Abstract

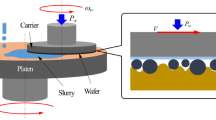

A finite element analysis (FEA) model is developed for the chemical-mechanical polishing (CMP) process on the basis of a 12-in five-zone polishing head. The proposed FEA model shows that the contact stress non-uniformity is less dependent on the material property of the membrane and the geometry of the retaining ring. The larger the elastic modulus of the pad, the larger contact stress non-uniformity of the wafer. The applied loads on retaining ring and zone of the polishing head significantly affect the contact stress distribution. The stress adjustment ability of a zone depends on its position. In particular, the inner-side zone has a high stress adjustment ability, whereas the outer-side zone has a low stress adjustment ability. The predicted results by the model are shown to be consistent with the experimental data. Analysis results have revealed some insights regarding the performance of the multi-zone CMP.

Similar content being viewed by others

References

Preston F W. The theory and design of plate glass polishing machine. J Soc Glass Technol, 1927, 11: 214–256

Runnels S R, Kim I, Schleuter J, et al. Modelling tool for chemical-mechanical polishing design and evaluation. IEEE T Semicond M, 1998, 11(3): 501–510

Wang D, Lee J, Holland K, et al. Von Mises stress in chemical-mechanical polishing process. J Electrochem Soc, 1997, 144(3): 1121–1127

Lin Y Y, Lo S P. Finite element modeling for chemical mechanical polishing process under different back pressures. J Mater Process Technol, 2003, 140: 646–652

Lo S P, Lin Y Y. The prediction of wafer surface non-uniformity using FEM and ANFIS in the chemical mechanical polishing process. J Mater Process Technol, 2005, 168: 250–257

Fu G, Chandra A. The relationship between wafer surface pressure and wafer backside loading in chemical mechanical polishing. Thin Solid Films, 2005, 474: 217–221

Shiu S J, Yu C C, Shen S H. Multivariable control of multizone chemical mechanical polishing. J Vac Sci Technol B, 2004, 22(4): 1679–1687

Wang Y C. Numerical simulation and process parameter study for chemical mechanical planarization. Dissertation for Doctor Degree. Tainan: National Cheng Kung University, 2008

Chen K S, Yeh H M, Yan J L, et al. Finite-element analysis on wafer-level CMP contact stress reinvestigated issues and the effects of selected process parameters. Int J Adv Manuf Technol, 2008, 42: 1118–1130

Lin Y Y. Influence of a retaining ring on strain and stress in the chemical mechanical polishing process. Mater Manuf Process, 2007, 22: 871–878

Wang T Q, Lu X C. Numerical and experimental investigation on multi-zone chemical mechanical planarization. Microelectron Eng, 2011, 88: 3327–3332

Murthy C S, Wang D, Beaudoin S, et al. Non-uniformity in CMP process: An effect of stress. In: Proceedings of the CMP-MIC Conference, 1997

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, T., Lu, X., Zhao, D. et al. Contact stress non-uniformity of wafer surface for multi-zone chemical mechanical polishing process. Sci. China Technol. Sci. 56, 1974–1979 (2013). https://doi.org/10.1007/s11431-013-5245-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-013-5245-y