Abstract

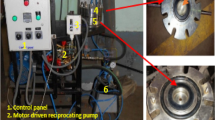

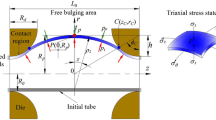

Superplastic alloy has very strong structure sensitivity. Superplastic bulging with a die of the plate is related not only to stress state but also closely to loading paths. It is an important basis for bulging forming with a die to study deformation law and experimental apparatus for superplastic free bulging, because the boundary of test piece is fixed and friction is insignificant for free bulging. In the paper, a pure high-pressure argon gas source is used as the loading media after it is heated by the heating system outside the furnace, which improves the heating efficiency and temperature uniformity of the test piece. The photoelectric non-contact measurement device can avoid negative influence on the additional stress and uneven temperature at the peak of bulging part caused by push rod in the contact measurement. The temperature and pressure of the test piece in cylindrical insulation furnace with blank holder give feedback control to improve the control precision. In loading gas channels, the pressure is adjusted by accurately measuring and controlling the rotation angle of the stepping motor, and is loaded by an electromagnetic valve. It significantly increases the response characteristics of the control pressure. This paper also introduces steps and methods to realize several typical loading paths, such as constant pressure, jump pressure and additional back & differential pressure loading. These provide a new way to measure the strain rate sensitivity index m value and improve the deformation speed of superplastic free bulging.

Similar content being viewed by others

References

Song Y Q, Zuo W Y. Mathematic models of thinning pattern for non-sphere superplastic free bulging (I). Sci China Ser A-Math Phys Astron, 1992, 35(1): 122–128

Song Y Q, Zuo W Y. Models of geometric profile for non-sphere superplastic free bulging (II). Sci China Ser A-Math Phys Astron, 1992, 35(2): 247–256

Song Y Q, Zuo W Y. The mechanical fields for superplastic free bulging (III). Sci China Ser A-Math Phys Astron, 1992, 35 (11): 1388–1401

Song Y Q, Liu S M. One-dimensional tensile constitutive equation cannot be directly generalized to deal with two-dimensional bulging mechanical problems. Sci China Ser E-Tech Sci, 2002, 32(3): 289–295

Jovane F. An approximate analysis of the superplastic forming of a thin circular diaphragm: Theory and experiment. Int J Mech Sci, 1968, 10: 403–427

Son Y Q, Zhao J, Wan S D. An experiment device of photoelectrical measurement for superplastic bulge of metal sheet. Met Sci Tech, 1985, 3(3): 89–94

Song Y Q, Lian S J. The formula of measuring m value in superplastic bulging by means of jump pressure. Chin Sci Bull, 1990, 35(16): 73–76

Song Y Q, Piao C C. Best technological specification of high speed superplastic bulging under back pressure. Chin Sci Bull, 1993, 39(7): 855–858

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, Y., Ma, P. & Guan, X. An accurate loading experimental measurement device for superplastic free bulging. Sci. China Technol. Sci. 56, 2109–2114 (2013). https://doi.org/10.1007/s11431-013-5299-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-013-5299-x