Abstract

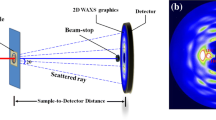

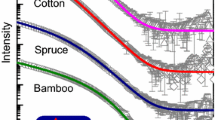

Two different chemical methods, TEMPO-oxidation and nitro-oxidation, were used to extract carboxylcellulose nanofibers (CNFs) from non-wood biomass sources (i.e., jute, soft and hard spinifex grasses). The combined TEMPO-oxidation and homogenization approach was very efficient to produce CNFs from the cellulose component of biomass; however, the nitro-oxidation method was also found to be effective to extract CNFs directly from raw biomass even without mechanical treatment. The effect of these two methods on the resulting cross-section dimensions of CNFs was investigated by solution small-angle X-ray scattering (SAXS), transmission electron microscopy (TEM) and atomic force microscopy (AFM). The UV-Vis spectroscopic data from 0.1 wt% TEMPO-oxidized nanofiber (TOCNF) and nitro-oxidized nanofiber (NOCNF) suspensions showed that TOCNF had the highest transparency (> 95%) because of better dispersion, resulted from the highest carboxylate content (1.2 mmol/g). The consistent scattering and microscopic results indicated that TOCNFs from jute and spinifex grasses possessed rectangular cross-sections, while NOCNFs exhibited near square cross-sections. This study revealed that different oxidation methods can result in different degrees of biomass exfoliation and different CNF morphology.

Similar content being viewed by others

References

Dufresne A. Nanocellulose: A new ageless bionanomaterial. Mater Today, 2013, 16: 220–227

Wang H, Li D, Zhang R. Preparation of ultralong cellulose nanofibers and optically transparent nanopapers derived from waste corrugated paper pulp. BioResources, 2013, 8: 1374–1384

Moon R J, Martini A, Nairn J, et al. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem Soc Rev, 2011, 40: 3941–3994

Sharma P R, Chattopadhyay A, Sharma S K, et al. Efficient removal of UO2 2+ from water using carboxycellulose nanofibers prepared by the nitro-oxidation method. Ind Eng Chem Res, 2017, 56: 13885–13893

Siqueira G, Bras J, Dufresne A. Cellulosic bionanocomposites: A review of preparation, properties and applications. Polymers, 2010, 2: 728–765

Hubbe M A, Rojas O J, Lucia L A, et al. Cellulosic nanocomposites: A review. BioResources, 2008, 3: 929–980

Siró I, Plackett D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose, 2010, 17: 459–494

Lalia B S, Samad Y A, Hashaikeh R. Nanocrystalline-cellulose-re-inforced poly(vinylidenefluoride-co-hexafluoropropylene) nano-composite films as a separator for lithium ion batteries. J Appl Polym Sci, 2012, 126: E442–E448

Emami Z, Meng Q, Pircheraghi G, et al. Use of surfactants in cellulose nanowhisker/epoxy nanocomposites: Effect on filler dispersion and system properties. Cellulose, 2015, 22: 3161–3176

Razaq A, Nyström G, Strømme M, et al. High-capacity conductive nanocellulose paper sheets for electrochemically controlled extraction of DNA oligomers. PLoS ONE, 2011, 6: e29243

Ma H, Burger C, Hsiao B S, et al. Nanofibrous microfiltration membrane based on cellulose nanowhiskers. Biomacromolecules, 2012, 13: 180–186

Wang R, Guan S, Sato A, et al. Nanofibrous microfiltration membranes capable of removing bacteria, viruses and heavy metal ions. J Membrane Sci, 2013, 446: 376–382

Ferraz N, Leschinskaya A, Toomadj F, et al. Membrane characterization and solute diffusion in porous composite nanocellulose membranes for hemodialysis. Cellulose, 2013, 20: 2959–2970

Quinlan P J, Tanvir A, Tam K C. Application of the central composite design to study the flocculation of an anionic azo dye using quaternized cellulose nanofibrils. Carbohydr Polym, 2015, 133: 80–89

Yu H Y, Zhang D Z, Lu F F, et al. New approach for single-step extraction of carboxylated cellulose nanocrystals for their use as adsorbents and flocculants. ACS Sust Chem Eng, 2016, 4: 2632–2643

Carpenter A W, de Lannoy C F, Wiesner M R. Cellulose nanomaterials in water treatment technologies. Environ Sci Technol, 2015, 49: 5277–5287

Quellmalz A, Mihranyan A. Citric acid cross-linked nanocellulose-based paper for size-exclusion nanofiltration. ACS Biomater Sci Eng, 2015, 1: 271–276

Tang Z, Qiu C, McCutcheon J R, et al. Design and fabrication of electrospun polyethersulfone nanofibrous scaffold for high-flux nanofiltration membranes. J Polym Sci B Polym Phys, 2009, 47: 2288–2300

Mautner A, Lee K Y, Lahtinen P, et al. Nanopapers for organic solvent nanofiltration. Chem Commun, 2014, 50: 5778–5781

Sun D, Yang J, Wang X. Bacterial cellulose/TiO2 hybrid nanofibers prepared by the surface hydrolysis method with molecular precision. Nanoscale, 2010, 2: 287–292

Huang W, Wang Y, Chen C, et al. Fabrication offlexible self-standing all-cellulose nanofibrous composite membranes for virus removal. Carbohydr Polym, 2016, 143: 9–17

Sato A, Wang R, Ma H, et al. Novel nanofibrous scaffolds for water filtration with bacteria and virus removal capability. J Electron Microsc, 2011, 60: 201–209

Sharma P R, Chattopadhyay A, Sharma S K, et al. Nanocellulose from spinifex as an effective adsorbent to remove cadmium(II) from water. ACS Sustain Chem Eng, 2018, 6: 3279–3290

Wu C, Wang Y, Gao B, et al. Coagulation performance and floc characteristics of aluminum sulfate using sodium alginate as coagulant aid for synthetic dying wastewater treatment. Separation Purification Tech, 2012, 95: 180–187

Suopajärvi T, Liimatainen H, Hormi O, et al. Coagulation-flocculation treatment of municipal wastewater based on anionized nanocelluloses. Chem Eng J, 2013, 231: 59–67

Feng X, Huang R Y M. Liquid separation by membrane pervaporation: A review. Indust Eng Chem Res, 1997, 36: 1048–1066

Werber J R, Osuji C O, Elimelech M. Materials for next-generation desalination and water purification membranes. Nat Rev Mater, 2016, 1: 16018

He X, Male K B, Nesterenko P N, et al. Adsorption and desorption of methylene blue on porous carbon monoliths and nanocrystalline cellulose. ACS Appl Mater Interfaces, 2013, 5: 8796–8804

Alsbaiee A, Smith B J, Xiao L, et al. Rapid removal of organic mi-cropollutants from water by a porous β-cyclodextrin polymer. Nature, 2016, 529: 190–194

Korotta-Gamage S M, Sathasivan A. A review: Potential and challenges of biologically activated carbon to remove natural organic matter in drinking water purification process. Chemosphere, 2017, 167: 120–138

Mahmoudi K, Hamdi N, Srasra E. Study of adsorption of methylene blue onto activated carbon from lignite. Surf Engin Appl Electrochem, 2015, 51: 427–433

Wang B, Torres-Rendon J G, Yu J, et al. Aligned bioinspired cellulose nanocrystal-based nanocomposites with synergetic mechanical properties and improved hygromechanical performance. ACS Appl Mater Interfaces, 2015, 7: 4595–4607

Kardam A, Raj K R, Srivastava S, et al. Nanocellulose fibers for biosorption of cadmium, nickel, and lead ions from aqueous solution. Clean Techn Environ Policy, 2013, 16: 385–393

Zhang Z, Sèbe G, Rentsch D, et al. Ultralightweight and flexible silylated nanocellulose sponges for the selective removal of oil from water. Chem Mater, 2014, 26: 2659–2668

Metreveli G, Wågberg L, Emmoth E, et al. A size-exclusion nano-cellulose filter paper for virus removal. Adv Healthcare Mater, 2014, 3: 1546–1550

Xie K, Zhao W, He X. Adsorption properties of nano-cellulose hybrid containing polyhedral oligomeric silsesquioxane and removal of reactive dyes from aqueous solution. Carbohydr Polym, 2011, 83: 1516–1520

Anirudhan T S, Deepa J R, Christa J. Nanocellulose/nanobentonite composite anchored with multi-carboxyl functional groups as an adsorbent for the effective removal of cobalt(II) from nuclear industry wastewater samples. J Colloid Interface Sci, 2016, 467: 307–320

Wen X, Zheng Y, Wu J, et al. Immobilization of collagen peptide on dialdehyde bacterial cellulose nanofibers via covalent bonds for tissue engineering and regeneration. Int J Nanomed, 2015, 4623–4637

Zhu H, Luo W, Ciesielski P N, et al. Wood-derived materials for green electronics, biological devices, and energy applications. Chem Rev, 2016, 116: 9305–9374

Sharma R, Alam F, Sharma A K, et al. ZnO anchored graphene hydrophobic nanocomposite-based bulk heterojunction solar cells showing enhanced short-circuit current. J Mater Chem C, 2014, 2: 8142–8151

Fang Z, Zhu H, Yuan Y, et al. Novel nanostructured paper with ultrahigh transparency and ultrahigh haze for solar cells. Nano Lett, 2014, 14: 765–773

Fukuzumi H, Fujisawa S, Saito T, et al. Selective permeation of hydrogen gas using cellulose nanofibril film. Biomacromolecules, 2013, 14: 1705–1709

Shah K J, Imae T. Selective gas capture ability of gas-adsorbent-incorporated cellulose nanofiber films. Biomacromolecules, 2016, 17: 1653–1661

Ghosh A K, Bandyopadhyay P. A simple strategy for charge selective biopolymer sensing. Chem Commun, 2011, 47: 8937–8939

Sharma P R, Varma A J. Functional nanoparticles obtained from cellulose: Engineering the shape and size of 6-carboxycellulose. Chem Commun, 2013, 49: 8818–8820

Reid M S, Villalobos M, Cranston E D. Benchmarking cellulose na-nocrystals: From the laboratory to industrial production. Langmuir, 2017, 33: 1583–1598

Xu X, Liu F, Jiang L, et al. Cellulose nanocrystals vs. cellulose na-nofibrils: A comparative study on their microstructures and effects as polymer reinforcing agents. ACS Appl Mater Interfaces, 2013, 5: 2999–3009

Saito T, Kimura S, Nishiyama Y, et al. Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules, 2007, 8: 2485–2491

Isogai A, Saito T, Fukuzumi H. TEMPO-oxidized cellulose nanofibers. Nanoscale, 2011, 3: 71–85

Han J, Zhou C, French A D, et al. Characterization of cellulose II nanoparticles regenerated from 1-butyl-3-methylimidazolium chloride. Carbohydr Polym, 2013, 94: 773–781

Tzhayik O, Pulidindi I N, Gedanken A. Forming nanospherical cellulose containers. Ind Eng Chem Res, 2014, 53: 13871–13880

Sharma P R, Varma A J. Functionalized celluloses and their nano-particles: Morphology, thermal properties, and solubility studies. Carbohydr Polym, 2014, 104: 135–142

Sharma P R, Kamble S, Sarkar D, et al. Shape and size engineered cellulosic nanomaterials as broad spectrum anti-microbial compounds. Int J Biol Macromol, 2016, 87: 460–465

Sharma P R, Rajamohanan P R, Varma A J. Supramolecular transitions in native cellulose-I during progressive oxidation reaction leading to quasi-spherical nanoparticles of 6-carboxycellulose. Carbohydr Polym, 2014, 113: 615–623

Sharma P R, Joshi R, Sharma S K, et al. A simple approach to prepare carboxycellulose nanofibers from untreated biomass. Biomacromolecules, 2017, 18: 2333–2342

Nechyporchuk O, Belgacem M N, Pignon F. Current progress in rheology of cellulose nanofibril suspensions. Biomacromolecules, 2016, 17: 2311–2320

Luo G, Xie L, Zou Z, et al. Evaluation of pretreatment methods on mixed inoculum for both batch and continuous thermophilic biohydrogen production from cassava stillage. Bioresour Tech, 2010, 101: 959–964

Amiralian N, Annamalai P K, Memmott P, et al. Easily deconstructed, high aspect ratio cellulose nanofibres from Triodia pungens; an abundant grass of Australia’s arid zone. RSC Adv, 2015, 5: 32124–32132

Su Y, Burger C, Ma H, et al. Morphological and property investigations of carboxylated cellulose nanofibers extracted from different biological species. Cellulose, 2015, 22: 3127–3135

Saito T, Nishiyama Y, Putaux J L, et al. Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromol, 2006, 7: 1687–1691

Puangsin B, Yang Q, Saito T, et al. Comparative characterization of TEMPO-oxidized cellulose nanofibril films prepared from non-wood resources. Int J Biol Macromol, 2013, 59: 208–213

Meng Q, Li H, Fu S, et al. The non-trivial role ofnative xylans on the preparation of TEMPO-oxidized cellulose nanofibrils. React Funct Poly, 2014, 85: 142–150

Su Y, Burger C, Ma H, et al. Exploring the nature of cellulose microfibrils. Biomacromolecules, 2015, 16: 1201–1209

Amiralian N, Annamalai P K, Memmott P, et al. Isolation of cellulose nanofibrils from Triodia pungens via different mechanical methods. Cellulose, 2015, 22: 2483–2498

Jacobsen S E, Wyman C E. Cellulose and hemicellulose hydrolysis models for application to current and novel pretreatment processes. Appl Biochem Biotechnol, 2000, 84–86: 81–96

Ma H, Burger C, Hsiao B S, et al. Ultra-fine cellulose nanofibers: New nano-scale materials for water purification. J Mater Chem, 2011, 21: 7507–7510

Okita Y, Saito T, Isogai A. Entire surface oxidation of various cellulose microfibrils by TEMPO-mediated oxidation. Biomacromolecules, 2010, 11: 1696–1700

Mao Y, Liu K, Zhan C, et al. Characterization of nanocellulose using small-angle neutron, X-ray, and dynamic light scattering techniques. J Phys Chem B, 2017, 121: 1340–1351

Sugiyama J, Vuong R, Chanzy H. Electron diffraction study on the two crystalline phases occurring in native cellulose from an algal cell wall. Macromolecules, 1991, 24: 4168–4175

Fujisaki Y, Koga H, Nakajima Y, et al. Transparent nanopaper-based flexible organic thin-film transistor array. Adv Funct Mater, 2014, 24: 1657–1663

Cosgrove D J. Growth of the plant cell wall. Nat Rev Mol Cell Bio, 2005, 6: 850–861

Kumar R, Hu F, Hubbell C A, et al. Comparison of laboratory delignification methods, their selectivity, and impacts on physiochemical characteristics of cellulosic biomass. Bioresour Tech, 2013, 130: 372–381

Okita Y, Saito T, Isogai A. TEMPO-mediated oxidation of softwood thermomechanical pulp. Holzforschung, 2009, 63: 529–535

Dimmel D R, Karim M R, Savidakis M C, etal. Pulping catalysts from lignin (5). Nitrogen dioxide oxidation of lignin models to benzoquinones. J Wood Chem Technol, 1996, 16: 169–189

Sharma P R, Zheng B, Sharma S K, et al. High aspect ratio carboxycellulose nanofibers prepared by nitro-oxidation method and their nanopaper properties. ACS Appl Nano Mater, 2018, 1: 3969–3980

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhan, C., Sharma, P.R., Geng, L. et al. Structural characterization of carboxyl cellulose nanofibers extracted from underutilized sources. Sci. China Technol. Sci. 62, 971–981 (2019). https://doi.org/10.1007/s11431-018-9441-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-018-9441-1