Abstract

A reduced combustion kinetic model for the methanol-gasoline blended fuels for SI engines was developed. Sensitivity analysis and rate constant variation methods were used to optimize the kinetic model. Flame propagation, shock-tube and jet-stirred reactor systems were modeled in CHEMKIN. The laminar flame speed, ignition delay time and change in concentrations of species were simulated using the reduced kinetic model. The simulation results of reduced chemical mechanism agreed well with the relevant experimental data published in the literature. The experimental investigations on engine bench were also carried out. The in-cylinder pressure and exhaust emissions were obtained by using a combustion analyzer and an FTIR (Fourier transform infrared spectroscopy) spectrometer. Meanwhile, an engine in-cylinder CFD model was established in AVL FIRE and was coupled with the proposed reduced chemical mechanism to simulate the combustion process of methanol-gasoline blends. The simulated combustion process showed good agreement with the engine experimental results and the predicted emissions were found to be in accordance with the FTIR results.

Similar content being viewed by others

References

Liao, S Y, Jiang D M, Cheng Q, et al. Effect of methanol addition into gasoline on the combustion characteristics at relatively low temperatures. Energ Fuel, 2005, 20: 84–90

Wang Z, Xu Y Q, Wang J X. Suppression of super-knock in TC-GDI engine using two-stage injection in intake stroke (TSII). Sci China Tech Sci, 2014, 57: 80–85

Zhang L P, Liu Z C, Tian J, et al. Investigation of the combustion deterioration of an automotive diesel engine under transient operation. Sci China Tech Sci, 2014, 57: 480–488

Liu S, Clemente E R C, Hu T, et al. Study of spark ignition engine fueled with methanol/gasoline fuel blends. Appl Therm Eng, 2007, 27: 1904–1910

Qin W J, Xie M Z, Jia M, et al. Large eddy simulation and proper orthogonal decomposition analysis of turbulent flows in a direct injection spark ignition engine: Cyclic variation and effect of valve lift. Sci China Tech Sci, 2014, 57: 489–504

Bowman C T. A shock-tube investigation of the high-temperature oxidation of methanol. Combust Flame, 1975, 75: 343–354

Aronowitz D, Santoro R J, Er F L, et al. Kinetics of the oxidation of methanol: Experimental results semi-global modeling and mechanistic concepts. Symp Combust, 1979, 17: 633–644

Westbrook C K, Dryer F L. A comprehensive mechanism for methanol oxidation. Combust Sci Technol, 1979, 20: 125–140

Tsang W. Chemical Kinetic Data Base for Combustion Chemistry. Part 2. Methanol. J Phys Chem Ref Data, 1987, 16: 471–508

Norton T S, Dryer F L. Some new observations on methanol oxidation chemistry. Combust Sci Technol, 1989, 63: 107–129

Egolfopoulos F N, Du D X, Law C K. A comprehensive study of methanol kinetics in freely-propagating and burner-stabilized flames, flow and static reactors, and shock tubes. Combust Sci Technol, 1992, 83: 33–75

Grotheer H H, Kelm S, Driver H S T, et al. Elementary reactions in the methanol oxidation system. Part I: Establishment of the mechanism and modelling of laminar burning velocities. Phys Chem Chem Phys, 1992, 96: 1360

Held T J, Dryer F L. An experimental and computational study of methanol oxidation in the intermediate-and high-temperature regimes. Symp Combust, 1994, 25: 901–908

Li J, Zhao Z, Kazakov A, et al. A comprehensive kinetic mechanism for CO, CH2O, and CH3OH combustion. Int J Chem Kinet, 2007, 39: 109–136

Curran H J, Gaffuri P, Pitz W J, et al. A comprehensive modeling study of iso-octane oxidation. Combust Flame, 2002, 129: 253–280.

Curran H J, Gaffuri P, Pitz W J, et al. A comprehensive modeling study of n-heptane oxidation. Combust Flame, 1998, 114: 149–177

Come G M, Warth V, Glaude P A, et al. Computer-aided design of gas-phase oxidation mechanisms—application to the modeling of n -heptane and iso-octane oxidation. Symp Combust, 1996, 26: 755–762

Dagaut P, Reuillon M, Cathonnet M. High pressure oxidation of liquid fuels from low to high temperature. 1. n-Heptane and iso-Octane. Combust Sci Technol, 1994, 95: 233–260

Emdee J L, Brezinsky K, Glassman I. A kinetic model for the oxidation of toluene near 1200 K. J Cheminformatics, 2002, 23

Dagaut P, Pengloan G, Ristori A. Oxidation, ignition and combustion of toluene: Experimental and detailed chemical kinetic modeling. Phys Chem Chem Phys, 2002, 4: 1846–1854

Sivaramakrishnan R, Tranter R S, Brezinsky K. A high pressure model for the oxidation of toluene. P Combust Inst, 2005, 30: 1165–1173

Vanhove G, Ribaucour M, Minetti R. On the influence of the position of the double bond on the low-temperature chemistry of hexenes. P Combust Inst, 2005, 30: 1065–1072

Metcalfe W K, Pitz W J, Curran H J, et al. The development of a detailed chemical kinetic mechanism for diisobutylene and comparison to shock tube ignition times. P Combust Inst, 2007, 31: 377–384

Mehl M, Pitz W J, Westbrook C K, et al. Kinetic modeling of gasoline surrogate components and mixtures under engine conditions. P Combust Inst, 2011, 33: 193–200

Mehl M, Chen J Y, Pitz W J, et al. An approach for formulating surrogates for gasoline with application toward a reduced surrogate mechanism for CFD engine modeling. Energ Fuel, 2011, 25: 5215–5223

Andrae J, Johansson D, Björnbom P, et al. Co-oxidation in the auto- ignition of primary reference fuels and n-heptane/toluene blends. Combust Flame, 2005, 140: 267–286

Jia M, Xie M Z. A chemical kinetics model of iso-octane oxidation for HCCI engines. Fuel, 2006, 85: 2593–2604

Machrafi H, Cavadias S. Three-stage autoignition of gasoline in an HCCI engine: An experimental and chemical kinetic modeling investigation. Combust Flame, 2008, 155: 557–570

Kim Y, Min K, Kim M, et al. Development of a reduced chemical kinetic mechanism and ignition delay measurement in a rapid compression machine for CAI combustion. SAE Paper, 2007-01-0218

Togbé C, Ahmed A M, Dagaut P. Experimental and modeling study of the kinetics of oxidation of Methanol 61 Gasoline surrogate mixtures (M85 Surrogate) in a jet-stirred reactor. Energ Fuel, 2009, 23: 1936–1941

Zhang F, Shuai S, Wang Z, et al. A detailed oxidation mechanism for the prediction of formaldehyde emission from methanol-gasoline SI engines. P Combust Inst, 2011, 33: 3151–3158

Beeckmann J, Rohl O, Peters N. Experimental and numerical investigation of iso-octane, methanol and ethanol regarding laminar burning velocity at elevated pressure and temperature. SAE Paper, 2009-01-1774

Rabitz H, M Kramer, Dacol D. Sensitivity analysis in chemical kinetics. Annu Rev Phys Chem, 2003, 34: 419–461

Bhattacharjee B, Schwer D A, Barton P I, et al. Optimally-reduced kinetic models: Reaction elimination in large-scale kinetic mechanisms. Combust Flame, 2003, 135: 191–208

Wang H, Frenklach M. Detailed reduction of reaction mechanisms for flame modeling. Combust Flame, 1991, 87: 365–370

Ahmed S S, Mauß F, Moréac G, et al. A comprehensive and compact n-heptane oxidation model derived using chemical lumping. Phys Chem Chem Phys, 2007, 9: 1107–1126

Montgomery C J, Swensen D A, Harding T V, et al. A computational problem solving environment for creating and testing reduced chemical kinetic mechanisms. Adv Eng Softw, 2002, 33: 59–70

Lu T, Law C K. Linear time reduction of large kinetic mechanisms with directed relation graph: n-Heptane and iso-octane. Combust Flame, 2006, 144: 24–36

Patel A, Kong S C, Reitz R D. Development and validation of a reduced reaction mechanism for HCCI engine simulations. SAE Paper, 2004-01-0558

Brakora J L, Ra Y, Reitz R D, et al. development and validation of a reduced reaction mechanism for biodiesel-fueled engine simulations. SAE Paper, 2008-01-1378

Ra Y, Reitz R D. A reduced chemical kinetic model for IC engine combustion simulations with primary reference fuels. Combust Flame, 2008, 155: 713–738

Singh S, Kong S C, Reitz R D, et al. Modeling and experiments of dual-fuel engine combustion and emissions. SAE Transactions, 2004, 113: 124–133

Opat R, Krieger R, Reitz R D, et al. Investigation of mixing and temperature effects on HC/CO emissions for highly dilute low temperature combustion in a light duty diesel engine. SAE Paper, 2007- 01-0193

Djurisic Z M. A comprehensive chemical kinetic model for hydrocarbon combustion. Dissertation of Master Degree. Newark: University of Delaware, 1999

Ciezki H K, Adomeit G. Shock-tube investigation of self-ignition of n-heptane Air mixtures under engine relevant conditions. Combust Flame, 1993, 93: 421–433

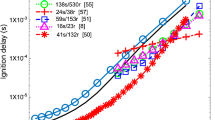

Gauthier B M, Davidson D F, Hanson R K. Shock tube determination of ignition delay times in full-blend and surrogate fuel mixtures. Combust Flame, 2004, 139: 300–311

Yahyaoui M, Dagaut P, Paillard C E, et al. Experimental and modelling study of gasoline surrogate mixtures oxidation in jet stirred reactor and shock tube. P Combust Inst, 2007, 31: 385–391

Shen H P S, Vanderover J, Oehlschlaeger M A. A shock tube study of the auto-ignition of toluene/air mixtures at high pressures. P Combust Inst, 2009, 32: 165–172

Yahyaoui M, Djebaïli-Chaumeix N, Dagaut P, et al. Kinetics of 1-hexene oxidation in a JSR and a shock tube: Experimental and modeling study. Combust Flame, 2006, 147: 67–78

Andrae J C G, Brinck T, Kalghatgi G T. HCCI experiments with toluene reference fuels modeled by a semidetailed chemical kinetic model. Combust Flame, 2008, 155: 696–712

Jerzembeck S, Peters N, Pepiot-Desjardins P, et al. Laminar burning velocities at high pressure for primary reference fuels and gasoline: Experimental and numerical investigation. Combust Flame, 2009, 156: 292–301

Held T J, Dryer F L. A comprehensive mechanism for methanol oxidation. Int J Chem Kinet, 1998, 30: 805–830

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Ling, X., Wu, F. & Yao, D. A reduced combustion kinetic model for the methanol-gasoline blended fuels on SI engines. Sci. China Technol. Sci. 59, 81–92 (2016). https://doi.org/10.1007/s11431-015-5954-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-015-5954-5