Abstract

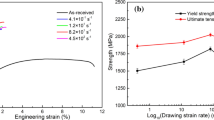

The evolution of morphology of pearlite and crystallographic texture of ferrite matrix in fully pearlitic steels during wire drawing were quantitatively investigated. The study revealed that a fiber structure of the pearlite morphology and a <110> fiber texture of the ferrite matrix begin to take shape and develop gradually with increasing strain. The growth rates of the fiber structure and the <110> texture are different in different regions within the wires with increasing drawing strain. There is a close relationship between the pearlite morphology and the crystalline texture during wire drawing. The pearlite interlamellar spacing (ILS) and thickness of cementite lamellae (T θ) decrease gradually both in longitudinal and transverse sections. The definition of pearlite colony should be reconsidered for describing microstructure of the wire drawing deformed pearlitic steels.

Similar content being viewed by others

References

Embury J D, Fisher R M. The structure and properties of drawn pearlite. Acta Metall, 1966, 4: 147–159

Langford G. A study of the deformation of patented steel wire. Metall Trans, 1970, 1(2): 65–77

Langford G. Deformation of pearlite. Metall Trans A, 1977, 8(6): 861–875

Marder A, Bramfitt B. The effect of morphology on the strength of pearlite. Metall Mater Trans A, 1976, 7: 365–372

Zelin M. Microstructure evolution in pearlitic steels during wire drawing. Acta Mater, 2002, 50: 4431–4447

Toribio J, Ovejero E. Effect of cumulative cold drawing on the pearlite interlamellar spacing in eutectoid steel. Scripta Mater, 1998, 39: 323–328

Toribio J, González B, Matos J C. Fatigue crack propagation in cold drawn steel. Mater Sci Eng A, 2007, 468]2-470: 267–272

Zhang X D, Godfrey A, Hansen N, et al. Evolution of cementite morphology in pearlitic steel wire during wet wire drawing. Mater Charact, 2010, 61: 5–72

Zhang X D, Godfrey A, Huang X, et al. Microstructure and strengthening mechanisms in cold-drawn pearlitic steel wire. Acta Mater, 2011, 59: 3422–3430

Languillaume J, Kapelski G, Baudelet B. Cementite dissolution in heavily cold drawn pearlitic steel wires. Acta Mater, 1997, 45: 1201–1212

Danoix F, Julien D, Sauvage X, et al. Direct evidence of cementite dissolution in drawn pearlitic steels observed by tomographic atom probe. Mater Sci Eng A, 1998, 250: 8–13

Ivanisenko Y, Lojkowski W, Valiev R Z, et al. The mechanism of formation of nanostructure and dissolution of cementite in a pearlitic steel during high pressure torsion. Acta Mater, 2003, 51: 5555–5570

Hono K, Ohnuma M, Murayama M, et al. Cementite decomposition in heavily drawn pearlite steel wire. Scripta Mater, 2001, 44: 977–983

Underwood E E. Quantitative Stereology. Reading, MA: Addison-Wesley, 1970. 3–75

Hu X H, Van Houtte P, Liebeherr M, et al. Modeling work hardening of pearlitic steels by phenomenological and Taylor-type micromechanical models. Acta Mater, 2006, 54: 1029–1040

Guo N, Liu Q, Xin Y C, et al. The application of back-scattered electron imaging for characterization of pearlitic steels. Sci China Tech Sci, 2011, 54: 2368–2372

Guo N, Liu Q. Back-scattered electron imaging combined with EBSD technique for characterization of pearlitic steels. J Microsc, 2012, 246(3): 221–228

Zhang X D, Godfrey A, Liu W, et al. Evolutions of microstructure and ferritic micro-orientation and texture in a pearlitic steel wire during cold drawing. Acta Mater Sin, 2010, 46: 141–146

Hu H. Texture of metals. Texture, 1974, 1: 233–258

Garbarz B, Pickering F B. Effect of pearlite morphology on impact toughness of eutectoid steel containing vanadium. Mater Sci Technol, 1988, 4: 328–334

Caballero F G, Capdevila C, García de Andrés C. Modeling of the interlamellar spacing of isothermally formed pearlite in a eutectoid steel. Scripta Mater, 2000, 42: 537–542

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, N., Luan, B., Wang, B. et al. Microstructure and texture evolution in fully pearlitic steel during wire drawing. Sci. China Technol. Sci. 56, 1139–1146 (2013). https://doi.org/10.1007/s11431-013-5184-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-013-5184-7