elevated temperature. J Appl Phys, 2009, 105: 113703

Li H, Cai K F, Wang H F, et al. The influence of co-doping Ag and Sb on microstructure and thermoelectric properties of PbTe prepared by combining hydrothermal synthesis and melting. J Solid State Chem, 2009, 182: 869–874

Li Z Y, Li J F. Thermoelectric performance of AgPbxSbTe20 (x=17 to 23) bulk materials derived from large-particle raw materials. J Elec Mater, 2012, 41: 1365–1369

Yu Z, Li J F, Zhang B P, et al. Synthesis and thermoelectric properties of LAST system bulk materials: Substitution of sulfur for tellurium. J Elec Mater, 2012, 41: 1337–1342

Li Z Y, Zou M, Li J F. Comparison of thermoelectric performance of AgPbxSbTe20 (x=20–22.5) polycrystals fabricated by different methods. J Alloys Compd, 2013, 549: 319–323

Li Z Y, Li J F, Zhao W Y, et al. PbTe-based thermoelectric nanocomposites with reduced thermal conductivity by SiC nanodispersion. Appl Phys Lett, 2014, 104: 113905

Biswas K, He J, Blum I D, et al. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature, 2012, 489: 414–418

El-Genk M S, Saber H H, Caillat T. Efficient segmented thermoelectric unicouples for space power applications. Energy Convers Manage, 2003, 44: 1755–1772

Liu C, Pan X, Zheng X, et al. An experimental study of a novel prototype for two-stage thermoelectric generator from vehicle exhaust. J Energy Institute, 2016, 89: 271–281

Hsiao Y Y, Chang W C, Chen S L. A mathematic model of thermoelectric module with applications on waste heat recovery from automobile engine. Energy, 2010, 35: 1447–1454

Mitrani D, Tome J A, Salazar J, et al. Methodology for extracting thermoelectric module parameters. IEEE Trans Instrum Meas, 2004, 54: 1548–1552

Tsai H L, Lin J M. Model building and simulation of thermoelectric module using Matlab/Simulink. J Elec Mater, 2010, 39: 2105–2111

Jang J Y, Tsai Y C, Wu C W. A study of 3-D numerical simulation and comparison with experimental results on turbulent flow of venting flue gas using thermoelectric generator modules and plate fin heat sink. Energy, 2013, 53: 270–281

Lin T Y, Liao C N, Wu A T. Evaluation of diffusion barrier between lead-free solder systems and thermoelectric materials. J Elec Mater, 2012, 41: 153–158

Liu W, Wang H, Wang L, et al. Understanding of the contact of nanostructured thermoelectric n-type Bi2Te2.7Se0.3 legs for power generation applications. J Mater Chem A, 2013, 1: 13093

Skomedal G, Holmgren L, Middleton H, et al. Design, assembly and characterization of silicide-based thermoelectric modules. Energy Convers Manage, 2016, 110: 13–21

Kraemer D, Sui J, McEnaney K, et al. High thermoelectric conversion efficiency of MgAgSb-based material with hot-pressed contacts. Energy Environ Sci, 2015, 8: 1299–1308

D’Angelo J, Case E D, Matchanov N, et al. Electrical, thermal, and mechanical characterization of novel segmented-leg thermoelectric modules. J Elec Mater, 2011, 40: 2051–2062

Hori Y, Ito T. Fabrication of 500 degrees C class thermoelectric module and evaluation of its high temperature stability. In: 2006 25th International Conference on Thermoelectrics. Vienna: IEEE, 2006. 642–645

Guo J Q, Geng H Y, Ochi T, et al. Development of skutterudite thermoelectric materials and modules. J Elec Mater, 2012, 41: 1036–1042

Muto A, Yang J, Poudel B, et al. Skutterudite unicouple characterization for energy harvesting applications. Adv Energy Mater, 2013, 3: 245–251

Kaibe H, Aoyama I, Mukoujima M, et al. Development of thermoelectric generating stacked modules aiming for 15% of conversion efficiency. In: 24th International Conference on Thermoelectrics, 2005. Clemson, IEEE, 2005. 242–247

Anatychuk L I, Vikhor L N, Strutynska L T, et al. Segmented generator modules using Bi2Te3-based materials. J Elec Mater, 2011, 40: 957–961

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by National Key Research and Development Program of China (Grant No. 2018YFB0703600) and the National Natural Science Foundation of China (Grant No. 11474176). It is very grateful to Mr. Jin-cheng Liao at Shanghai Institute of Ceramics for his help on module performance measurement. It is very thankful to HuaBei Cooling Device Co. for providing the single Bi2Te3 TE module using commercial Bi2Te3 materials.

Rights and permissions

About this article

Cite this article

Pei, J., Li, L., Liu, D. et al. Development of integrated two-stage thermoelectric generators for large temperature difference. Sci. China Technol. Sci. 62, 1596–1604 (2019). https://doi.org/10.1007/s11431-019-9498-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-019-9498-y