Abstract

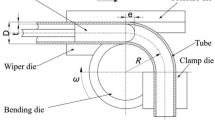

As one kind of key lightweight components with enormous quantities and diversities, the bent tubular parts have attracted increasing applications in aerospace, automobile, etc. Thus, how the inevitable springback behaves under different bending specifications should be fully addressed to efficiently achieve the precision forming of various bent tubes. Taking the medium strength thin-walled 6061-T4 Al-alloy tube as the objective, via the deformation theory of plasticity, explicit/implicit FE method and experimental approaches, we explored and clarified the nonlinear springback rules of the tubes and corresponding mechanisms in universal rotary draw bending regarding angular springback and radius growth by deliberately changing the tube diameter D and wall thickness t. The geometry dependent springback behaviors of thin-walled tube upon cold bending are thus revealed: 1) With the increasing of D, the tangent tensile strain increases and the proportional coefficient decreases, which causes the angular springback to decrease, while the radius springback increases due to the larger bending radius. 2) With the increasing of t, the tangent tensile strain decreases and the proportional coefficient increases, resulting in the increase of both angular springback and radius springback. 3) Under the same D/t, the angular springback varies little, while the radius springback increases with the larger diameter D. 4) The D/t can be used as a reasonable nondimensional index to evaluate the springback angle; as to the radius growth, the individual effects of the D and t should be considered. 5) The verification of the above results was conducted by experiments and analytical analysis.

Similar content being viewed by others

References

Welo T. Sheet Metal Forming. In: Francisco Chinesta and Elias Cueto, Advances in Material Forming (Esaform 10 years on), Paris: Springer. 2007. 175–191

Department of Engineering and Material Science, NSFC. Development Strategy Report of Mechanical Engineering Discipline (2011–2020) (in Chinese). Beijing: Science Press, 2010

Yang H, Li H, Zhang Z Y, et al. Advances and trends on tube bending forming technologies. Chin J Aeronaut, 2012, 25: 1–12

Yang H, Ren N, Zhan M, et al. Experimental and numerical studies on the prediction of bendability limit of QSTE340 welded tube in NC bending process. Sci China Tech Sci, 2012, 55: 2264–2277

Corona E, Lee L H, Kyriakids S. Yield anisotropy effects on buckling of circular tubes under bending. Int J Solid Struct, 2006, 43: 7099–7118

Li H, Yang H, Zhan M. A study on plastic wrinkling in thin-walled tube bending via an energy-based wrinkling prediction model. Modelling Simul. Mater Sci Eng, 2009, 17: 035007

Liu Y, Day M L. Bending collapse of thin-walled circular tubes and computational application. Thin Wall Struct, 2008, 46: 442–450

Li H, Yang H, Zhan M, et al. Role of mandrel in NC precision bending process of thin-walled tube. Int J Mach Tools Manuf, 2007, 47: 1164–1175

Yan J, Yang H, Zhan M, et al. Forming limits under multi-index constraints in NC bending of aluminum alloy thin-walled tubes with large diameters. Sci China Tech Sci, 2010, 53(2): 326–342

Li H, Yang H, Yan J, et al. Numerical study on deformation behaviors of thin-walled tube NC bending with large diameter and small bending radius. Comp Mater Sci, 2009, 45: 921–934

Lim H, Lee M G, Sung J H, et al. Time-dependent springback of advanced high strength steels. Int J Plasticity, 2012, 29: 42–59

Li K P, Carden W P, Wagoner R H. Simulation of springback. Int J Mech Sci, 2002, 44: 103–122

Karafillis A P, Boyce M C. Tooling and binder design for sheet metal forming processes compensating springback error. Int J Mach Tools Manuf, 1996, 36: 503–526

Zhao J, Yin J, Ma R, et al. Springback equation of small curvature plane bending. Sci China Tech Sci, 2011, 54: 2386–2396

Lou H Z, Stelson K A. Three-dimensional tube geometry control for rotary draw tube bending, Part 1: Bend angle and overall tube geometry control. J Manuf Sci Eng, 2001, 123: 258–265

Wu W, Zhang P, Zeng X Q, et al. Bendability of the wrought magnesium alloy AM30 tubes using a rotary draw bender. Mater Sci Eng A, 2008, 486(1–2): 596–601

Tang N C. Plastic-deformation analysis in tube bending. Int J Pres Ves Pip, 2000, 77: 751–759

Al-qureshi H A. Elastic-plastic analysis of tube bending. Int J Mach Tools Manuf, 1999, 39: 87–104

Zhan M, Yang H, Huang L, et al. Springback analysis of numerical control bending of thin-walled tube using numerical-analytic method. J Mater Process Technol, 2006, 177: 197–201

Gu R J, Yang H, Zhan M, et al. Research on the springback of thin-walled tube NC bending based on the numerical simulation of the whole process. Comp Mater Sci, 2008, 42: 537–549

Jiang Z Q, Yang H, Zhan M, et al. Coupling effects of material properties and the bending angle on the springback angle of a titanium alloy tube during numerically controlled bending. Mater Des, 2010, 31: 2001–2010

Zhan M, Jiang Z Q, Yang H, et al. Numerically controlled bending performance of medium strength TA18 titanium alloy tubes under different die sets. Sci China Tech Sci, 2011, 54: 841–852

E D X, Liu Y. Springback and time-dependent springback of 1Cr18Ni9Ti stainless steel tubes under bending. Mater Des, 2010, 31: 1256–1261

SAE Aerospace material specification. AMS-WW-T-700/6A. Tube, aluminum alloy, drawn, seamless, 6061, 2007

Yang H, Li H, Zhan M. Friction role in bending behaviors of thin-walled tube in rotary-draw-bending under small bending radii. J Mater Process Technol, 2010, 210: 2273–2284

E D X, Guo X D, Ning R X. Analysis of strain neutral layer displacement in tube-bending process (in Chinese). J Mech Eng, 2009, 45(3): 307–310

Mathworks product documents. 2011

Li H, Yang H. A study on multi-defect constrained bendability of thin-walled tube NC bending under different clearance. Chin J Aeronaut, 2011, 24: 102–112

Narasimhan N, Lovell M. Predicting springback in sheet metal forming: an explicit to implicit sequential solution procedure. Finite Elem Anal Des, 1999, 33: 29–42

ABAQUS Analysis User’s Manual. Version 6.7. 2007

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, H., Yang, H., Tian, Y. et al. Geometry-dependent springback behaviors of thin-walled tube upon cold bending. Sci. China Technol. Sci. 55, 3469–3482 (2012). https://doi.org/10.1007/s11431-012-5001-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-012-5001-8