Abstract

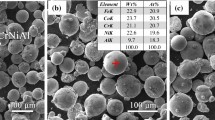

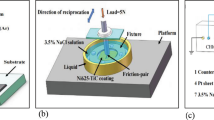

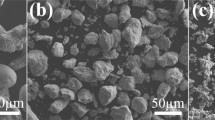

Mo-based alloys are widely used for their excellent wear and corrosion resistance as well as high temperature resistance. Mo-NiCrBSi and Mo-Ni alloy coatings were prepared on 1020 water wall tube by laser cladding technology in the present study. The microstructure and phase compositions were analyzed by means of the scanning electron microscopy (SEM), energy-dispersive spectroscopy (EDS) and X-ray diffractometry (XRD). The corrosion properties of the coatings were evaluated by an electrochemical experiment at room temperature in 3.5 wt.% NaCl electrolyte. With increasing content of Mo, the structure homogeneity in Mo-Ni coatings deteriorated, the grain size increased, the average hardness and the corrosion resistance declined, due to the more content of harmful phases. Compared to the Mo-Ni coatings, the overall performance was better for the Mo-NiCrBSi, which had the higher hardness contributed by the element B and Si as well as the better corrosion resistance due to the addition of Cr.

Similar content being viewed by others

References

Niedbala J. Surface morphology and corrosion resistance of electrodeposited composite coatings containing polyethylene or polythiophene in Ni-Mo base. Bull Mater Sci, 2011, 34: 993–996

Rodriguez J, Martin A, Fernández R, et al. An experimental study of the wear performance of NiCrBSi thermal spray coatings. Wear, 2003, 255: 950–955

Grigorescu I C, Di Rauso C, Drira-Halouani R, et al. Phase characterization in Ni alloy-hard carbide composites for fused coatings. Surf Sci Technol, 1995, 494: 76–77

Tobar M J, Alvarez C, Amado J M, et al. Morphology and characterization of laser clad composite NiCrBSi-WC coatings on stainless steel. Surf Coat Technol, 2006, 200: 6313–6317

Navas C, Colaço R, De Damborenea J, et al. Abrasive wear behaviour of laser clad and flame sprayed-melted NiCrBSi coatings. Surf Coat Technol, 2006, 200: 6854–6862

Krishnaveni K, Sankara Narayanan T S N, Seshadri S K. Electroless Ni-B coatings: preparation and evaluation of hardness and wear resistance. Surf Coat Technol, 2005, 190: 115–121

Oversm M P, Harris S J, Waterhouse R B. Wear of Materials. In: Ludema K C, Glaeser W A, Rhee S K, eds. ASME. New York, 1979: 379

Beltowska-Lehman E, Bigos A, Indyka P, et al. Electrodeposition and characterisation of nanocrystalline Ni-Mo coatings, Surf Coat Technol, 2012, 211: 67–71

Han Q, Cui S, Pu N W, et al. A study on pulse plating amorphous Ni-Mo alloy coating used as HER cathode in alkaline medium. Int J Hydrogen Energy, 2010, 35: 5194–5201

Huot J Y, Trudeau M L, Schulz R. Low hydrogen over potential nano-crystalline Ni-Mo cathodes. J Electrochem Soc, 1991, 138: 1316–1321

Yagi S, Kawakami A, Murase K, et al. Ni-Mo alloying of nickel surface by alternating pulsed electrolysis using molybdenum (VI) baths. Electrochim Acta, 2007, 52: 6041–6051

Sanches L S, Domingues S H, Claudia E B, et al. Characterisation of electrochemically deposited Ni-Mo alloy coatings. Electrochem Commun, 2004, 6: 543–548

Abdel-Karima R, Halim J, El-Raghy S, et al. Surface morphology and electrochemical characterization of electrodeposited Ni-Mo nanocomposites as cathodes for hydrogen evolution. J Alloys Compd, 2012, 530: 85–90

Kurz S J B, Ensslen C, Welzel U, et al. The thermal stability of Ni-Mo and Ni-W thin films: Solute segregation and planar faults. Scripta Mater, 2013, 69: 65–68

Banerjee R, Brice C A, Banerjee S, et al. Microstructural evolution in laser deposited Ni-25at.% Mo alloy. Mater Sci Eng A, 2003, 347: 1–4

Rodríguez-Valdez L M, Estrada-Guel I, Almeraya-Calderón F, et al. Electrochemical performance of hydrogen evolution reaction of Ni-Mo electrodes obtained by mechanical alloying, Int. J. Hydrogen Energy. 2004, 29: 1141–1145

Qin Z R, Li L S, Sun J F, et. al. Studies on the passivation film of cast nickel-molybdenum alloys in concentrated hydrochloric acid. Shanghai Nonferrous Metals, 1998, 19: 154–158

Chen J J. Properties and container manufacturing processing characteristics of Hastelloy B-3-nickel-molybdenum alloys. Manufacture installation, 2004, 11: 32–35

Kawashima A, Akiyama E, Habazaki H, et al. Characterization of sputter-deposited Ni-Mo and Ni-W alloy electrocatalysts for hydrogen evolution in alkaline solution. Mater Sci Eng A, 1997, 226–228: 905–909

Highfiled J G, Claude E. Electrocatalytic synergism in Ni/Mo cathodes for hydrogen evolution in acid medium: A new model. Electrochim Acta, 1999, 44: 2805–2814

Yang S, Liu W J, Zhong M L, et al. TiC reinforced composite coating produced by powder feeding laser cladding. Mater Lett, 2004, 58: 2958–2962

Sun R L, Tang Y, Yang X J. Microstructure and tribological properties of in-situ synthesized TiB2-TiC/Ni based composite coating by laser cladding. 14th Congress of International Federation for Heat Treatment and Surface Engineering, Vols. 1 and 2, Proceedings, 2004, 1000–1003

Niranatlumpong P, Koiprasert H. The effect of Mo content in plasma-sprayed Mo-NiCrBSi coating on the tribological behavior. Surf Coat Tech, 2010, 205: 483–489

Yang G, Liu Z D, Wang Y T. Influence of molybdenum on the microstructure and mechanical properties of TiC-TiB2 reinforced metal matrix composite coatings. Sci China Tech Sci, 2013, 56: 1008–1016

Ge Y L, Deng D W, Lu J, et al. Study on microstructure and microhardness of two Ni-Cr-B-Si based alloy plasma surfacing coatings. Surface tech, 2012, 41: 5–8

Cui Z Q, Wang W X, Ji J C, et al. Microstructure and properties of laser cladding Ni-Cr-B-Si alloy coating on surface of 15CrMo steel. Transactions of materials and heat treatment, 2011, 32: 139–143

Zhang W, Shi S Q, Chen Y X, et al. Microstructure and properties of laser cladding Ni-Cr-B-Si thermal fatigue resistant alloy. Heat treatment of metals, 2012, 37: 103–105

Wang L Z, Xiang M, Gu S H, et al. Open-circuit voltage and its influencing factors. Battery Bimonthly, 1999, 29: 157–160

Zhang Q k, Lin N, He Y H. Effects of Mo additions on the corrosion behavior of WC-TiC-Ni hardmetals in acidic solutions. Int J Refract Met Hard Mater, 2013, 38: 15–25

Hoog C, Birbilis N, Estrin Y. Corrosion of pure Mg as a function of grain size and processing route. Adv Eng Mater 2008, 6: 579–582

Hochstrasser K S, Mueller Y, Latkoczy C, et al. Analytical characterization of the corrosion mechanisms of WC-Co by electrochemical methods and inductively coupled plasma mass spectroscopy. Corros Sci, 2007, 49: 2002–2020

Sutthiruangwong S, Mori G. Corrosion properties of Co-based cemented carbides in acidic solutions. Int J Refract Met Hard Mater 2003, 21: 135–145

Tan W, Chen C, Wang M P, et al. Study on influence of different factors on the plastic and brittle properties of molybdenum and molybdenum alloys. Materials Review, 2007, 21: 80–83

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., Liu, Z. & Wang, Y. Microstructure and corrosion properties of laser cladding MoNi based alloy coatings. Sci. China Technol. Sci. 57, 980–989 (2014). https://doi.org/10.1007/s11431-014-5512-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5512-6