Abstract

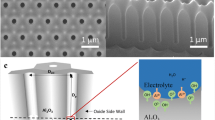

The porous anodic alumina membranes (PAAMs) have been successfully used as templates for the fabrication of functional nano-materials due to their outstanding regularity and physicochemical properties. In this paper, a transparent double-sided anodic alumina membrane with ultra-thin aluminum substrate was fabricated with the three-step anodic oxidation method in the oxalic acid electrolyte. The characters such as the top-surface morphology, membrane thickness, and depth of nanopores of this three-layer (Al2O3-Al-Al2O3) sandwiched nano-structure were controllable through regulating the main anodic oxidation conditions, e.g., anodic oxidation time of various steps, coating remove process. The experiments data revealed that the aluminum substrate is exponential declined with the oxidation time when it was approximately reduced by a few micrometers. This new double-sided anodic alumina membrane can be used as the high-quality functional field emission materials and templates.

Similar content being viewed by others

References

Fologea D, Gershow M, Ledden B, et al. Detecting single stranded dna with a solid state nanopore. Nano Lett, 2005, 5: 1905–1909

Kim Y, Jung B, Lee H, et al. Capacitive humidity sensor design based on anodic aluminum oxide. Sensors Actuators B, 2009, 141: 441–446

Mizeikis V, Mikulskas I, Tomasiunas R, et al. Optical characteristics of two-dimensional photonic crystals in anodic aluminum oxide films. Jpn J Appl Phys, 2004, 43: 3643–3648

Dong S K, Lee H U, Kim N H, et al. Fabrication of microchannel containing nanopillar arrays using micromachined AAO (anodic aluminum oxide) mold. Microeletronic Eng, 2007, 84: 1532–1535

Che G L, Lakshmi B B, Fisher E R, et al. Carbon nanotubule membranes for electrochemical energy storage and production. Nature, 1998, 393: 346–349

Chik H, Xu J M. Nanometric superlattices: Non-lithographic fabrication, materials, and prospects. Mater Sci Eng R, 2004, 43: 103–138

Deb P, Kim H Y, Rawat V, et al. Faceted and vertically aligned gan nanorod arrays fabricated without catalysts or lithography. Nano Lett, 2005, 5: 1847–1851

Feng L., Li S H, Li Y S, et al. Super-hydrophobic surfaces: From natural to artificial. Adv Mater, 2002, 14: 1857–1860

Ran C B, Ding G Q, Liu W C, et al. Wetting on nanoporous alumina surface: Transition between wenzel and cassie states controlled by surface structure. Langmuir, 2008, 24: 9952–9955

Li Q, Wang K G, Xi D, et al. A kind of synthetic nanopillar arrays for studying single biomolecule. J Nanosci Nanotechnol, 2010, 10: 7447–7450

Wang K, Dang W, Xi D, et al. Hybridised functional micro-and nanostructure for studying the kinetics of a single biomolecule. Micro Nano Lett, 2011, 6: 292–295

Hui D, Wang K G, Zhao X J, et al. The competition of the retraction and capillary forces during the DNA molecules moving within channels. Key Eng Mat, 2011, 483: 331–335

Kondo T, Juodkazis S, Misawa H. Reduction of capillary force for high-aspect ratio nanofabrication. Appl Phys A, 2005, 81: 1583–1586

Shirota Y, Kageyama H. Charge carrier transporting molecular materials and their applications in devices. Chem Rev, 2007, 107: 953–1010

Haberkorn N, Gutmann J S, Theato P. Template-assisted fabrication of free-standing nanorod arrays of a hole-conducting cross-linked triphenylamine derivative: Toward ordered bulk-heterojunction solar cells. ACS Nano, 2009, 3: 1415–1422

Masuda H, Fukuda K. Ordered metal nanohole arrays made by a two-step replication of honeycomb structures of anodic alumina. Science, 1995, 268: 1466–1468

Mikulskas I, Juodkazis S, Tomašiūnas R, et al. Aluminum oxide photonic crystals grown by a new hybrid method. Adv Mater, 2001, 13: 1574–1577

Kwon N, Kim K, Heo J, et al. Fabrication of ordered anodic aluminum oxide with matrix arrays of pores using nanoimprint. J Vac Sci Technol A, 2009, 27: 803–807

Chen B, Lu K, Tian Z P. Novel patterns by focused ion beam guided anodization. Langmuir, 2011, 27: 800–808

Chen B, Lu K. Moiré pattern nanopore and nanorod arrays by focused ion beam guided anodization and nanoimprint molding. Langmuir, 2011, 27: 4117–4125

Kasi A K, Kasi J K, Afzulpurkar N, et al. Bending and branching of anodic aluminum oxide nanochannels and their applications. J Vac Sci Technol B, 2012, 30: 031805

Hsieh C L, Lo P H, Fang W. Dual-layer nanoporous anodic aluminum oxide with embedded electrodes for capacitive relative humidity sensor. The 17th International Conference, Barcelona: IEEE, 2013, 2572–2575

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Wang, K., Gao, Z. et al. A kind of double-sided porous anodic alumina membrane fabricated with the three-step anodic oxidation method. Sci. China Technol. Sci. 57, 293–297 (2014). https://doi.org/10.1007/s11431-014-5466-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5466-8