Abstract

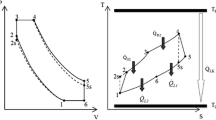

This study reports a new model of an air standard Dual-Miller cycle (DMC) with two polytropic processes and heat transfer loss. The two reversible adiabatic processes which could not be realized in practice are replaced with two polytropic processes in order to more accurately reflect the practical working performance. The heat transfer loss is taken into account. The expressions of power output, thermal efficiency, entropy generation rate (EGR) and ecological function are addressed using finite-time thermodynamic theory. Through numerical calculations, the influences of compression ratio, cut-off ratio and polytropic exponent on the performance are thermodynamically analyzed. The model can be simplified to other cycle models under specific conditions, which means the results have an certain universality and may be helpful in the design of practical heat engines. It is shown that the entropy generation minimization does not always lead to the best system performance.

Similar content being viewed by others

References

Andresen B. Finite-Time Thermodynamics. Physics Laboratory II. University of Copenhagen, 1983

Andresen B, Berry R S, Ondrechen M J, et al. Thermodynamics for processes in finite time. Acc Chem Res, 1984, 17: 266–271

Bejan A. Entropy generation minimization: The new thermodynamics of finite-size devices and finite-time processes. J Appl Phys, 1996, 79: 1191–1218

Berry R S, Kazakov V A, Sieniutycz S, et al. Thermodynamic Optimization of Finite Time Processes. Chichester: Wiley, 1999

Chen L G, Wu C, Sun F R. Finite time thermodynamic optimization or entropy generation minimization of energy systems. J Non-Equilib Thermodyn, 1999, 24: 327–359

Salamon P, Nulton J D, Siragusa G, et al. Principles of control thermodynamics. Energy, 2001, 26: 307–319

Chen L G, Sun F R. Advances in Finite Time Thermodynamics: Analysis and optimization. New York: Nova Science Publishers, 2004

Chen L G. Finite Time Thermodynamic Analysis of Irreversible Process and Cycles (in Chinese). Beijing: Higher Education Press, 2005

Sieniutycz S, Jezowski J. Energy Optimization in Process Systems. Oxford, UK: Elsevier, 2009

Andresen B. Current trends in finite-time thermodynamics. Angew Chem Int Ed, 2011, 50: 2690–2704

Wu F, Chen L G, Sun F R, et al. Finite Time Thermodynamic Optimization of Stirling Machine (in Chinese). Beijing: Chemical Industry Press, 2008

Sieniutycz S, Jezowski J. Energy Optimization in Process Systems and Fuel Cells. Oxford, UK: Elsevier, 2013

Medina A, Curto-Risso P L, Calvo-Hernández A, et al. Quasi-Dimensional Simulation of Spark Ignition Engines. From Thermodynamic Optimization to Cyclic Variability. London: Springer, 2014

Ding Z M, Chen L G, Wang W H, et al. Advances in finite time thermodynamic performance optimization of three kinds of micro energy conversion systems (in Chinese). Sci Sin Tech, 2015, 45: 889–918

Hoffmann K H, Andresen B, Salamon P. Finite-time thermodynamics tools to analyze dissipative processes. In: Dinner A R, Eds. Proceedings of the 240 Conference: Science’s Great Challences, Advances in Chemical Physics. Volume 157. New Jersey: Wiley, 2015. 57–67

Ahmadi M H, Ahmadi M A, Sadatsakkak S A. Thermodynamic analysis and performance optimization of irreversible Carnot refrigerator by using multi-objective evolutionary algorithms (MOEAs). Renew Sust Energ Rev, 2015, 51: 1055–1070

Chen L G, Meng F K, Sun F R. Thermodynamic analyses and optimization for thermoelectric devices: The state of the arts. Sci China Tech Sci, 2016, 59: 442–455

Chen L, Feng H, Xie Z. Generalized thermodynamic optimization for iron and steel production processes: Theoretical exploration and application cases. Entropy, 2016, 18: 353

Sieniutycz S. Thermodynamic Approaches in Engineering Systems. Oxford: Elsevier, 2016

Chen L G, Xia S J. Generalized Thermodynamics Dynamic Optimization of Irreversible Processes (in Chinese). Beijing: Science Press, 2016

Chen L G, Xia S J. Generalized Thermodynamics Dynamic Optimization of Irreversible Cycles (in Chinese). Beijing: Science Press, 2016

Bi Y H, Chen L G. Finite time thermodynamic optimization of air heat pump performance (in Chinese). Beijing: Science Press, 2017

Ahmadi M H, Ahmadi M A, Pourfayaz F. Thermal models for analysis of performance of Stirling engine: A review. Renew Sust Energ Rev, 2017, 68: 168–184

Ge Y, Chen L, Sun F. Progress in finite time thermodynamic studies for internal combustion engine cycles. Entropy, 2016, 18: 139

Chen L, Zhang W, Sun F. Power, efficiency, entropy-generation rate and ecological optimization for a class of generalized irreversible universal heat-engine cycles. Appl Energy, 2007, 84: 512–525

Zhou B, Cheng X T, Liang X G. Power output analyses and optimizations of the Stirling cycle. Sci China Tech Sci, 2013, 56: 228–236

Ge Y, Chen L, Sun F. Optimal path of piston motion of irreversible Otto cycle for minimum entropy generation with radiative heat transfer law. J Energy Inst, 2012, 85: 140–149

Wang C, Chen L, Xia S, et al. Optimal concentration configuration of consecutive chemical reaction A ⇔ B ⇔ C for minimum entropy generation. J Non-Equilib ThermoDyn, 2016, 41: 313–326

Wu Y Q. Analyses of thermodynamic performance for the endoreversible Otto cycle with the concepts of entropy generation and entransy. Sci China Tech Sci, 2017, 60: 692–700

Angulo-Brown F. An ecological optimization criterion for finite-time heat engines. J Appl Phys, 1991, 69: 7465–7469

Yan Z J. Comment on “ecological optimization criterion for finitetime heat engines”. J Appl Phys, 1993, 73: 3583

Angulo-Brown F, Fernández-Betanzos J, Diaz-Pico C A. Compression ratio of an optimized air standard Otto-cycle model. Eur J Phys, 1994, 15: 38–42

Chen L G, Sun F R, Chen W Z. The ecological quality factor for thermodynamic cycles (in Chinese). J Eng Therm Energy Power, 1994, 9: 374–376

Long R, Li B, Liu Z, et al. Ecological analysis of a thermally regenerative electrochemical cycle. Energy, 2016, 107: 95–102

Üst Y, Sahin B, Kodal A. Ecological coefficient of performance (ECOP) optimization for generalized irreversible Carnot heat engines. J Energy Inst, 2005, 78: 145–151

Ust Y, Sahin B, Sogut O S. Performance analysis and optimization of an irreversible dual-cycle based on an ecological coefficient of performance criterion. Appl Energy, 2005, 82: 23–39

Ust Y, Sahin B, Kodal A. Performance analysis of an irreversible Brayton heat engine based on ecological coefficient of performance criterion. Int J Thermal Sci, 2006, 45: 94–101

Ust Y. Performance analysis and optimization of irreversible air refrigeration cycles based on ecological coefficient of performance criterion. Appl Thermal Eng, 2009, 29: 47–55

Gonca G, Sahin B. Performance optimization of an air-standard irreversible dual-atkinson cycle engine based on the ecological coefficient of performance criterion. Sci World J, 2014, 2014: 1–10

Ust Y, Sahin B, Cakir M. Ecological coefficient of performance analysis and optimisation of gas turbines by using exergy analysis approach. Int J Exergy, 2016, 21: 39–69

Salamon P, Hoffmann K H, Schubert S, et al. What conditions make minimum entropy production equivalent to maximum power production? J Non-Equilib Thermodyn, 2001, 26: 73–83

Blank D A, Wu C. The effects of combustion on a power-optimized endoreversible Dual cycle. Energy Conv Manag, 1994, 14: 98–103

Chen L, Sun F, Wu C. Optimal performance of an irreversible dualcycle. Appl Energy, 2004, 79: 3–14

Ust Y, Sahin B, Kayadelen H K, et al. Heat transfer effects on the performance of an air-standard irreversible dual cycle. Int J Vehicle Des, 2013, 63: 102

Ghatak A, Chakraborty S. Effect of external irreversibilities and variable thermal properties of working fluid on thermal performance of a Dual internal combustion engine cycle. Strojnicky Casopsis (J Mech Energy), 2007, 58: 1–12

Wang W, Chen L, Sun F, et al. The effect of friction on the performance of an air standard dual cycle. Exergy An Int J, 2002, 2: 340–344

Ge Y, Chen L, Sun F. Finite-time thermodynamic modeling and analysis for an irreversible Dual cycle. Math Comp Model, 2009, 50: 101–108

Al-Sarkhi A, Akash B A, Jaber J O, et al. Efficiency of miller engine at maximum power density. Int Commun Heat Mass Transfer, 2002, 29: 1159–1167

Chen L G, Ge Y L, Sun F R, et al. The performance of a Miller cycle with heat transfer, friction and variable specific heats of working fluid. Termotehnica, 2010, 14: 24–32

Chen L, Ge Y, Sun F, et al. Finite-time thermodynamic modelling and analysis for an irreversible Miller cycle. Int J Ambient Energy, 2011, 32: 87–94

Lin J, Xu Z, Chang S, et al. Finite-time thermodynamic modeling and analysis of an irreversible Miller cycle working on a four-stroke engine. Int Commun Heat Mass Transfer, 2014, 54: 54–59

Gonca G, Sahin B, Ust Y, et al. Comparison of steam injected diesel engine and Miller cycled diesel engine by using two zone combustion model. J Energy Inst, 2015, 88: 43–52

Gonca G, Sahin B, Parlak A, et al. Theoretical and experimental investigation of the Miller cycle diesel engine in terms of performance and emission parameters. Appl Energy, 2015, 138: 11–20

Ebrahimi R. Second law analysis on an air-standard miller engine. Acta Phys Pol A, 2016, 129: 1079–1082

Mousapour A, Hajipour A, Rashidi M M, et al. Performance evaluation of an irreversible Miller cycle comparing FTT (finite-time thermodynamics) analysis and ANN (artificial neural network) prediction. Energy, 2016, 94: 100–109

Zhao J. Research and application of over-expansion cycle (Atkinson and Miller) engines—A review. Appl Energ, 2017, 185: 300–319

Gonca G, Sahin B, Ust Y. Performance maps for an air-standard irreversible Dual-Miller cycle (DMC) with late inlet valve closing (LIVC) version. Energy, 2013, 54: 285–290

Gonca G, Sahin B, Ust Y. Investigation of heat transfer influences on performance of air-standard irreversible Dual-Miller cycle. J Thermophys Heat Transfer, 2015, 29: 678–683

Gonca G. Comparative performance analyses of irreversible OMCE (Otto Miller cycle engine)-DiMCE (Diesel miller cycle engine)-DMCE (Dual Miller cycle engine). Energy, 2016, 109: 152–159

Ust Y, Arslan F, Ozsari I, et al. Thermodynamic performance analysis and optimization of DMC (Dual Miller Cycle) cogeneration system by considering exergetic performance coefficient and total exergy output criteria. Energy, 2015, 90: 552–559

Gonca G. Thermo-ecological analysis of irreversible Dual-Miller Cycle (DMC) engine based on the ecological coefficient of performance (ECOP) criterion. Iran J Sci Tech Trans Mech Eng, 2016: 1–12

Gonca G, Sahin B. Thermo-ecological performance analyses and optimizations of irreversible gas cycle engines. Appl Thermal Eng, 2016, 105: 566–576

Wu Z X, Chen L G, Ge Y L, et al. Ecological objective function optimization of an irreversible Dual-Miller cycle with linear variable specific heat ratio of the working fluid (in Chinese). Energy Conser, 2016, 6: 20–27

Wu Z X, Chen L G, Ge Y L, et al. Power, efficiency, ecological function and ecological coefficient of performance of an irreversible Dual-Miller cycle (DMC) with nonlinear variable specific heat ratio of working fluid. Euro Phys J Plus, 2017, 132: 209

Huleihil M, Mazor G. Irreversible performance characteristics of air standard Otto cycles with polytropic processes. Appl Mech Eng, 2012, 1: 1000111

Gong S W, Chen L G, Sun F R. Performance analysis and optimization of endoreversible Lenoir cycle with polytropic process (in Chinese). Energy Conser, 2013, 32: 22–26

Xiong B, Chen L G, Ge Y L, et al. Finite-time thermodynamic analysis of an endoreversible Otto cycle with polytropic process (in Chinese). Power Energy, 2014, 35: 166–171

Zhang K, Chen L G, Qin X Y, et al. Finite time thermodynamic analysis of irreversible universal reciprocating cycle with polytropic process (in Chinese). Energy Conser, 2015, 34: 15–21

Klein S A. An explanation for observed compression ratios in internal combustion engines. J Eng Gas Turbines Power, 1991, 113: 511–513

Ge Y, Chen L, Sun F. Ecological optimization of an irreversible otto cycle. Arab J Sci Eng, 2013, 38: 373–381

Ge Y, Chen L, Sun F, et al. Effects of heat transfer and variable specific heats of working fluid on performance of a Miller cycle. Int J Ambient Energy, 2005, 26: 203–214

Chen L, Zheng T, Sun F, et al. The power and efficiency characteristics for an irreversible Otto cycle. Int J Ambient Energy, 2003, 24: 195–200

Ebrahimi R. Performance of an irreversible Diesel cycle under variable stroke length and compression ratio. J Am Sci, 2009, 5: 58–64

Bejan A. Models of power plants that generate minimum entropy while operating at maximum power. Am J Phys, 1996, 64: 1054–1059

Guo Z Y, Zhu H Y, Liang X G. Entransy—A physical quantity describing heat transfer ability. Int J Heat Mass Transfer, 2007, 50: 2545–2556

Chen Q, Liang X G, Guo Z Y. Entransy theory for the optimization of heat transfer—A review and update. Int J Heat Mass Transfer, 2013, 63: 65–81

Cheng X T, Liang X G. Entransy, entransy dissipation and entransy loss for analyses of heat transfer and heat-work conversion processes. J Therm Sci Technol, 2013, 8: 337–352

Cheng X T, Liang X G. Entransy: Its physical basis, applications and limitations. Chin Sci Bull, 2014, 59: 5309–5323

Chen L G. Progress in optimization of mass transfer processes based on mass entransy dissipation extremum principle. Sci China Tech Sci, 2014, 57: 2305–2327

Cheng X T, Liang X G. Entransy analyses of heat-work conversion systems with inner irreversible thermodynamic cycles. Chin Phys B, 2015, 24: 120503

Chen L G, Feng H J. Multi-objective Constructal Optimization for Flow and Heat and Mass Transfer Processes. Beijing: Science Press, 2016

Zhang T, Liu X H, Tang H D, et al. Progress of entransy analysis on the air-conditioning system in buildings. Sci China Tech Sci, 2016, 59: 1463–1474

Kim K H, Kim K. Comparative analyses of energy-exergy-entransy for the optimization of heat-work conversion in power generation systems. Int J Heat Mass Transfer, 2015, 84: 80–90

Cheng X T, Zhao J M, Liang X G. Discussion on the extensions of the entransy theory. Sci China Tech Sci, 2017, 60: 363–373

Cheng X T, Liang X G. Entransy analyses of the thermodynamic cycle in a turbojet engine. Sci China Tech Sci, 2017, 60: 1160–1167

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

You, J., Chen, L., Wu, Z. et al. Thermodynamic performance of Dual-Miller cycle (DMC) with polytropic processes based on power output, thermal efficiency and ecological function. Sci. China Technol. Sci. 61, 453–463 (2018). https://doi.org/10.1007/s11431-017-9108-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-017-9108-2