Abstract

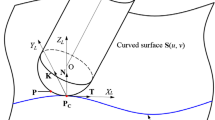

Traditional five-axis tool path planning methods mostly focus on differential geometric characteristics between the cutter and the workpiece surface to increase the material removal rate (i.e., by minimizing path length, improving curvature matching, maximizing local cutting width, etc.). However, material removal rate is not only related to geometric conditions such as the local cutting width, but also constrained by feeding speed as well as the motion capacity of the five-axis machine. This research integrates machine tool kinematics and cutter-workpiece contact kinematics to present a general kinematical model for five-axis machining process. Major steps of the proposed method include: (1) to establish the forward kinematical relationship between the motion of the machine tool axes and the cutter contact point; (2) to establish a tool path optimization model for high material removal rate based on both differential geometrical property and the contact kinematics between the cutter and workpiece; (3) to convert cutter orientation and cutting direction optimization problem into a concave quadratic planning (QP) model. Tool path will finally be generated from the underlying optimal cutting direction field. Through solving the time-optimal trajectory generation problem and machining experiment, we demonstrate the validity and effectiveness of the proposed method.

Similar content being viewed by others

References

Lee Y S, Ji A H. Surface interrogation and machining strip evaluation for 5-Axis CNC die and mold machining. Int J Production Res, 1997, 28: 225–252

Chiou C J, Lee Y S. A machining potential field approach to tool path generation for multi-axis sculptured surface machining. Computer-Aided Design, 2002, 34: 357–371

Rao N, Ismail F, Bedi S. Tool path planning for five-axis machining using the principal axis method. Int J Machine Tools Manuf, 1997, 37: 1025–1040

Wang X C, Li Y B, Chosh S K, et al. Curvature catering — a new concept for machineing sculptured surfaces. J Xi’an Jiaotong Univ, 1992, 26: 51–58, 109–110

Gong H, Cao L X, Liu J. Second order approximation of tool envelope surface for 5-axis machining with single point contact. Comput-Aided Design, 2008, 40(5): 604–615

Zhu L M, Ding H, Xiong Y L. Third-order point contact approach for five-axis sculptured surface machining using non-ball-end tools (I): Third-order approximation of tool envelope surface. Sci China Tech Sci, 2010, 53: 1904–1912

Zhu L M, Ding H, Xiong Y L. Third-order point contact approach for five-axis sculptured surface machining using non-ball-end tools (II): Tool positioning strategy. Sci China Tech Sci, 2010, 53: 2190–2197

Griffiths J G. Toolpath based on Hilbert’s curve. Computer-Aided Design, 1994, 26: 839–844

Cox J J, Takezaki Y, Ferguson H R P, et al. Space-filling curves in tool-path applications. Computer-Aided Design, 1994, 26: 215–224

Anotaipaiboon W, Makhanov S S. Tool path generation for five-axis NC machining using adaptive space-filling curves. Int J Production Res, 2005, 43: 1643–1665

Zhu L M, Zheng G, Ding H. Formulating the swept envelope of rotary cutter undergoing general spatial motion for multi-axis nc machining. Int J Machine Tools Manuf, 2009, 49(2): 199–202

Zhang X M, Zhu L M, Zheng G, et al. Tool path optimization for flank milling ruled surface based on distance function. Int J Production Res, 2010, 48(14): 4233–4251

Ding H, Zhu L M. Global optimization of tool path for five-axis flank milling with a cylindrical cutter. Sci China Ser E-Tech Sci, 2009, 52(8): 2449–2459

Makhanov S S, Ivanenko S A. Grid generation as applied to optimize cutting operations of the five-axis milling machine. Appl Numer Math, 2003, 46: 331–351

Kim T, Son S, Sarma S E. On actuator reversal motions of machine tools. Mecha Machine Theory, 2004, 39: 299–322

Bi Q Z, Wang Y H, Zhu L M, et al. Generating collision-free tool orientations for 5-axis nc machining with a short ball-end cutter. Int J Production Res, 2010, 48(24): 7337–7356

Bi Q Z, Wang Y H, Zhu L M, et al. Wholly smoothing cutter orientations for five-axis NC machining based on cutter contact point mesh. Sci China Tech Sci, 2010, 53: 1294–1303

Kim T, Sarma S E. Optimal sweeping paths on a 2-manifold: A new class of optimization problems defined by path structures. IEEE Trans Robot Autom, 2003: 613–636

Montana D J. The kinematics of contact and grasp. Int J Robot Res, 1988, 7: 17–32

Murray R M, Li Z, Sastry S S. A Mathematical Introduction to Robotic Manipulation, Boca Raton FL: CRC Press, 1994

Nelson D, Cohen E. Optimization-based virtual surface contact manipulation at force control rates. Proceedings of the IEEE Virtual Reality 2000 Conference. Washington DC: IEEE, 2000

Anitescu M, Cremer J F, Potra F A. Formulating 3D contact dynamics problems. Mech Struct Mach, 1996, 24: 405–437

Antoniou A, Lu W. Practical Optimization: Algorithms and Engineering Applications, New York: Springer, 2007

Chinchuluun A, Pardalos P, Enkhbat R. Global minimization algorithms for concave quadratic programming problems. Optimization, 2005, 54: 627–639

Park F, Ravani B. Smooth invariant interpolation of rotations. ACM Trans Graphics, 1997, 16: 277–295

Makhanov S. Optimization and correction of the tool path of the five-axis milling machine Part 1. Spatial optimization. Math Comput Simul, 2007, 75: 210–230

Ding Y, Zhu L M, Zhang X J, et al. Milling stability analysis using the spectral method. Sci China Tech Sci, 2011, 54: 3130–3136

Zhang X J, Xiong C H, Ding Y, et al. Variable-step integration method for milling chatter stability prediction with multiple delays. Sci China Tech Sci, 2011, 54: 3137–3154

Mao X Y, Liu H Q, Li Bin. Time-frequency analysis and the detecting method research on the milling force token signal in the spindle current signal. Sci China Ser E-Tech Sci, 2009, 52: 2810–2813

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ye, T., Xiong, C., Xiong, Y. et al. Kinematics constrained five-axis tool path planning for high material removal rate. Sci. China Technol. Sci. 54, 3155–3165 (2011). https://doi.org/10.1007/s11431-011-4605-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4605-8