Abstract

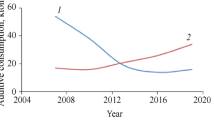

Both the academic society and the industry are hunting for new energy forms for the future. However, the world should not forget the conventional technologies that contribute to the sustainable society by technical innovations. Among them, lubrication plays a significant role in energy saving and in low CO2 emission by increasing the fuel efficiency and by prolonging the service life of machines. With the advance of novel synthetic approaches, and nanoscience and technologies, novel lubrication oils and additives and their formulations are being developed to reduce friction and wear, and novel surface treatment routes and surface coatings are invented and provide more efficient lubrication. These technologies create tremendous chances for machines to work more efficiently with low energy consumption. Here we review the recent progresses and challenges associated with some novel lubrication techniques that include novel surface treatment (such as texturing, high-performance nanocomposite coatings, adapting coating), tribology design (solid and liquid lubrication), energy-conserving engine oil and novel lubricants and formula (such as ionic liquids, low S, P content additives) which are to be adopted to enhance the fuel efficiency to achieve energy saving and low carbon emission. There is increased demand to replace fossil lubricants by degradable green lubricants. Specially designed coatings can reduce drag significantly during navigation of both airplanes and ships. All these aspects will be also reviewed in the paper.

Similar content being viewed by others

References

British Petroleum (BP), Statistical Review of World Energy.June 2011, page 42 http://www.bp.com/assets/bp_internet/globalbp/globalbp_uk_english/reports_and_publications/statistical_energy_review_2011/STAGING/local_assets/pdf/statistical_review_of_world_energy_full_report_2011

Liu G F, Chen X L, Riedel R, et al. Green technology foresight on automobile technology in China. Technol Anal Strat, 2011, 23(6): 683–696

Shafiullah G M, Amanullah M T O, Shawkat Ali A B M, et al. Prospects of renewable energy-A feasibility study in the Australian context. Renew Energ, 2012, 39(1): 183–197

Poizot P, Dolhem F. Clean energy new deal for a sustainable world: from non-CO2 generating energy sources to greener electrochemical storage devices. Energ Environ Sci, 2011, 4(6): 2003–2019

Okkerse C, Bekkum H V. From fossil to green. Green Chem, 1999, 1(2): 107–114

Jacobson M Z. Review of solutions to global warming, air pollution, and energy security. Energ Environ Sci, 2009, 2: 148–173

Bhushan B. Introduction to Tribology. New York: John Wiley & Sons Inc, 2002

Xue Q J, Zhang Y Z, Li J. Development of industrial tribology in China. Tribol Online, 2007, 2(1): 10–13

Zhou F, Liang Y M, Liu W M. Ionic liquid lubricants: designed chemistry for engineering applications. Chem Soc Rev, 2009, 38(9): 2590–2599

Jost H P. Lubrication (Tribology), Education and Research, (Jost Report). Department of Education and Science, HMSO. London, 1966

Jost H P, Schofield J. Energy saving through tribolog: A technoeconomic study. Proc lnstn Mech Engrs, 1981, 195: 151–173

Nosonovsky M, Bhushan B. Green tribology: principles, research areas and challenges. P Roy Soc A-Math Phy, 2010, 368(1929): 4677–4694

Hamrock B J, Schmid S R, Jacobson B O. Fundamentals of Fluid Film Lubrication. 2nd ed. Boca Raton: CRC Press Inc., 2004

Dowson D. History of Tribology. 2nd ed. London: Professional Engineering Publishing, 1998

Mortier R M, Orzulik S T. Chemistry and Technology of Lubricants. 2nd ed. New York: Blackie Academic and Professional, 1997

Boyde S. Green lubricants. Environmental benefits and impacts of lubrication. Green Chem, 2002, 4(4): 293–307

Wilk M A, Abraham W D, Dohner B R. An investigation into the effect of zinc dithiophoaphate on ASTM sequence VIA fuel economy. SAE Technical Paper 961914, 1996, doi:10.4271/961914

Rizvi S Q A. A Comprehensive Review of Lubricant Chemistry, Technology, Selection, and Design. Baltimore: ASTM International, 2009

Watanabe H I, Dam W V, Parsons G, et al. A fuel economy study in heavy duty diesel engine lubricants. Lubrication Oil, 2011, 26(4): 10–17

Wu X L. Lubrication Design Handbook. Beijing: Chemical Industry Press, 2006

Bartzl W J. Gear oil influences on efficiency of gear and fuel economy of cars. P I Mech Eng D-J Aut, 2000, 214(2): 189–196

Gunstone F. Fatty Acid and Lipid Chemistry. London: Blackie Academic and Professional, 1996

Archbutt L, Deeley R M. Lubrication and Lubricants. 5th ed. London: Charles Griffin & Co, 1927

Wang Y M, Wang H. Lubricating Materials and Lubrication Technology. Beijing: Chemical Industry Press, 2005

Merryweahter S, Zweifel D. New oil soluble polyalkylene glycos for energy saving lubricant application. In: Proc the 4th World Tribology Congress, Kyoto, Japan, 2009. 37

Anastopoulos G, Kalligeros S, Schinas P, et al. Effect of dicarboxylic acid esters on the lubricity of aviation kerosene for use in CI engines. Friction, 2013, 3: 271–278

Wu R, Knapik M. Determination and application of stribeck curve in development of steel cold rolling lubricants. Iron Steel Technology, AIS Tech 2009, 2010, 2: 52–57

Rudnick L R, Balusamy V. Synthetic lubricants and high-performance functional fluids. New York: Marcel Dekker, Inc, 2004

Thom R, Kollman K, Frend M. Extended oil drain intervals: Conservation of resources or reduction of engine life. SAE International Congress, Detroit, Feb. 27–March 2, 1996

Reported as Lube Tech Report, Fuels Lubes Int, 1995.11–13

Rudnick L R. Lubricant Additives: Chemistry and Applications. New York: Marcel Dekker, Inc., 2003

Benda R, Bullen J. Polyalphaolefins-base fluids for high-performance lubricants. J Synth Lubr, 1996, 13(1): 41–57

Coffin P S, Lindsay C M, Mills A J, et al. The application of synthetic fluids to automotive lubricant development: trends today and tomorrow. J Synth Lubr, 1990, 7: 123–143

Dressler H, Meilus A A. Synthetic oils. U. S. 4604491, 1986

Bridwell B W, Johnson C E. Mono-alkylation of naphthalene. U. S. 3959399, 1976

Mc Gulre S E, Riddle J L, Nicks G E, et al. Prepartion of synthetic hydrocarbon lubricants. U. S. 3909432, 1975

Ye C F, Liu W M, Chen Y X, et al. Room-temperature ionic liquids: a novel versatile lubricant. Chem Commun, 2001, 21: 2244–2245

Earle M J, Seddon K R. Ionic liquids green solvents for the future. Pure Appl Chem, 2000, 72(7): 1391–1398

Hagiwara R, Ito Y. Room temperature ionic liquids of alkylimidazolium cations and fuoroanions. J Fluorine Chem, 2000, 105(2): 221–227

Lu Q M, Wang H Z, Ye C F, et al. Room temperature ionic liquid 1-ethyl-3-hexylimidazolium-bis(trifluoromethylsulfonyl)-imide as lubricant for steel-steel contact. Tribol Int, 2004, 37(7): 547–552

Weng L J, Liu X Q, Liang Y M, et al. Effect of tetraalkylphosphonium based ionic liquids as lubricants on the tribological performance of a steel-on-steel system. Tribol Lett, 2006, 26(1): 11–17

Xia Y Q, Wang S J, Zhou F, et al. Tribological properties of plasma nitrided stainless steel against SAE52100 steel under ionic liquid lubrication condition. Tribol Int, 2006, 39(7): 635–640

Torimoto T, Tsuda T, Okazaki K I, et al. New frontiers in materials science opened by ionic liquids. Adv Mater, 2010, 22(11): 1196–1221

Minami I, Inada T, Sasaki R, et al. Tribo-chemistry of phosphoniumderived ionic liquids. Tribol Lett, 2010, 40(2): 225–235

Minami I. Ionic liquids in tribology. Molecules, 2009, 14(6): 2286–2305

Jiménez A E, Bermúdez M D. Ionic liquids as lubricants of titanium Steel contact. Part 2: Friction, wear and surface interactions at high temperature. Tribol Lett, 2009, 37(2): 431–443

Bermúdez M D, Jiménez A E, Sanes J, et al. Ionic liquids as advanced lubricant fluids. Molecules, 2009, 14(8): 2888–2908

Yu B, Zhou F, Pang C J, et al. Tribological evaluation of α, ω′-diimidazoliumalkylene hexafluorophosphate ionic liquid and benzotriazole as additive. Tribol Int, 2008, 41(8): 797–801

Yao M H, Liang Y M, Xia Y Q, et al. High-temperature tribological properties of 2-substituted imidazolium ionic liquids for Si3N4-steel contacts. Tribol Lett, 2008, 32(2): 73–79

Minami I, Kita M, Kubo T, et al. The tribological properties of ionic liquids composed of trifluorotris(pentafluoroethyl) phosphate as a hydrophobic anion. Tribol Lett, 2008, 30(3): 215–223

Jiménez A E, Bermúdez M D. Ionic liquids as lubricants of titaniumsteel contact. Tribol Lett, 2008, 33(2): 111–126

Mu Z G, Zhou F, Zhang S X, et al. Effect of the functional groups in ionic liquid molecules on the friction and wear behavior of aluminum alloy in lubricated aluminum-on-steel contact. Tribol Int, 2005, 38(8): 725–731

Wang H Z, Lu Q M, Ye C F, et al. Friction and wear behaviors of ionic liquid of alkylimidazolium hexafluorophosphates as lubricants for steel/steel contact. Wear, 2004, 256(1–2): 44–48

Liu W M, Ye C F, Gong Q Y, et al. Tribological performance of room-temperature ionic liquids as lubricant. Tribol Lett, 2002, 13(2): 81–85

Song Z H, Liang Y M, Fan M J, et al. Lithium-based ionic liquids as novel lubricant additives for multiply alkylated cyclopentanes (MACs). Friction, 2013, 3: 222–231

Qu J, Blau P J, Dai S, et al. Ionic liquids as novel lubricants and additives for diesel engine applications. Tribol Lett, 2009, 35(3): 181–189

Qu, J, Truhan J J, Dai S, et al. Ionic liquids with ammonium cations as lubricants or additives. Tribol Lett, 2006, 22(3): 207–214

Predel T, Pohrer B, Schlücker E. Ionic liquids as alternative lubricants for special applications. Chem Eng Technol, 2010, 33(1): 132–136

Bronshteyn L A, Kreiner J H. Energy efficiency of industrial oils. Tribol Trans, 1999, 42(4): 771–776

Vipper A B, Bartz W, Karaulov A K, et al. Antifriction action of lubricant additives. Lubr Sci, 1995, 7(3): 247–259

Martin J M, Matta C, Bouchet M I D B, et al. Mechanism of friction reduction of unsaturated fatty acids as additives in diesel fuels. Friction, 2013, 3: 252–258

Zhang J, Jin Y L, Ma X G, et al. Modern Lubrication Technique. Beijing: Metallurgical Industry Press, 2008. 58

Jiménez A E, Bermúdez M D, Carrion F, et al. Room temperature ionic liquids as lubricant additives in steel-aluminium contacts: Influence of sliding velocity, normal load and temperature. Wear, 2006, 261(3–4): 347–359

Jiménez A E, Bermúdez M D. Imidazolium ionic liquids as additives of the synthetic ester propylene glycol dioleate in aluminium-steel lubrication. Wear, 2008, 265(5-6): 787–798

Priest M, Fox M F. Tribological properties of ionic liquids as lubricants and additives. Part 1: Synergistic tribofilm formation between ionic liquids and tricresyl phosphate. P I Mech Eng J-J Eng, 2008, 222(3): 291–303

Battez A H, González R, Viesca J L, et al. Tribological behaviour of two imidazolium ionic liquids as lubricant additives for steel/steel contacts. Wear, 2009, 266(11-12): 1224–1228

Yao M H, Liang Y M, Xia Y Q, et al. Bisimidazolium ionic liquids as the high-performance antiwear additives in poly(ethylene glycol) for steel-steel contacts. ACS Appl Mater Inter, 2009, 1(2): 467–471

Zhang H B, Xia Y Q, Yao M H, et al. The influences of methyl group at C2 position in imidazolium ring on tribological properties. Tribol Lett, 2009, 36(2): 105–111

Cai M R, Liang Y M, Yao M H, et al. Imidazolium ionic liquids as antiwear and antioxidant additive in poly(ethylene glycol) for steel/steel contacts. ACS Appl Mater Inter, 2010, 2(3): 870–876

Cai M R, Zhao Z, Liang Y M, et al. Alkyl imidazolium ionic liquids as friction reduction and anti-wear additive in polyurea grease for steel/steel contacts. Tribol Lett, 2010, 40(2): 215–224

Wornyoh E Y A, Jasti V K, Fred Higgs C. A review of dry particulate lubrication: Powder and granular materials. J Tribol, 2007, 129(2): 438–449

Zhou J F, Wu Z S, Zhang Z J, et al. Tribological behavior and lubricating mechanism of Cu nanoparticles in oil. Tribol Lett, 2000, 8(4): 213–218

Tarasov S, Kolubaev A, Belyaev S, et al. Study of friction reduction by nanocopper additives to motor oil. Wear, 2002, 252(1–2): 63–69

Zhao Y, Zhang Z, Dang H. Fabrication and tribological properties of Pb nanoparticles. J Nanopart Res, 2004, 6: 47–51

Yu H, Xu Y, Shi P, et al. Tribological properties and lubricating mechanisms of Cu nanoparticles in lubricant. T Nonferr Metal Soc, 2008, 18(3): 636–641

Zhang M, Wang X, Fu X, et al. Investigation of electrical contact resistance of ag nanoparticles as additives added to peg 300. Tribol T, 2009, 52(2): 157–164

Zhang M, Wang X, Liu W, et al. Performance and anti-wear mechanism of Cu nanoparticles as lubricating oil additives. Ind Lubr Tribol, 2009, 61(6): 311–318

Red’kin V E. Lubricants with ultradisperse diamond-graphite powder. Chem Tech Fuels oils, 2004, 40(3): 164–170

Yao Y, Wang X, Guo J, et al. Tribological property of onion-like fullerenes as lubricant additive. Mater Lett, 2008, 62(16): 2524–2527

Cumings J, Zettl A. Low-friction nanoscale linear bearing realized from multiwall carbon nanotubes. Science, 2000, 289: 602–604

Kis A, Jensen K, Aloni S. Interlayer forces and ultralow sliding friction in multiwalled carbon nanotubes. Phys Rev Lett, 2006, 97: 025501–4

Guo W L, Zhong W Y, Dai Y T, et al. Coupled defect-size effects on interlayer friction in multiwalled carbon nanotubes. Phys Rev Lett, 2005, 72: 075409–10

Liu L, Fang Z, Gu A, et al. Lubrication effect of the paraffin oil filled with functionalized multiwalled carbon nanotubes for bismaleimide resin. Tribol Lett, 2011, 42: 59–65

Guo Y F, Guo W L, Chen C F. Modifying atomic-scale friction between two graphene sheets: A molecular-force-field study. Phys Rev B, 2007, 76: 155429–5

Eswaraiah V, Sankaranarayanan V, Ramaprabhu S. Graphene-based engine oil nanofluids for tribological applications. ACS Appl Mater Interf, 2011, 3: 4221–4227

Zhang Z J, Zhang J, Xue Q J. Synthesis and characterization of a molybdenum disulfide nanocluster. J Phys Chem, 1994, 98(49): 12973–12977

Rapoport L, Lvovsky M, Lapsker I, et al. Friction and wear of bronze powder composites including fullerene-like WS2 nanoparticles. Wear, 2001 (1–2), 249: 149–156

Tenne R, Margulis L, Genut M, et al. Polyhedral and cylindrical structures of tungsten disulphide. Natrue, 1992, 360: 444–446

Golan Y, Drummond C, Homyonfer M, et al. Microtribology and direct force measurement of WS2 nested fullerene-like nanostructures. Adv Mater, 1999, 11(11): 934–937

Greenberg R, Halperin G, Etsion I, et al. The effect of WS2 nanoparticles on friction reduction in various lubrication regimes. Tribol Lett, 2004, 17(2): 179–186

Ye W, Cheng T, Ye Q, et al. Preparation and tribological properties of tetrafluorobenzoic acid-modified TiO2 nanoparticles as lubricant additives. Mater Sci Eng A, 2003, 359(1–2): 82–85

Zhang J Y, Yang S R, Xue Q J. Preparation and characterization of Ni(OH)2 nanoparticles coated with dialkyldithiophosphate. J Mater Res, 2000, 15(2): 541–545

Hernandezbattez A, Fernandezrico J, Navasarias A, et al. The tribological behaviour of ZnO nanoparticles as an additive to PAO. Wear, 2006, 261(3–4): 256–263

Hernandezbattez A, Gonzalez R, Viesca J, et al. Cuo, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear, 2008, 265(3–4): 422–428

Song H, Zhang Z. Study on the tribological behaviors of the phenolic composite coating filled with modified nano-TiO2. Tribol Int, 2008, 41(5): 396–403

Hu Z S, Dong J X. Study on antiwear and reducing friction additive of nanometer titanium borate. Wear, 1998, 216(1): 87–91

Xue Q J, Wang Q H. Wear mechanisms of polyetheretherketone composites filled with various kinds of SiC. Wear, 1997, 213(1-2): 54–58

Hu Z S, Dong J X, Chen G X, et al. Preparation and tribological properties of nanoparticle lanthanum borate. Wear, 2000, 243(1–2): 43–47

Hu Z S, Lai R, Lou F, et al. Preparation and tribological properties of nanometer magnesium borate as lubricating oil additive. Wear, 2002, 252(5–6): 370–374

Ji X, Chen Y, Zhao G, et al. Tribological properties of CaCO3 nanoparticles as an additive in lithium grease. Tribol Lett, 2010, 41(1): 113–119

Zhang M, Wang X, Fu X, et al. Performance and anti-wear mechanism of CaCO3 nanoparticles as a green additive in poly-alpha-olefin. Tribol Int, 2009, 42(7): 1029–1039

Gu C, Li Q, Gu Z, et al. Study on application of CeO2 and CaCO3 nanoparticles in lubricating oils. J Rare Earth, 2008, 26(2): 163–167

Lian Y F, Xue Q J, Zhang X H, et al. The mechanism of synergism between ZDDP and CeF3 additives. Lubr Sci, 1995, 7(261): 261–272

Zhou J F, Wu Z S, Zhang Z J, et al. Study on an antiwear and extreme pressure additive of surface coated LaF3 nanoparticles in liquid paraffin. Wear, 2001, 249(5–6): 333–337

Zhang Z F, Yu L G, Liu W M, et al. The effect of LaF3 nanocluster modified with succinimide on the lubricating performance of liquid paraffin for steel-on-steel system. Tribol Int, 2001, 34(2): 83–88

Wang L, Zhang M, Wang X, et al. The preparation of CeF3 nanocluster capped with oleic acid by extraction method and application to lithium grease. Mater Res Bull, 2008, 43(8-9): 2220–2227

Duan B. A study on colloidal PST-A new type of water-based lubrication additive. Wear, 1999, 236(1–2): 235–239

Duan B, Lei H. The effect of particle size on the lubricating properties of colloidal polystyrene used as water based lubrication additive. Wear, 2001, 249(5–6): 528–532

Chen W G, Gao Y Z, Zhang H C, et al. Self-repairing characteristics of superfine powder of hydroxyl magnesium silicate on a worn steel surface. J Chin Ceram Soc, 2010, 38: 762–767

National Lubricating Grease Institute (NLGI). Grease Production Survey Report For the Calendar Years 2009, 2007 and 2006. 2010, https://www.nlgi.org/

Li W, Kong X H, Ruan M, et al. Green waxes, adhesives and lubricants. Philos Transact A-Math Phys Eng Sci, 2010, 368(1929): 4869–4890

Haseeb A S M A, Fazal M A, Jahirul M I, et al. Compatibility of automotive materials in biodiesel: A review. Fuel, 2011, 90(3): 922–931

Sharma B K, Liu Z S, Adhvaryu A, et al. One-pot synthesis of chemically modified vegetable oils. J Agric Food Chem, 2008, 56: 3049–3056

Shahid E M, Jamal Y. A review of biodiesel as vehicular fuel. Renew Sust Energ Rev, 2008, 12(9): 2484–2494

Quinchia L A, Delgado M A, Franco J M, et al. Low-temperature flow behaviour of vegetable oil-based lubricants. Ind Crop Prod, 2012, 37(1): 383–388

Aluyor E O, Obahiagbon K O, Ori-jesu M. Biodegradation of vegetable oils: A review. Sci Res Essay, 2009, 4(6): 543–548

Erhan S Z, Sharma B K, Perez J M. Oxidation and low temperature stability of vegetable oil-based lubricants. Ind Crop Prod, 2006, 24(3): 292–299

Salimon J, Salih N, Yousif E. Biolubricants: Raw materials, chemical modifications and environmental benefits. Eur J Lipid Sci Tech, 2010, 112(5): 519–530

Arngek A, Vitintin J. Lubricating properties of rapeseed-based oils. J Synth Lubr, 1999, 16(4): 281–296

Ng J H, Ng H K, Gan S. Advances in biodiesel fuel for application in compression ignition engines. Clean Technol Envir, 2009, 12(5): 459–493

Regueira T, Lugo L, Fandiño O, et al. Compressibilities and viscosities of reference and vegetable oils for their use as hydraulic fluids and lubricants. Green Chem, 2011, 13(5): 1293–1302

Shashidhara Y M, Jayaram S R. Vegetable oils as a potential cutting fluid-An evolution. Tribol Int, 2010, 43(5-6): 1073–1081

Fox N, Stachowiak G. Vegetable oil-based lubricants-A review of oxidation. Tribol Int, 2007, 40(7): 1035–1046

Asadauskas S J, Grigucericiene A, Stoncius A. Review of late stages of oxidation in vegetable oil lubricant basestocks. Proceedings of the International Conference BALTTRIB, 2007

Salimon J, Salih N. Chemical modification of oleic acid oil for biolubricant industrial applications. Aust J Basic Appl Sci, 2010, 4: 1999–2003

Wang L, Wang T. Chemical modification of partially hydrogenated vegetable oil to improve its functional properties for candles. J Am Oil Chem Soc, 2007, 84(12): 1149–1159

Uosukainena E, Linkoa Y Y, Lämsäb M, et al. Transesterification of trimethylolpropane and rapeseed oil methyl ester to environmentally acceptable lubricants. JAOCS, 1998, 75(11): 1557–1563

Salimon J, Salih N. Improved low temperature properties of 2-ethylhexyl 9 (10)-hydroxy-10 (9)-acyloxystearate derivatives Eur J Sci Res, 2009, 31(4): 583–591

Schmidt M A, Dietrich C R, Cahoon E B. Biotechnological enhancement of soybean oil for lubricant applications. Biotechnological Enhancement of Soybean Oil for Lubricant Applications Taylor & Francis Group, LLC, 2006

Kralova I, Sjöblom J. Biofuels-renewable energy sources: A review. J Disper Sci Technol, 2010, 31(3): 409–425

Moser B R. Biodiesel production, properties, and feedstocks. In Vitro Cell Dev Biol-Plant, 2009, 45(3): 229–266

Yusuf N N A N, Kamarudin S K, Yaakub Z. Overview on the current trends in biodiesel production. Energ Convers Manage, 2011, 52(7): 2741–2751

Dresel W H. Biologically degradable lubricating greases based on industrial crops. Ind Crop Prod, 1994, 2(4): 281–288

Adhvaryu A, Sung C, Erhan S Z. Fatty acids and antioxidant effects on grease microstructures. Ind Crop Prod, 2005, 21(3): 285–291

Sánchez R, Franco J M, Delgado M A, et al. Development of new green lubricating grease formulations based on cellulosic derivatives and castor oil. Green Chem, 2009, 11(5): 686–693

Wang X L, Kato K, Adachi K, et al. The effect of laser texturing of sic surface on the critical load for the transition of water lubrication mode from hydrodynamic to mixed. Tribol Int, 2001, 34(10): 703–711

Etsion I. State of the art in laser surface texturing. J Tribol, 2005, 127(1): 248–253

Etsion I. Improving tribological performance of mechanical components by laser surface texturing. Tribol Lett, 2004, 17(4): 733–737

Yamakiri H, Sasaki S, Kurita T, et al. Effects of laser surface texturing on friction behavior of silicon nitride under lubrication with water. Tribol Int, 2011, 44(5): 579–584

Garrido A H, González R, Cadenas M, et al. Tribological behavior of laser-textured nicrbsi coatings. Wear, 2011, 271(5–6): 925–933

Vilhena L M, Podgornik B, Vižintin J, et al. Influence of texturing parameters and contact conditions on tribological behaviour of laser textured surfaces. Meccanica, 2010, 46(3): 567–575

Yuan S, Huang W, Wang X. Orientation effects of micro-grooves on sliding surfaces. Tribol Int, 2011, 44(9): 1047–1054

Myshkin N K, Grigoriev A Y. Morphology: Texture, shape, and color of friction surfaces and wear debris in tribodiagnostics problems. J Frict Wear, 2008, 29(3): 192–199

Erdemir A. Review of engineered tribological interfaces for improved boundary lubrication. Tribol Int, 2005, 38(3): 249–256

Wang X L, Kato K, Adachi K, et al. Loads carrying capacity map for the surface texture design of sic thrust bearing sliding in water. Tribol Int, 2003, 36(3): 189–197

Ryk G, Kligerman Y, Etsion I. Experimental investigation of laser surface texturing for reciprocating automotive components. Tribol Trans, 2002, 45(4): 444–449

Ronen A, Etsion I, Kligerman Y. Friction-reducing surface texturing in reciprocating automotive components. Tribol Trans, 2001, 44(3): 359–366

Pettersson U. Influence of surface texture on boundary lubricated sliding contacts. Tribol Int, 2003, 36(11): 857–864

Yu X Q, He S, Cai R L. Frictional characteristics of mechanical seals with a laser-textured seal face. J Mater Process Tech, 2002, 129(1–3): 463–466

Pettersson U, Jacobson S. Textured surfaces for improved lubrication at high pressure and low sliding speed of roller/piston in hydraulic motors. Tribol Int, 2007, 40(2): 355–359

Raeymaekers B, Etsion I, Talke F E. Enhancing tribological performance of the magnetic tape/guide interface by laser surface texturing. Tribol Lett, 2007, 27(1): 89–95

Borghi A, Gualtieri E, Marchetto D, et al. Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear, 2008, 265(7-8): 1046–1051

Kango S, Singh D, Sharma R K. Numerical investigation on the influence of surface texture on the performance of hydrodynamic journal bearing. Meccanica, 2011, 47(2): 469–482

Mang T, Dresel W. Lubricants and Lubrication. 2nd ed. Darmstadt: Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, 2007

Nosonovsky M. Self-organization at the frictional interface for green tribology. Philos Transact A-Math Phys Eng Sci, 2010, 368(1929): 4755–4774

Lee S M. International Encyclopedia of Composites. New York: VCH Publishers, 1990

Rohatgi P J B P K, Yust C S. Tribology of Composite Materials. ASM International, Materials Park, 1990: 101

Sung N P S N H. Effect of fiber orientation on friction and wear of fiber reinforced polymeric composites. Wear, 1979, 53(1): 129–141

Khedkar I N J, Meletis E I. Sliding wear behavior of PTFE composites. Wear, 2002, 252(5–6): 361–369

Blanchet F E K T A. Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear, 1992, 153(1): 229–243

Li F, Yan F Y, Yu L G, et al. The tribological behaviors of coppercoated graphite filled PTFE composites. Wear, 2000, 237(1): 33–38

Wang Q H, Xue Q J, Shen W C. The friction and wear properties of nanometre SiO2 filled polyetheretherketone. Tribol Int, 1997, 30(3): 193–197

Wang Q H, Xue Q J, Shen W C, et al. The friction and wear properties of nanometer ZrO2-filled polyetheretherketone. J Appl Polym Sci, 1998, 69(1):135–141

He J, Wang L, Li W, et al. Experimental observations on the mechanical properties of nanoscale ceramic/teflon multilayers. Mate Chem Phys, 1998, 54(1–3): 334–337

Vande Voort S B J. The growth and bonding of transfer film and the role of CuS and PTFE in the tribological behavior of peek. Wear, 1995, 181-183: 212–221

Ben T, Chen C H, Cao H, et al. LB film structure of nanometer-scale PEEKK macrocyclic oligomers. Macromol Rapid Commun, 2002, 23: 196–199

Mondelin A, Furet B, Rech J. Characterisation of friction properties between a laminated carbon fibres reinforced polymer and a monocrystalline diamond under dry or lubricated conditions. Tribol Int, 2010, 43(9): 1665–1673

Dhieb H, Buijnsters J G, Celis J P, et al. Degradation of carbon fiber reinforced epoxy composites under sliding in ambient air. Sustain Constr Design, 2011: 53–58

Theiler G, Hubner W, Gradt T, et al. Friction and wear of carbon fibre filled polymer composites at room and low temperatures. Matwiss. u. Werkstofftechnik, 2004, 35(10-11): 683–689

Shi Y. The effect of surface modification on the friction and wear behavior of carbon nanofiber-filled PTFE composites. Wear, 2008, 264(11-12): 934–939

Jia J, Chen J, Zhou H, et al. Comparative investigation on the wear and transfer behaviors of carbon fiber reinforced polymer composites under dry sliding and water lubrication. Compos Sci Technol, 2005, 65(7–8): 1139–1147

Sun L, Yang Z, Li X. Tensile and tribological properties of ptfe and nanoparticles modified epoxy-based polyester fabric composites. Mater Sci Eng A, 2008, 497(1–2): 487–494

Bijwe J, Rattan R, Fahim M. Abrasive wear performance of carbon fabric reinforced polyetherimide composites: Influence of content and orientation of fabric. Tribol Int, 2007, 40(5): 844–854

Wan Y, Chen G, Raman S, et al. Friction and wear behavior of three-dimensional braided carbon fiber/epoxy composites under dry sliding conditions. Wear, 2006, 260(9–10): 933–941

Su F, Zhang Z, Wang K, et al. Friction and wear properties of carbon fabric composites filled with nano-Al2O3 and nano-Si3N4. Composites Part A, 2006, 37(9): 1351–1357

Su F, Zhang Z, Guo F, et al. Effects of solid lubricants on friction and wear properties of nomex fabric composites. Mater Sci Eng A, 2006, 424(1–2): 333–339

Su F, Zhang Z, Guo F, et al. Tribological properties of the composites made of pure and plasma treated-nomex fabrics. Wear, 2006, 261(3–4): 293–300

Zhang Z, Su F, Wang K, et al. Study on the friction and wear properties of carbon fabric composites reinforced with micro- and nanoparticles. Mater Sci Eng A, 2005, 404(1–2): 251–258

Zhang X, Pei X, Wang Q. Friction and wear studies of polyimide composites filled with short carbon fibers and graphite and micro SiO2. Mater Design, 2009, 30(10): 4414–4420

Wang Q, Zhang X, Pei X. Study on the friction and wear behavior of basalt fabric composites filled with graphite and nano-SiO2. Mater Design, 2010, 31(3): 1403–1409

Sang K. A study of the SiC-L composite ceramics for self-lubrication. Wear, 2002, 253(11–12): 1188–1193

Carrapichano J M, Gomes J R, Silva R F. Tribological behaviour of Si3N4-BN ceramic materials for dry sliding applications. Wear, 2002, 253: 1070–1076

Bewilogua K, Bräuer G, Dietz A, et al. Surface technology for automotive engineering. CIRP Annals-Manuf Technol, 2009, 58(2): 608–627

Donnet C, Erdemirb A. Historical developments and new trends in tribological and solid lubricant coatings. Surf Coat Technol, 2004, 180–181: 76–84

Wolf Dieter M. Titanium aluminum nitride films: A new alternative to tin coatings. J Vac Sci Technol, 1986, A4(6): 2717–2725

PalDey S C D S. Single layer and multilayer wear resistant coatings of (Ti, Al)N: A review. Mater Sci Eng A, 2003, 342: 58–79

Veprek S, Reiprich S, Shizhi L. Superhard nanocrystalline composite materials: The TiN/Si3N4 system. Appl Phys Lett, 1995, 66(20): 2640

Yuan Z G, Yang J F, Wang X, et al. Characterization and properties of quaternary Mo-Si-C-N coatings synthesized by magnetron sputtering technique. Surf Coat Technol, 2011, 205(10): 3307–3312

Polcar T, Cavaleiro A. High temperature properties of CrAlN, CrAlSiN and AlCrSiN coatings-structure and oxidation. Mater Chem Phys, 2011, 129(1–2): 195–201

Polcar T, Cavaleiro A. Structure and tribological properties of alcrtin coatings at elevated temperature. Surf Coat Technol, 2011, 205: S107–S110

Hong Y S, Kwon S H, Wang T, et al. Effects of Cr interlayer on mechanical and tribological properties of Cr-Al-Si-N nanocomposite coating. T Nonferr Metal Soc, 2011, 21: s62–s67

Lin J, Moore J J, Moerbe W C, et al. Structure and properties of selected (Cr-Al-N, TiC-C, Cr-B-N) nanostructured tribological coatings. Int J Refractory Metals Hard Mater, 2010, 28: 2–14

Lin C, Duh J. Corrosion behavior of (Ti-Al-Cr-Si-V)xNy coatings on mild steels derived from RF Magnetron sputtering. Surf Coat Technol, 2008, 203(5-7): 558–561

Ma S L, Ma D Y, Guo Y, et al. Synthesis and characterization of super hard, self-lubricating Ti-Si-C-N nanocomposite coatings. Acta Mater, 2007, 55(18): 6350–6355

Capek J, Hreben S, Zeman P, et al. Effect of the gas mixture composition on high-temperature behavior of magnetron sputtered Si-BZC-N coatings. Surf Coat Technol, 2008, 203(5–7): 466–469

Paternoster C, Fabrizi A, Cecchini R, et al. Thermal evolution and mechanical properties of hard Ti-Cr-B-N and Ti-Al-Si-B-N coatings. Surf Coat Technol, 2008, 203(5–7): 736–740

Krzanowski J E. Fabrication and tribological properties of composite coatings produced by lithographic and microbeading methods. Surf Coat Technol, 2009, 204(6–7): 955–961

Panjan M, Sturm S, Panjan P, et al. The influence of rotation during sputtering on the stoichiometry of TiAlN/CrNx multilayer coating. Surf Coat Technol, 2008, 203(5-7): 554–557

Luo Q S, Wang S C, Zhou Z Z, et al. Structure characterization and tribological study of magnetron sputtered nanocomposite nc-TiAlV (N,C)/a-C coatings. J Mater Chem, 2011, 21: 9746–9756

Zhu M, Li M S, Xu J J, et al. Short-term oxidation and hot corrosion resistance of a gradient CrN/Cr1−x AlxN coating. Mater Corros, 2010, 61(11): 939–946

Savisalo T, Lewis D, Hovsepian P. Microstructure and properties of novel wear and corrosion resistant CrON/NbON nano-scale multilayer coatings. Surf Coat Technol, 2006, 200(8): 2731–2737

Hovsepian P E, Munz W D. Recent progress in large-scale production of nanoscale multilayer/superlattice hard coatings. Vacuum, 2003, 69: 27–36

Erdemir A, Donnet C. Tribology of diamond-like carbon films: Recent progress and future prospects. J Phys D-Appl Phys, 2006, 39(18): R311–R327

Kalin M, Velkavrh I, Vižintin J, et al. Review of boundary lubrication mechanisms of DLC coatings used in mechanical applications. Meccanica, 2008, 43(6): 623–637

Hainsworth S V, Uhure N J. Diamond like carbon coatings for tribology: Production techniques, characterisation methods and applications. Int Mater Rev, 2007, 52(3): 153–174

Kano M, Tanimoto I. Wear mechanism of high wear-resistant materials or automotive valve trains. Wear, 1991, 151(2): 229–243

Dai M J, Zhou K S, Yuan Z H, et al. The cutting performance of diamond and DLC-coated cutting tools. Diamond Relat Mater, 2000, 9(9–10): 1753–1757

Jiang J. Structure and mechanics of W-DLC coated spur gears. Surf Coat Technol, 2003, 176(1): 50–56

Tung S. Tribological characteristics and surface interaction between piston ring coatings and a blend of energy-conserving oils and ethanol fuels. Wear, 2003, 255(7–12): 1276–1285

Hershberger J. Evaluation of DLC coatings for spark-ignited, directinjected fuel systems. Surf Coat Technol, 2004, 179(2–3): 237–244

Kalin M, Vizintin J. The tribological performance of dlc-coated gears lubricated with biodegradable oil in various pinion/gear material combinations. Wear, 2005, 259(7–12): 1270–1280

Etsion I, Halperin G, Becker E. The effect of various surface treatments on piston pin scuffing resistance. Wear, 2006, 261(7–8): 785–791

Kano M. DLC coating technology applied to sliding parts of automotive engine. New Diamond Frontier Carbon Technol, 2006, 16: 201–210

Vanhulsel A, Velasco F, Jacobs R, et al. DLC solid lubricant coatings on ball bearings for space applications. Tribol Int, 2007, 40(7): 1186–1194

Lawes S D A, Hainsworth S V, Fitzpatrick M E. Impact wear testing of diamond-like carbon films for engine valve-tappet surfaces. Wear, 2010, 268(11–12): 1303–1308

Igor V, Mitjan K, Jozef V. The performance and mechanisms of DLC coated surfaces in contact with steel in boundary-lubrication conditions-A review. J Mech Eng, 2008, 54: 189–206

Ronkainen H, Varjus S, Koskinen J, et al. Differentiating the tribological performance of hydrogenated and hydrogen-free DLC coatings. Wear, 2001, 249(3–4): 260–266

Dimigen H, Hübsch H, Memming R. Tribological and electrical properties of metal-containing hydrogenated carbon films. Appl Phys Lett, 1987, 50(16): 1056–1058

Chen J S, Lau S P, Sun Z, et al. Metal-containing amorphous carbon films for hydrophobic application. Thin Solid Films, 2001, 398–399: 110–115

Rubio-Roy M, Corbella C, Andújar J L, et al. Tribological properties of fluorinated amorphous carbon thin films New Tribological Ways 2011, ISBN: 978-953-307-206-7, InTech, Available from: http://www.intechopen.com/articles/show/title/tribological-properties-of-fluorinated-amorphous-carbon-thin-films(47-70)

Vercammen K. Tribological behaviour of DLC coatings in combination with biodegradable lubricants. Tribol Int, 2004, 37(11–12): 983–989

Yang S H, Kong H, Lee K R, et al. Effect of environment on the tribological behavior of Si-incorporated diamond-like carbon films. Wear, 2002, 252(1–2): 70–79

Choi J, Nakao S, Miyagawa S, et al. The effects of Si incorporation on the thermal and tribological properties of DLC films deposited by PBII&D with bipolar pulses. Surf Coat Technol, 2007, 201(19–20): 8357–8361

Zou Y S, Wu Y F, Huang R F, et al. Mechanical properties and thermal stability of nitrogen incorporated diamond-like carbon films. Vacuum, 2009, 83(11): 1406–1410

Voevodin A A, O’Neill J P, Zabinski J S. Tribological performance and tribochemistry of nanocrystalline WC/amorphous diamond-like carbon composites. Thin Solid Films, 1999, 342(1–2): 194–200

Yu X, Hua M, Wang C. Influence of Ag content and nanograin size on microstructure, mechanical and sliding tribological behaviors of Ag-DLC films. J Nanosci Nanotechnol, 2009, 9: 6366–6371

Yu X, Wang C, Hua M, et al. Influence of Cr contents and nanograin sizes on microstructure, mechanical and sliding tribological behaviors of hard Cr-diamond-like carbon films. J Nanosci Nanotechnol, 2010, 10: 5379–5382

Cselle T. Application of coatings for tooling quo vadis 2005? Vakuum in Forschung Und Praxis VIP, 2005, 17(S1): 33–39

Veprek S, Veprekheijman M, Karvankova P, et al. Different approaches to superhard coatings and nanocomposites. Thin Solid Films, 2005, 476(1): 1–29

Veprek S, Veprekheijman M. Industrial applications of superhard nanocomposite coatings. Surf Coat Technol, 2008, 202(21): 5063–5073

Voevodin A A, Zabinski J S. Supertough wear-resistant coatings with “chameleon” surface adaptation. Thin Solid Films, 2000, 370: 223–231

Lin D Y, Zhao Y T. Preparation of novel hydroxyapatite/Yttria-stabilized-Zirconia gradient coatings by magnetron sputtering. Adv Eng Mater, 2011, 13(1-2): B18–B24

Zhang J, Lv H, Cui G, et al. Effects of bias voltage on the microstructure and mechanical properties of (Ti, Al, Cr)N hard films with N-gradient distributions. Thin Solid Films, 2011, 519(15): 4818–4823

Louro C, Moura C W, Carvalho N, et al. Thermal stability in oxidative and protective environments of a-C:H cap layer on a functional gradient coating. Diamond Relat Mater, 2011, 20(2): 57–63

Wang L, Wan S, Wang S C, et al. Gradient DLC-based nanocomposite coatings as a solution to improve tribological performance of aluminum alloy. Tribol Lett, 2010, 38(2): 155–160

Zabinski S, Donley M S, Dyhouse V J, et al. Chemical and tribological characterization of PbO-MnO2 films grown by pulsed laser deposition. Thin Solid Films, 1992, 214: 156–163

Zabinski J S, Donley M S, McDevitt N T. Mechanistic study of the synergism between Sb2O3 and MoS2 lubricant systems using Raman spectroscopy. Wear, 1993, 165(1): 103–108

Wang Y, Wang L, Wang S C, et al. Nanocomposite microstructure and environment self-adapted tribological properties of highly hard graphite-like film. Tribol Lett, 2010, 40(3): 301–310

Donnet C. Historical developments and new trends in tribological and solid lubricant coatings. Surf Coat Technol, 2004, 180–181: 76–84

Carre D. The use of solid ceramic and ceramic hard-coated components to prolong the performance of perfluoropolyalkylether lubricants. Surf Coat Technol, 1990, 43–44: 609–617

Xia Y, Zhou F, Sasaki S, et al. Remarkable friction stabilization of AISI 52100 steel by plasma nitriding under lubrication of alkyl naphthalene. Wear, 2010, 268(7–8): 917–923

Kano M. Super low friction of dlc applied to engine cam follower lubricated with ester-containing oil. Tribol Int, 2006, 39(12): 1682–1685

Leschziner M A, Choi H, ChoiPhil K S. Flow-control approaches to drag reduction in aerodynamics: Progress and prospects. Phil Trans R Soc A, 2011, 369: 1349–1351

Mavros P, Ricard A, Xuereb C, et al. A study of the effect of dragreducing surfactants on flow patterns in stirred vessels. Chem Eng Res Des, 2011, 89(1): 94–106

Dean B, Bhushan B. Shark-skin surfaces for fluid-drag reduction in turbulent flow: A review. Phil Trans R Soc A, 2010, 368: 4775–4806

Voronov R S, Papavassiliou D V, Lee L L. Boundary slip and wetting properties of interfaces: Correlation of the contact angle with the slip length. J Chem Phys, 2007, 124(20): 204701–10

Sbragaglia M, Prosperetti A. A note on the effective slip properties for microchannel flows with ultrahydrophobic surfaces. Phys Fluids, 2007, 19(4): 043603–8

Sahraoui M, Kaviany M. Slip and no-slip temperature boundary conditions at interface of porous, plain media: Conduction. Int J Heat Mass Transfer, 1993, 36: 1019–1033

Herr A E, Molho J I, Santiago J G, et al. Electroosmotic capillary flow with nonuniform Zeta potential. Anal Chem, 2000, 72(5): 1053–1057

Pismen L M, Rubinstein B Y. Kinetic slip condition, van der waals forces, and dynamic contact angle. Langmuir, 2001, 17: 5265–5270

Sparreboom W, van den Berg A, Eijkel J C T. Principles and applications of nanofluidic transport. Nature Nanotech, 2009, 4: 713–720

Chakraborty S. Microfluidics and Microfabrication. Berlin: Springer Science+Business Media, LLC, 2010

Wu W C, Wang X L, Wang D A, et al. Alumina nanowire forests via unconventional anodization and super-repellency plus low adhesion to diverse liquids. Chem Comm, 2009, 9: 1043–1045

Forsberg P, Nikolajeff F, Karlsson M. Cassie-Wenzel and Wenzel-Cassie transitions on immersed superhydrophobic surfaces under hydrostatic pressure. Soft Matter, 2011, 7: 104–109

Ou J, Perot J B, Rothstein J P. Laminar drag reduction in microchannels using ultrahydrophobic surfaces. Phys Fluids, 2004, 16: 4635–4643

Choi C H, Kim C J. Large slip of aqueous liquid flow over a nanoengineered superhydrophobic surface. Phys Rev Lett, 2006, 96: 066001–4

Zhou M, Li J, Wu C X, et al. Fluid drag reduction on superhydrophobic surfaces coated with carbon nanotube forests (CNTs). Soft Matter, 2011, 7: 4391–4396

Truesdell R, Mammoli A, Vorobieff P, et al. Drag reduction on a patterned superhydrophobic surface. Phys Rev Lett, 2006, 97: 044504–4

Watanabe K, Udagawa Y, Udagawa H. Drag reduction of Newtonian fluid in a circular pipe with a highly water-repellent wall. J Fluid Mech, 1999, 381, 225–238

Daniello R J, Waterhouse N E, Rothstein J P. Drag reduction in turbulent flows over superhydrophobic surface. Phys Fluids, 2009, 21: 085103–9

Chen J H, Tsai C C, Kehr Y Z, et al. An experimental study of drag reduction in a pipe with superhydrophobic coating at moderate reynolds numbers. EPJ Web of Conferences, 2010, 6: 19005

Bechert D W, Bruse M, Hage W, et al. Experiments on drag-reducing surfaces and their optimization with an adjustable geometry. J Fluid Mech, 1997, 338: 59–87

Walsh M J, Anders J B Jr. Riblet/LEBU research at NASA Langley. Appl Sci Res, 1989, 46: 255–262

Bechert D W, Bruse M, Hage W, et al. Biological surfaces and their technological application-Laboratory and flight experiments on drag reduction and separation control. InAIAA 28th Fluid Dynamics Conference. Snowmass Village, 1997, paper No. AIAA-1997-1960

Weiss M H. Implementation of drag reduction techniques in natural gas pipelines. In 10th European Drag Reduction Working Meeting, Berlin, Germany, 1997. 19–21

Matthews J N A. Low-drag suit propels swimmers. Phys Today, 2008, 61(8): 32

Kramer M O. Boundary layer stabilisation by distributed damping. J Aero Sci, 1957, 24: 459–460

Kramer M O. Boundary layer stabilisation by distributed damping. J Am Soc NavEngr, 1960, 72: 25–33

Benjamin T B. Fluid flow with flexible boundaries. In Proc. 11th Int. Cong. on Applicationof Mathematics. Gortler H, ed. Berlin: Springer, 1964: 109–128

Semenov B N. On conditions of modelling and choice of viscoelastic coatings for drag reduction. In: Recent Developments in turbulence management. Choi K S, ed. Dordrecht: Kluwer. 1991, 241-262

Choi K S, Yang X, Clayton B R, et al. Turbulent drag reduction using compliant surfaces. Proc R Soc Lond A, 1997, 453: 2229–2240

Kulik V M, Poguda I S, Semenov B N. Experimental investigation of one-layer viscoelastic coatings action on turbulent friction and wall pressure pulsations. In: Recent Developments in Turbulence Management. Choi K S, ed. Dordrecht: Kluwer, 1991. 263–289

Carpenter P W. Optimization of multiple-panel compliant walls for delay of laminar-turbulent transition. AIAA J, 1993, 31: 1187–1188

Gad-el-Hak M. Compliant coatings for drag reduction. Prog Aerosp Sci, 2002, 38(1): 77–99

Semenov B N, Amirov A I, Kulik V M, et al. Experimental studies of compliant coatings for reduction of turbulent friction. Thermophys Aeromech, 2007, 14(1): 133–142

Lee I W, Chun H H. Design parameter optimization of compliant coating for drag reduction. International Conference on Ship Drag Reduction (SMOOTH-SHIPS), Istanbul, Turkey, 20–21 May, 2010

McCormick M E, Bhattacharya R. Drag reduction of a submersible hull by electrolysis. Nav Eng J, 1973, 85(2): 11–16

Pang M J, Wei J J, Yu B. Numerical studies on effects of bubbles regular array on the liquid-phase turbulence. Can J Chem Eng, 2010, 88(6): 945–958

Madavan N K, Deutsch S, Merkle C L. Reduction of turbulent skin friction by micro-bubbles. Phys Fluids, 1984, 27: 356–363

Kato H, Iwashina T, Miyanaga M, et al. Effect of microbubbles on the structure of turbulence in a turbulent boundary layer. J Marine Sci Technol, 1999, 4: 155–162

Tsai J F, Chen C C. Experimental study on the micro-bubble drag reduction effect in water tunnel and towing tank. The 13th Asia-Pacific Workshop on Marine Hydrodynamics, Shanghai, China, 2006

Vakarelski I U, Marston J O, Chan D Y C, et al. Drag reduction by Leidenfrost vapor layers. Phys Rev Lett, 2011, 106: 214501–4

Latorre R. Ship hull drag reduction using bottom air injection. Ocean Eng, 1997, 24: 161–175

Sanders W C, Winkel E S, Dowling D R, et al. Bubble friction drag reduction in a high-Reynolds-number flat-plate turbulent boundary layer. J Fluid Mech, 2006, 552: 353–380

Elbing B R, Winkel E S, Lay K A, et al. Bubble-induced skin-friction drag reduction and the abrupt transition to air-layer drag reduction. J Fluid Mech, 2008, 612: 201–236

Ceccio S L. Friction drag reduction of external flows with bubble and gas injection. Annu Rev Fluid Mech, 2010, 42: 183–203

Toms B A. Some observation on the flow of linear polymer solutions through straight tubes at large Reynolds number. In: Proceedings of the 1st International Congress on Rheology, North-Holland Amsterdam, 1948, Vol. 2. 135–141

Lumley J L. Drag reduction in turbulent flow by polymer additives. J Polym Sci Macromol Rev, 1973, 7(1): 263–190

L’vov V S, Pomyalov A, ProcacciaI I, et al. Drag reduction by polymers in wall bounded turbulence. Phys Rev Lett, 2004, 92: 244503–4

Joseph D D. Fluid Dynamics of Viscoelastic Liquids. New York: Springer Verlag, 1990

Al-Sarkhi A, Abu-Nada E. Effect of drag reducing polymer onannular flow patterns of air and water in a small horizontal pipeline. In: Twelfth International Conference on Multiphase Production Technology, 25–27 May 2005, Barcelona, Spain

Al-Wahaibi T, Smith M, Angeli P. Effect of drag-reducing polymers on horizontal oil-water flows. J Petrol Sci Eng, 2007, 57: 334–346

Al-Yaari M, Soleimani A, Abu-Sharkh B, et al. Effect of drag reducing polymers on oil-water flow in a horizontal pipe. Int J Multiphase flow, 2009, 35: 516–524

Kulicke W M, Kotter M, Gragem H. Drag Reduction Phenomenon With Special Emphasis On Homogenous Polymer Solutions: Polymer Characterization/Polymer Solutions. Berlin: Springer-Verlag, 1989

Counc N S. Submarine platform technology. In: Technology for the United States Navy and Marine Corps, 2000–2035: Becoming a 21st-Century Force. Vol. 6, Platforms. Washington, DC: Natl Acad Press, 1997. 85–114

Winkel E S, Oweis G F, Vanapalli S A, et al. Friction drag reduction at high reynolds numbers using injected polymer solutions. 26th ONR Symp. Naval Hydrodynamics, Rome

Winkel E S, Oweis G F, Vanapalli S A, et al. High-Reynolds-number turbulent boundary layer friction drag reduction from wall-injected polymer solutions. J Fluid Mech, 2009, 621: 259–288

Stenzel V, Wilke Y, Hage W. Drag-reducing paints for the reduction of fuel consumption in aviation and shipping. Prog Org Chem, 2011, 70: 224–229

Sabadini E, Francisco K R, Bouteiller L. Bis-urea-based supramolecular polymer: The first self-assembled drag reducer for hydrocarbon solvents. Langmuir, 2010, 26(3): 1482–1486

Watanabe K. In: Proceedings of the International Symposium on Seawater Drag Reduction. Newport Rhode Island, July 1998

Semenov B N. The combination of polymer, compliant wall, and microbubble drag reduction schemes. Adv Mech Eng, 2011, Article ID 743975, doi:10.1155/2011/743975

Liu Y H, Xiao Y Q, Luo J B. Preparation of poly (N-isopropylacrylamide) brush bonded on silicon substrate and its water-based lubricating property. Sci China Tech Sci, 2012, 55: 2656–2661

Guo Y B, Wang D G, Liu S H, et al. Shear of molecular deposition films on glass substrates determined by tribometer. Sci China Tech Sci, 2011, 54: 1005–1010

Liu Y H, Wang X K, Liu P X, et al. Modification on the tribological properties of ceramics lubricated by water using fullerenol as a lubricating additive. Sci China Techn Sci, 2012, 55: 2656–2661

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, M., Guo, R., Zhou, F. et al. Lubricating a bright future: Lubrication contribution to energy saving and low carbon emission. Sci. China Technol. Sci. 56, 2888–2913 (2013). https://doi.org/10.1007/s11431-013-5403-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-013-5403-2