Abstract

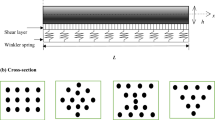

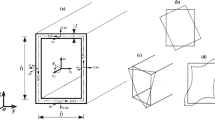

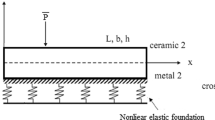

Postbuckling behavior of the 3D braided rectangular plates subjected to uniaxial compression combined with transverse loads in thermal environments is presented. Based on a micro-macro-mechanical model, a 3D braided composite may be treated as a cell system and the geometry of each cell is deeply dependent on its position in the cross-section of the plate. The material properties of the epoxy are expressed as a linear function of temperature. Uniform, linear and nonlinear temperature distributions through the thickness are involved. The lateral pressure (three types of transverse loads, i.e. transverse uniform load; transverse patch load over a central area; and transverse sinusoidal load) is first converted into an initial deflection and the initial geometric imperfection of the plate is taken into account. The governing equations are based on Reddy’s higher-order shear deformation plate theory with a von Kármán-type of kinematic nonlinearity. Two cases of the in-plane boundary conditions are also taken into account. A perturbation technique is employed to determine buckling loads and postbuckling equilibrium paths of simply supported 3D braided rectangular plates. The results reveal that the temperature rise, geometric parameter, fiber volume fraction, braiding angle, the character of the in-plane boundary conditions and different types of initial transverse loads have a significant effect on the buckling and postbuckling behavior of the braided composite plates.

Similar content being viewed by others

Abbreviations

- A ij , B ij , D ij :

-

Extensional, bending-extension coupling and bending stiffness

- E f1, E f2, G f12 :

-

Young’s modulus, shear modulus of fiber

- v f12, v f23 :

-

Poisson’s ratio of fiber

- E m , G m :

-

Young’s modulus, shear modulus of matrix

- v m :

-

Poisson’s ratio of matrix

- E ij , F ij , H ij :

-

Higher-order stiffness

- \(\bar F\), F :

-

Stress function and its dimensionless form

- a :

-

Length of a rectangular plate

- b :

-

Width of a rectangular plate

- d :

-

Short axis of cross-section of the yarn

- h :

-

Thickness of a rectangular plate

- l k , m k , n k :

-

Direction cosines of a yarn in the coordinate system

- M, N :

-

The numbers of thickness columns and wide rows of the braiding carriers

- \(\bar N_i ,\bar M_i ,\bar P_i\) :

-

In-plane stress resultants, stress couples and higher-order stress couples, \(= \sum\limits_{k = 1}^m {\int_{t_k }^{t_{k + 1} } {\sigma _i \left( {1,Z,Z^2 } \right)dZ} }\)

- \(\bar Q_{ij}\) :

-

The transformed elastic constants

- H :

-

Pitch length

- V f :

-

Fiber volume fractions

- V m :

-

Matrix volume fractions

- \(\bar U,\bar V\) :

-

Displacement components in the X and Y directions

- \(\bar W\), W :

-

Deflection of plate and its dimensionless form

- β :

-

Inclination angle between the projection of yarn axis on the Y′O′Z′ plane and the Y′-axis

- γ :

-

Braiding angle between the yarn axis and the X′-axis

- θ :

-

Surface braiding angle

- φ i :

-

Solid cross-sectional orient angle of the yarn

- \(\bar \Psi _X ,\bar \Psi _Y\) :

-

Rotations of the normals about the X and Y axes

- Ψ x , Ψ y :

-

Dimensionless forms of \(\bar \Psi _X\) and \(\bar \Psi _Y\)

References

Mouritz A P, Bannister M K, Falzon P J, et al. Review of applications for advanced three-dimensional fibre textile composites. Compos A Sci, 1999, 30: 1445–1461

Gong J C, Sankar B V. Impact properties of three-dimensional braided graphite/epoxy composites. J Compos Mater, 1991, 25: 715–731

Kharazi M, Ovesy H R, Taghizadeh M. Buckling of the composite laminates containing through-the-width delaminations using different beam theories. Compos Struct, 2010, 92: 1176–1183

Xu K, Xu X W. Finite element analysis of mechanical properties of 3D five-directional braided composites. Mater Sci Eng A, 2008, 487: 499–509

Yang J M, Ma C L, Chou T W. Fibre inclination model of three dimensional textile structural composites. J Compos Mater, 1986, 20: 472–484

Kalidindi S R, Abusafieh A. Longitudinal and transverse moduli and strengths of low angle 3-D braided composites. J Compos Mater, 1996, 30: 885–905

Chen Z R, Zhu D C, Lu M, et al. A homogenisation scheme and its application to evaluation of elastic properties of three-dimensional braided composites. Compos B Eng, 2001, 32: 67–86

Sagar T V, Potluri P, Hearle J W S. Mesoscale modelling of interlaced fibre assemblies using energy method. Comput Mater Sci, 2003, 28: 49–62

Shokrieh M M, Mazloomi M S. A new analytical model for calculation of stiffness of three-dimensional four-directional braided composites. Compos Struct, 2012, 94: 1005–1015

Goyal D, Tang X D, Whitcomb J D. Effect of various parameters on effective engineering properties of 2×2 braided composites. Mech Adv Mater Struct, 2005, 12: 113–128

Sun X K, Sun C J. Mechanical properties of three-dimensional braided composites. Compos Struct, 2004, 65: 485–492

Aboudi J. The generalized method of cells and high-fidelity generalized method of cells micromechanical models-a review. Mech Adv Mater Struct, 2004, 11: 329–366

Yu X G, Cui J Z. The prediction on mechanical properties of 4-step braided composites via two-scale method. Compos Sci Technol, 2007, 67: 471–480

Potluri P, Manan A, Francke M. Flexural and torsional behaviour of biaxial and triaxial braided composite structures. Compos Struct, 2006, 75: 377–386

Reissner E. The effect of transverse shear deformation on the bending of elastic plates. J Appl Mech, 1945, 67: 67–77

Mindlin R. Influence of rotary inertia and shear on flexural motions of isotropic elastic plates. J Appl Mech, 1951, 18: 31–38

Chen L W, Doong J L. Postbuckling behavior of a thick plate. AIAA J, 1983, 21: 1157–1161

Librescu L, Stein M. Postbuckling of shear deformable composite flat panels taking into account geometrical imperfections. AIAA J, 1992, 30: 1352–1360

Reddy J N, Khdeir A A. Buckling and vibration of laminated composite plates using various plate theories. AIAA J, 1989, 27: 1808–1817

Li Z M, Zhu P, Lin Z Q. Nonlinear bending behavior of 3D braided rectangular plates subjected to transverse loads in thermal environments. Arch Appl Mech, 2011, 81: 585–603

Li Z M. Thermal postbuckling behavior of 3D braided rectangular plates. J Therm Stresses, 2011, 34: 626–649

Li Z M, Yang D Q. Thermal postbuckling analysis of 3D braided composite cylindrical shells. J Mech, 2010, 26: 113–122

Li Z M, Gu W, Zhao Y X. Postbuckling behavior of 3D braided rectangular plates subjected to biaxial compression. J Aerosp Eng, 2012, 25: 680–690

Reddy J N. Mechanics of Laminated Composite Plates: Theory and Analysis. Boca Raton: CRC Press, 1996. 591–598

Shen H S. Kármán-type equation for a higher-order shear deformation plate theory and its use in the postbuckling analysis. Appl Math and Mech (Engl Ed), 1997, 18: 1137–1152

Shen H S. Hygrothermal effects on the postbuckling of shear deformable laminated plates. Int J Mech Sci, 2001, 43: 1259–1281

Karami G, Garnich M. Micromechanical study of thermoelastic behavior of composites with periodic fiber waviness. Compos B Eng, 2005, 36: 241–248

Kalidindi S R, Abusafieh A. Longitudinal and transverse moduli and strengths of low angle 3-D braided composites. J Compos Mater, 1996, 30: 885–905

Chen Z R, Zhu D C, Lu M, et al. Evaluation of elastic properties of 3-D (4-step) regular braided composites by a homogenisation method. Compos Struct, 1999, 47: 477–482

Yang J, Huang X L. Dynamic stability behavior of 3D braided composite plates integrated with piezoelectric layers. J Compos Mater, 2009, 43: 2223–2238

Shapery R A. Thermal expansion coefficient of composite materials based on energy principles. J Compos Mater, 1968, 2: 380–404

Adams D F, Miller A K. Hygrothermal microstresses in a unidirectional composite exhibiting inelastic materials behavior. J Compos Mater, 1977, 11: 285–299

Islam M R, Sjoind S G, Paramil A. Finite element analysis of linear thermal expansion coefficients of unidirectional cracked composites. J Compos Mater, 2001, 35: 1762–1776

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chu, G., Li, Z. Postbuckling behavior of 3D braided rectangular plates subjected to uniaxial compression and transverse loads in thermal environments. Sci. China Technol. Sci. 57, 1439–1453 (2014). https://doi.org/10.1007/s11431-014-5568-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5568-3