Abstract

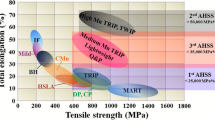

In order to meet the progressive requirement for the performance improvement of steel, the author proposed a novel microstructure featured with multi-phase, meta-stable and multi-scale (so-called as M3). And then, the new technologies could be developed to process three prototype steels with high performance: the third generation high strength low alloy (HSLA) steels with improved toughness and/or ductility (AKV(−40°C)⩾200 J and/or A⩾20% when Rp0.2 in 800–1000 MPa), the third generation advanced high strength steels (AHSS) (Rm×A⩾30 GPa% when Rm from 1000 MPa to 1500 MPa) for automobiles with improved ductility and low cost, and heat resistant martensitic steels with improved creep strength (σ10000650⩾90 MPa). It can be expected that the new technology developed will remarkably improve the safety and reliability of steel products in service for infrastructures, automobiles and fossil power station in the future.

Similar content being viewed by others

References

Dong H, Wang M Q, Weng Y Q. Performance improvement of steels trough M3 structure control. Iron Steel, 2010, 45(7): 1–7

Brenner S S. The growth of whiskers by the reduction of metal saltsLa croissance de barbes par la reduction de sels metalliques Das wachsen von “whiskers” durch reduktion von metallsalzen. Acta Metall, 1956, 4: 62–74

Dong H, Sun X J, Cao W Q, et. al, On the performance improvement of steels through M3 structure control. Advanced Steels. In: Weng Y Q, Dong H, Gan Y, eds. Beijing: Metallurgical Industry Press, 2010. 35–57

Weng Y Q. Ultra-fine Grained Steels. Beijing: Metallurgical Industry Press, 2008

Dong H, Sun S J, Hui W J, et al. Grain refinement in steels and the applications trials in China. ISIJ Int, 2008, 48: 1126–1132

Pontremoli M. Metallurgical and technological challenges for the development of high-performance X100-X120 linepipe steels. In: Proceeding of the second international conference on advanced structural steels (ICASS 2004), Shanghai, China, 2004. 39

Ashby M F. The deformation of plastically nonhomogeneous materials. Philos Mag, 1970, 21: 399–424

Torizukai O S, Nagai K. Strain-hardening due to dispersed cementite for low carbon ultrafine-grained steels. ISIJ Int, 2004, 44(6): 1063–1071

Wang X H, Jiang M, Chen B, et al. Study on formation of non-metallic inclusions with lower melting temperatures in extra low oxygen special steels. Sci China Tech Sci, 2012, 55: 1863–1872

Anderson D. Application and repairability of advanced high-strength steels. American Iron and Steel Institute, 2008, http://www.auto-steel.org

Heimbuch R. Overview: Auto/Steel partnership, www.a-sp.org

Jacques P, Furnemont Q, Mertens A, et al. On the sources of work hardening in multiphase steels assisted by transformation-induced plasticity. Phil Mag A, 2001, A81(7): 1789–1812

Frommeyer G, Brux U, Neumann P. Supra-ductile and high-strength manganese-TRIP/TWIP steels for high energy absorption purposes. ISIJ Int, 2003, 43(3): 438–446

Garcia-Mateo C, Caballero F G. Ultra-high-strength bainitic steels ISIJ Int, 2005, 45(11): 1736–1740

Shi J, Cao W Q, Dong H. Ultrafine grained high strength low alloy steel with high strength and high ductility. Mater Sci Forum, 2010, 654–656: 238–241

Cao W Q, Wang C Y, Shi J, et al. Application of quenching and partitioning to improve the ductility of ultrahigh strength low alloy steel. Mater Sci Forum, 2010, 654–656: 29–32

Wang C Y, Shi J, Cao W Q, et al. Characterization of microstructure obtained by quenching and partitioning process in low alloy martenstic steel. Mater Sci Eng A, 2010, 527: 3442–3449

Wang C Y, Shi J, Cao W Q, et al. Study on the martensite in low carbon CrNi3Si2MoV steel treated by Q&P process. Acta Metall Sin, 2011, 47(6): 720–726

Speer J G, Hackenberg R E, DeCooman B C, et al. Interface migration during annealing of martensite/austenite mixture. Phil Mag Lett, 2007, 87: 379–382

Speer J G, Matlock D K, Cooman B C, et al. Carbon partitioning into austenite after martensite transformation. Acta Mater, 2003, 51: 2611–2622

Miller R L. Ultrafine-grained microstructures and mechanical properties of alloy steels. Met Mater Trans A, 1972, 3: 905

Wang C Y. Investigation on 30 GPa% grade ultrahigh-strength martensitic-austenitic steels. Degree of Doctor Dissertation. Beijing: Central Iron & Steel Research Institute, 2010

Gazder A A, Cao W Q, Davies C H J. An EBSD investigation of interstitial-free steel subjected to equal channel angular extrusion. Mater Sci Eng A, 2008, 497: 341–352

Davies R G. The deformation behavior of a vanadium-strengthened dual phase steel. Metall Mater Trans A, 1978, 9: 41–52

Davies R G. Influence of martensite composition and content on the properties of dual phase steels. Metall Trans, 1978, 9A: 671–679

Slycken J V, Verleysen P, Degrieck J, et al. Dynamic response of aluminium containing TRIP steel and its constituent phases. Mater Sci Eng A, 2007, 460–461: 516–524

Grajcar A, Krztoń H. Effect of isothermal bainitic transformation temperature on retained austenite fraction in C-Mn-Si-Al-Nb-Ti TRIP-type steel. J Achievements Mater Manuf Eng, 2009, 35: 169–176

Grajcar A. Determination of the stability of retained austenite in TRIP-aided bainitic steel. J Achievements Mater Manuf Eng, 2007, 20: 111–114

Muránsky O, Horňak P, Lukáš P, et al. Investigation of retained austenite stability in Mn-Si TRIP steel in tensile deformation condition. J Achievements Mater Manuf Eng, 2006, 14: 26–29

Zackay V F, Parker E R, Fahr D. The enhancement of ductility in high-strength steels. Trans ASM, 1967, 60(2): 252–259

Humphreys F J, Hatherly M. Recrystallization and Related Annealing Phenomena. 2nd ed. Pergamon, 2004

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, H. High performance steels: Initiative and practice. Sci. China Technol. Sci. 55, 1774–1790 (2012). https://doi.org/10.1007/s11431-012-4911-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-012-4911-9