Abstract

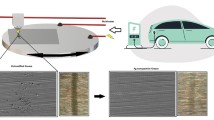

Experiments were performed on 20 different types of materials to analyze the impact contact wear and to establish the wear mechanism map. The wear mechanism has been categorized into three prominent regions (delamination wear, quasi-nano wear and lamination-like wear) and is governed by two hardness thresholds (Hdq and Hql). When the material hardness Hcp<Hdq, the delamination wear is the dominant wear mechanism; when Hcp>Hql, the mechanism is lamination-like wear; however, when Hcp is between Hdq and Hql, the mechanism is determined to be quasi-nano wear. Hdq is determined to be the threshold hardness between delamination wear and quasi-nano wear that reflects the cracks being produced in the subsurface layer, whereas, Hql is termed threshold hardness between quasi-nano wear and lamination-like wear with formation of nanostructure within the surface layer.

Similar content being viewed by others

References

Wellinger K, Breckel H. Kenngrössen und verschleiss beim stoss metallischer werkstoffe. Wear, 1969, 13: 257–281

Bayer R G, Engel P A, Sirico J L. Impact wear testing machine. Wear, 1972, 19: 343–354

Rice S L, Wayne S F. Wear of two titanium alloys under repetitive compound impact. Wear, 1980, 61: 69–76

Iturbe E B, Greenfield I G, Chou T W. The wear mechanism obtained in copper by repetitive impacts. Wear, 1981, 74: 123–129

Nowotny H, Rice S L, Wayne S F. Characteristics of wear debris in impact sliding. Wear, 1981, 68: 159–167

Chen Y M, Zhu J H, Xie F, et al. Surface failure under repeated impact contact loading. In: Maekawa I, ed. Proceedings of the International Symposium on Impact Engineering. Sendai: ISIE, 1992. II: 646–651

Chen Y M, Zhu J H, Li P L, et al. Impact wear resistance of exhaust valve seats of EQ6100 gasoline engine at high temperatures (in Chinese). Chin Intern Combust Engine Eng, 1992, 13: 67–73

Blau P J. Fifty years of research on the wear of metals. Tribology Int, 1997, 30: 321–331

Rice S L, Nowotny H, Wayne S F. Characteristics of metallic subsurface zones in sliding and impact wear. Wear, 1981, 74: 131–142

Suh N P. The delamination theory of wear. Wear, 1973, 25: 111–124

Jahanmir S, Suh N P. Mechanics of subsurface void nucleation in delamination wear. Wear, 1977, 44: 17–38

Fleming J R, Suh N P. Mechanics of crack propagation in delamination wear. Wear, 1977, 44: 39–56

Zhu J H, Ren X H, Zhang J J, et al. Quasi-nano wear mechanism under repeated impact contact loading. Sci China Technol Sci, 2010, 53: 1583–1589

Ren X H, Zhu J H. The effect of substitutional alloying elements on the impact wear rate of medium carbon steels related to delamination and quasi-nanometer wear mechanisms. Mater Sci Eng-A, 2011, 528: 7020–7023

Levy A V. The platelet mechanism of erosion of ductile metals. Wear, 1986, 108: 1–21

Kjer T. A lamination wear mechanism based on plastic waves. In: Ludema K C, ed. Proceedings of the International Conference on Wear of Materials. Huston: ASME, 1987. 191–198

Zhang J J, Zhu J H. Surface structure evolution and abnormal wear behavior of the TiNiNb alloy under impact load. Metall Mat Trans A, 2009, 40: 1126–1130

Zhang J J. Microstructure evolution and wear mechanism of materials under repeated impact contact load (in Chinese). Dissertation of Doctoral Degree. Xi’an: Xi’an Jiaotong University, 2006

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, X., Zhu, J. Wear mechanisms and hardness thresholds under repeated impact contact loading. Sci. China Technol. Sci. 61, 124–128 (2018). https://doi.org/10.1007/s11431-016-9145-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-016-9145-1