Abstract

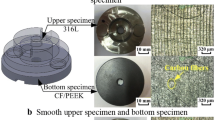

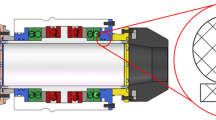

Elastic rubbers are widely used in nature and engineering. In order to better understand soft rough contact under dry and wet conditions during deepwater pipelaying process, various polyurethane (PU) discs both in PU-pipe and PU-steel sliding combinations have been investigated by using self-developed tribometer. The tribological test results show that the friction coefficient can be clearly seen: PU90< PU80 < PU70, under dry conditions. Experimental results also indicate that the two dramatic increases of the frictional coefficient exist in the rough soft PU-pipe contact. The potential influence of asperities and thin liquid film is discussed.

Similar content being viewed by others

References

Clauss G F, Weede H, Riekert T. Offshore pipe laying operations interaction of vessel motions and pipeline dynamic stresses. Appl Ocean Res, 1992, 14: 175–90

Guarracino F, Mallardo V. A refined analytical analysis of submerged pipelines in seabed laying. Appl Ocean Res, 1999, 21(1): 281–293

Lenci S, Callegari M. Simple analytical models for the J-lay problem. Acta Mech, 2005, 178(1–2): 23–39

Lawinscky da Silva D M, Lima Jr. M H, Jacob B P. Simulation of the pipeline-laybarge interaction in pipelaying procedures. Int J Model Simul Petrol Indus, 2009, 3: 13–22

Giuliana M, Stefano M, Paolo S G. A tensioner simulator for use in a pipelaying design tool. Mechatronics, 2009, 19: 1280–1285

Wang W M, Wang L Q, Wang C D. A novel deepwater structures pose measurement method and experimental study. Measurement, 2012, 45(5): 1151–1158

Wang W M, Wang L Q, Wang C D. Deep-sea structure pose measurement’s error analysis and experiment study. Ocean Eng, 2013, 70: 141–148

Han F. Design theory and experimental study of J-lay tower used for deepwater pipelaying (in Chinese). Doctoral Dissertation. Beijing: China University of Petroleum-Beijing, 2012

Pan X D. Wet sliding friction of elastomer compounds on a rough surface. Wear, 2007, 262: 707–717

Jin Z M, Dowson D. Bio-friction. Friction, 2013, 2: 100–113

Markus A, Birken L, Sellenschloh K, et al. Damage due to rolling in total knee replacement—The influence of tractive force. Friction, 2013, 2: 178–185

Sheng G, Lee J H, Narravula V, et al. Experimental characterization and analysis of wet belt friction and the vibro-acoustic behavior. Tribol Int, 2011, 44: 258–265

Tan G B, Liu S H, Wang D G, et al. In situ observation of wax-in-oil flow in rough soft contact. Tribol Lett, 2013, 52: 93–103

Vicente J, Spikes H A, Stokes J R. Viscosity ratio effect in the emulsion lubrication of soft EHL contact. J Tribol, 2006, 128(4): 795–800

Vicente J, Stokes J R, Spikes H A. Soft lubrication of model hydrocolloids. Food Hydrocolloids, 2006, 20(4): 483–491

Bongaerts J H H, Fourtouni K, Stokes J R. Soft-tribology: Lubrication in a compliant PDMS-PDMS contact. Tribol Int, 2007, 40(10–12): 1531–1542

Myant C, Spikes H A, Stokes J R. Influence of load and elastic properties on the rolling and sliding friction of lubricated compliant contacts. Tribol Int, 2010, 43(1–2): 55–63

Myant C, Reddyhoff T, Spikes H A. Laser-induced fluorescence for film thickness mapping in pure sliding lubricated, compliant, contacts. Tribol Int, 2010, 43(11): 1960–1969

Andablo-Reyes E, Vicente J, Hidalgo-Álvarez R, et al. Soft-Elasto-Ferrohydrodynamic Lubrication. Tribol Lett, 2010, 39: 109–114

Bombard A J F, Vicente J. Thin-film rheology and tribology of magnetorheological fluids in isoviscous-EHL contacts. Tribol Lett, 2012, 47: 149–162

Wang J Z, Yan F Y, Xue Q J. Tribological behavior of PTFE sliding against steel in sea water. Wear, 2009, 267(9–10): 1634–1641

Wang J Z, Yan F Y, Xue Q J. Friction and wear behavior of ultra-high molecular weight polyethylene sliding against GCr15 steel and electroless Ni-P alloy coating under the lubrication of seawater. Tribol Lett, 2009, 35: 85–95

Wang J Z, Yan F Y, Xue Q J. Tribological behaviors of some polymeric materials in sea water. Chin Sci Bull, 2009, 54(24): 4541–4548

Chen B B, Wang J Z, Yan F Y. Friction and wear behaviors of several polymers sliding against GCr15 and 316 steel under the lubrication of sea water. Tribol Lett, 2011, 42: 17–25

Xue Q J, Wang L P. Diamond-like Carbon Film (in Chinese). Beijing: Science Press, 2012

Wang L P, Guan X Y, Zhang G A. Friction and wear behaviors of carbon-based multilayer coatings sliding against different rubbers in water environment. Tribol Int, 2013, 64: 69–77

Zhang S W. Tribology of Elastomers. Amsterdam: Elsevier, 2004

Zhang S W, Yang Z C. Energy theory of rubber abrasion by a line contact. Tribol Int, 1997, 30(12): 839–843

Tan G B, Liu S H, Wang D G, et al. Tribological behavior of a line contact between rubber and wax (application to the wax-removal of oil pipeline pigging). Proceedings of World Tribology Congress, Torino, Italy, 2013

Zhang S W, He R Y, Wang D G, et al. Abrasive erosion of polyure thane. J Mater Sci, 2001, 36: 5037–5043

Zhang S W, Liu H C, He R Y. Mechanisms of wear of steel by natural rubber in water medium. Wear, 2004, 256: 226–232

Peressadko A G, Hosoda N, Persson B N J, Influence of surface roughness on adhesion between elastic bodies. Phys Rev Lett, 2005, 95(12): 124301

Scaraggi M, Carbone G, Dini D. Experimental evidence of micro-EHL lubrication in rough soft contacts. Tribol Lett, 2011, 43(2): 169–174

Scaraggi M, Carbone G, Persson B N J, et al. Lubrication in soft rough contacts: A novel homogenized approach. Part I-Theory. Soft Matter, 2011, 7: 10395–10406

Scaraggi M, Carbone G, Dini D. Lubrication in soft rough contacts: A novel homogenized approach. Part II-Discussion. Soft Matter, 2011, 7: 10407–10416

Krick B A, Vail J R, Persson B N J, et al. Optical in situ micro tribometer for analysis of real contact area for contact mechanics, adhesion and sliding experiments. Tribol Lett, 2012, 45(1): 185–194

Zhang J Y, Meng Y G. Direct observation of cavitation phenomenon and hydrodynamic lubrication analysis of textured surfaces. Tribol Lett, 2012, 46: 147–158

Deuk-Won L, Kwanghee L, Chul-Hee L. A study on the tribological characteristics of a magneto rheological elastomer. J Tribol, 2013, 135: 014501–1

Liu S H, Tan G B, Wang D G. Linear polymer aqueous solutions in soft lubrication: from boundary to mixed lubrication. Sci China Tech Sci, 2013, 56(7): 1709–1714

Zhang S W. State-of-the-art of polymer tribology. Tribol Int, 1998, 31: 49–60

Roberts A D. Squeeze films between rubber and glass. J Phys D: Appl Phys, 1971, 4(3): 423–432

Persson B N J. Theory of rubber friction and contact mechanics. J Chem Phys, 2001, 115(8): 3840–3861

Liu S H, Tan G B. Lubricating properties of oil-in-water emulsion with low oil concentration: Competitive wetting effect. Sci China Tech Sci, 2013, 56(2): 369–375

Murakami T, Yarimitsu S, Nakashima K, et al. Influence of synovial constituents on tribological behaviors of articular cartilage. Friction, 2013, 2: 150–162

Liu Y H, Xiao Y Q, Luo J B. Preparation of poly (N-isopropylacrylamide) brush bonded on silicon substrate and its water-based lubricating property. Sci China Tech Sci, 2012, 55(12): 3352–3358

Liu Y H, Wang X K, Liu P X, et al. Modification on the tribological properties of ceramics lubricated by water using fullerenol as a lubricating additive. Sci China Tech Sci, 2012, 55(9): 2656–2661

Liu S H, Guo D, Xie G X. Nanoscale lubricating film formation by linear polymer in aqueous solution. J Appl Phys, 2012, 112(10): 104301

Scaraggi M, Persson B N J. Time-dependent fluids queeze-out between soft elastic solids with randomly rough surfaces. Tribol Lett, 2012, 47(3): 409–416

Persson B N J, Tartaglino U, Albohr O, et al. Rubber friction on wet and dry road surfaces: Sealing effect. Phys Rev B, 2005, 71(3): 035428

Zhang S W. Green tribology: Fundamentals and future development. Friction, 2013, 2: 186–194

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Tan, G., Wang, D., Liu, S. et al. Frictional behaviors of rough soft contact on wet and dry pipeline surfaces: With application to deepwater pipelaying. Sci. China Technol. Sci. 56, 3024–3032 (2013). https://doi.org/10.1007/s11431-013-5398-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-013-5398-8