Abstract

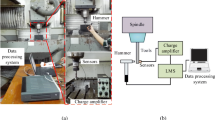

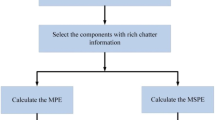

Cutting chatter is a violent self-excited vibration between a tool and a workpiece. Its negative effects mainly include poor surface quality, inferior dimensional accuracy, disproportionate tool wear or tool breakage, and excessive noise. Therefore, early recognition and online suppression of chatter vibration are necessary. This paper proposes a novel synthetic criterion (SC) for early chatter recognition. The proposed SC integrates standard deviation (STD) and one-step autocorrelation function (OSAF). Moreover, this paper revised the fast algorithm of OSAF. We can quantitatively divide a chatter vibration signal into three stages, which are stable stage, transition stage and chatter stage according to the SC. Compared with STD, the SC can improve the reliability of chatter recognition and the threshold of SC is not sensitive to variable cutting conditions. This paper presents an original algorithm of SC and its fast algorithm in detail. The fast algorithm of SC in this paper improves the computation efficiency compared with the original algorithm of SC. To validate the effectiveness of the proposed SC, a series of milling experiments were conducted under different cutting conditions. In these experiments, the vibration signals were acquired by two accelerometers mounted on the spindle house. The experimental results showed that the proposed SC could effectively recognize chatter vibration at an early stage of chatter vibration, which saved valuable time for online chatter suppression.

Similar content being viewed by others

References

Quintana G, Ciurana J. Chatter in machining processes: A review. Int J Mach Tools Manuf, 2011, 51: 363–376

Kuljanic E, Sortino M, Totis G. Multisensor approaches for chatter detection in milling. J Sound Vib, 2008, 312: 672–693

Siddhpura M, Paurobally R. A review of chatter vibration research in turning. Int J Mach Tools Manuf, 2012, 61: 27–47

Taylor F W. On the art of cutting metals. T ASME, 1907, 28: 3–248

Arnold R N. The mechanism of tool vibration in the cutting dynamics. Proc Ins Mech Eng, 1946, 54: 261–284

Tlusty J, Spacek M. Self-Excited Vibrations in Machine Tools. Prague: Publication of the Czech Academy of Sciences, 1954

Hahn R S. On the theory of regenerative chatter in precision grinding operations. T ASME B, 1954, 76(1): 593–597

Wiercigroch M, Budak E. Sources of nonlinearities, chatter generation and suppression in metal cutting. Proc R Soc London, 2001, 359: 663–693

Tobias S A, Fishwick W. Theory of regenerative machine tool chatter. The Engineer, 1958, 205: 199–203

Altintas Y, Budak E. Analytical prediction of stability lobes in milling. CIRP Ann-Manuf Techn, 1995, 44(1): 357–362

Altintas Y, Weck M. Chatter stability of metal cutting and grinding. CIRP Ann-Manuf Techn, 2004, 53(2): 619–642

Ding Y, Zhu L M, Zhang X J, et al. Milling stability analysis using the spectral method. Sci China Tech Sci, 2011, 54(12): 3130–3136

Insperger T, Stépán G, Bayly P V, et al. Multiple chatter frequencies in milling processes. J Sound Vib, 2003, 262: 333–345

Rahman M, Zhou Q, Hong G S. On-line cutting state recognition in turning using a neural network. Int J Adv Manuf Tech, 1995, 10(2): 87–92

Khalifa O O, Densibali A, Faris W. Image processing for chatter identification in machining processes. Int J Adv Manuf Tech, 2006, 31: 443–449

Kuljanic E, Totis G, Sortino M. Development of an intelligent multisensor chatter detection system in milling. Mech Syst Signal Proc, 2009, 23: 1704–1718

Liu H Q, Chen Q H, Li B, et al. On-line chatter detection using servo motor current signal in turning. Sci China Tech Sci, 2011, 54(12): 3119–3129

Schmitz T L, Davies M A, Medicus K, et al. Improving high-speed machining material removal rates by rapid dynamic analysis. CIRP ANN-Manuf Techn, 2001, 50: 263–268

Tangjitsitcharoen S. In-process monitoring and detection of chip formation and chatter for CNC turning. J Mater Proc Technol, 209(10): 4682–4688

Wang L, Liang M. Chatter detection based on probability distribution of wavelet modulus maxima. Robot CIM-INT Manuf, 2009, 25: 989–998

Yao Z H, Mei D Q, Chen Z C. On-line chatter detection and identification based on wavelet and support vector machine. J Mater Proc Technol, 2010, 210: 713–719

Chiou R Y, Liang S Y. Analysis of acoustic emission in chatter vibration with tool wear effect in turning. Int J Mach Tools Manuf, 2000, 40: 927–941

Xie F Y, Wu B, Hu Y M, et al. A generalized interval probability-based optimization method for training generalized hidden Markovmodel. Signal Process, 2014, 94(1): 319–329

Nair U, Krishna B M, Namboothiri V N N, et al. Permutation entropy based real-time chatter detection using audio signal in turning process. Int J Adv Manuf Tech, 2010, 46: 61–68

Grabec I, Gradisek J, Govekar E. A new method for chatter detection in turning. CIRP Ann-Manuf Techn, 1999, 48(1): 29–32

Soliman E, Ismail F. Chatter detection by monitoring spindle drive current. Int J Adv Manuf Tech, 1997, 13: 27–34

Mei Z J, Shi H M, Liu J Y, et al. An effective and comprehensive criterion for early stage diagnosis of chatter in metal cutting process (in Chinese). J Huazhong Instit Technol, 1985, 13(5): 87–94

Shi H M. Metal Cutting Theory and Practice: A New Perspective (in Chinese). Wuhan: Huazhong University of Science and Technology Press, 2003

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, G., Wu, B., Hu, Y. et al. A synthetic criterion for early recognition of cutting chatter. Sci. China Technol. Sci. 56, 2870–2876 (2013). https://doi.org/10.1007/s11431-013-5360-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-013-5360-9