Abstract

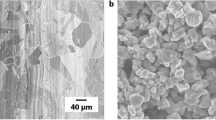

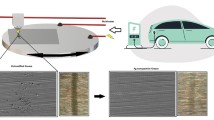

The influence of duplex surface treatments consisting of a DC-pulsed plasma nitriding process and subsequent coatings of CrN and TiAlN deposited by physical vapor deposition (PVD) on AISI H13 tool steel was studied in this article. The treated samples were characterized using metallographic techniques, SEM, EDS, and microhardness methods. Hydro-abrasive erosion wear tests were performed in a specifically designed wear tester in which the samples were rotated in a wear tank containing a mixture of distilled water and ceramic abrasive chips with a fixed rotational speed. The wear rates caused by the abrasive particle impacts were assessed based on accumulated weight loss measurements. The worn surfaces were also characterized using optical microscopy, SEM, and EDS. Microhardness measurements indicated a significant increase in the surface hardness of the duplex-treated samples. The surfaces of the samples with the TiAlN coating were approximately 15 times harder than that of the untreated samples and 3 times that of the plasma nitrided samples. Hydro-abrasive erosion wear results showed that the duplex surface treatments, especially the CrN coating, displayed the highest erosion wear resistance.

Similar content being viewed by others

References

Kulu P, Veinthal J, Koo H, et al. Mechanism of abrasion erosion wear of thermal sprayed coatings. In: Miannay D, Costa P, François D, et al. eds. Proceedings of the Conference EUROMAT 2000 on Advances in Mechanical Behaviour, Plasticity and Damage. Tours, France: Elsevier Science Ltd, 2000. 651–656

Kulu P, Halling J. Recycled hard metal-base wear resistance composite coatings. J Therm Spray Technol, 1998, 7: 173–178

Suchánek J, Kuklík V, Zdravecká E. Influence of microstructure on erosion resistance of steels. Wear, 2009, 267: 2092–2099

Yigit K, Aydin H. Hydro-abrasive erosion resistance of C45 steel in different heat-treated states on a designed wear test apparatus. Mater Test, 2010, 52: 323–331

Zhang D, Zhang X. Laser cladding of stainless steel with Ni-Cr3C2 and Ni-WC for improving erosive-corrosive wear performance. Surf Coat Technol, 2005, 190: 212–217

Shen S, Meng Y. Adhesive and corrosive wear at microscales in different vapor environments. Friction, 2013, 1: 72–80

Hancock P. The use of laboratory and rig tests to simulate gas turbine corrosion problems. Corrosion Sci, 1982, 22(1): 51–65

Lin N M, Xie F Q, Zou J J, et al. Slurry erosion behaviors of P110 steel and chromizing coating in liquid-solid two-phase flow. Sci China Tech Sci, 2013, 56: 1415–1423

Alsaran A, Çelik A, Çelik C, et al. Optimization of coating parameters for duplex treated AISI 5140 steel. Mater Sci Eng A, 2004, 371: 141–148

Batista J C A, Joseph M C, Godoy C, et al. Micro-abrasion wear testing of PVD TiN coatings on untreated and plasma nitrided AISI H13 steel. Wear, 2001, 249: 971–979

Bell T, Dong H, Sun Y. Realizing the potential of duplex surface engineering. Tri Int, 1998, 31: 127–137

Wierzchon T. Structure and properties of multicomponent and composite layers produced by combined surface engineering methods. Surf Coat Technol, 2003, 180-181: 458–464

Björk T, Westergard R, Hogmark S, et al. Physical vapour deposition duplex coatings for aluminium extrusion dies. Wear, 1999, 225-229: 1123–1130

Bader M, Spies H J, Hock K, et al. Properties of duplex treated (gas-nitriding and PVD-TiN, -Cr2N) low alloy steel. Surf Coat Technol, 1998, 98: 891–896

Sun Y, Bell T. The role of oxidation in the wear of plasma nitrided and PVD TiN coated steel. Wear, 1993, 166: 119–125

Stappen M V, Kerkhofs M, Quaeyhaegens C, et al. Introduction in industry of a duplex treatment consisting of plasma nitriding and PVD deposition of TiN. Surf Coat Technol, 1993, 62: 655–661

Recco A A C, López D, Bevilacqua A F, et al. Improvement of the slurry erosion resistance of an austenitic stainless steel with combinations of surface treatments: Nitriding and TiN coating. Surf Coat Technol, 2007, 202: 993–997

Podgornik B, Vižintin J, Wänstrand O, et al. Tribological properties of plasma nitrided and hard coated AISI 4140 steel. Wear, 2001, 249: 254–259

Michler T, Grischke M, Bewilogua K, et al. Properties of duplex coatings prepared by plasma nitriding and PVD Ti-C:H deposition on X20Cr13 ferritic stainless steel. Thin Solid Films, 1998, 322: 206–212

Chang S H, Lin Y K, Huang K T. Study on the thermal erosion, wear and corrosion behaviors of TiAlN/oxynitriding duplex-treated AISI H13 alloy steel. Surf Coat Technol, 2012, 207: 571–578

Chang S H, Huang K T, Wang Y H. Effects of thermal erosion and wear resistance on AISI H13 tool steel by various surface treatments. Mater Trans, 2012, 53: 745–751

Navinsek B, Panjan P, Urankar I, et al. Improvement of hot-working processes with PVD coatings and duplex treatment. Surf Coat Technol, 2001, 142-144: 1148–1154

Rodríguez E, Flores M, Pérez A, et al. Erosive wear by silica sand on AISI H13 and 4140 steels. Wear, 2009, 267: 2109–2115

Gupta R, Singh S N, Seshadri V. Prediction of uneven wear in a slurry pipeline on the basis of measurements in a pot tester. Wear, 1995, 184: 169–178

Clark H M. The influence of flow field in slurry erosion. Wear, 1993, 152: 223–240

Elkholy A. Prediction of abrasion wear for slurry pump materials. Wear, 1983, 84: 39–49

Mahboubi F, Fattah M. Duplex treatment of plasma nitriding and plasma oxidation of plain carbon steel. Vacuum, 2005, 79: 1–6

Aydin H, Bayram A, Topcu S. Effect of different nitriding processes on the friction coefficient of 304 austenitic and 420 martensitic stainless steels. Ind Lubr Tribol, 2013, 65: 27–36

Usta M, Oney I, Yildiz M, et al. Nitriding of AISI 316L surgical stainless steel in fluidized bed reactor. Vacuum, 2004, 73: 505–510

Vandendael I, Steenhaut O, Hubin A, et al. AES analysis of nitride layers on steel with target factor analysis. Surf Coat Technol, 2004, 30: 1093–1097

Zhu X, Yan Z, Xu J. Ion penetration and diffusion technique at atmospheric pressure. Surf Coat Technol, 2007, 201: 5435–5437

Aydin H, Bayram A, Topcu S. Friction characteristics of nitrided layers on AISI 430 ferritic stainless steel obtained by various nitriding processes. Mater Sci-Medzg, 2013, 19: 19–24

Chang S H, Tang T P, Chen Y C, et al. Enhancement of erosion resistance on AISI H13 tool steel by oxynitriding treatment. ISIJ Int, 2009, 49: 421–424

Chim Y C, Ding X Z, Zeng X T, et al. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films, 2009, 517: 4845–4849

Ding X Z, Tan A L K, Zeng X T, et al. Corrosion resistance of CrAlN and TiAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films, 2008, 516: 5716–5720

Aharonov R R, Coll B F, Fontana R P. Properties of chromium nitride coatings deposited by cathodic arc evaporation. Surf Coat Technol, 1993, 61: 223–226

Pinedo C E, Monteiro W A. Surface hardening by plasma nitriding on high chromium alloy steel. J Mater Sci Lett, 2001, 20: 147–149

Gabriel B M. Synthesis-structure-property-performance relationships of TiN, CrN, and nanolayer (Ti,Cr)N coatings deposited by cathodic arc evaporation for hard particle erosion resistance. Dissertaition for Master Degree. The Pennsylvania State University, 2009

Grötzbach M. Solid Particle Erosion and Erosion Corrosion of Materials. Ohio: ASM, 1995

Deng J X, Wu F F, Lian Y S, et al. Erosion wear of CrN, TiN, CrAlN, and TiAlN PVD nitride coatings. Int J Refract Met Hard Mat, 2012, 35: 10–16

Deng J X. Erosion wear of boron carbide nozzles by abrasive air-jets. Mater Sci Eng A, 2005, 408: 227–233

Wood R J K, Wheeler D W, Lejeau D C. Sand erosion performance of CVD boron carbide coated tungsten carbide. Wear, 1999, 233–235: 134–150

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tutar, M., Aydin, H., Durmus, A. et al. The hydro-abrasive erosion wear behavior of duplex-treated surfaces of AISI H13 tool steel. Sci. China Technol. Sci. 57, 1040–1051 (2014). https://doi.org/10.1007/s11431-014-5510-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5510-8