Abstract

Nanoindentation technique was adopted to investigate the chemomechanical properties change of hardened cement paste before and after carbonation. It was found that the mean elastic modulus and mean hardness obviously increase after the carbonation reaction. Specifically, the probability of the elastic modulus showed a sharp reduction for the elastic modulus at the range of 7–34 and 83–160 GPa, in comparison of a large increase for the elastic modulus between 34–83 GPa. For the same reason, the probability of the hardness showed a large decrease when the hardness fell within 0.15–1.75 and 4.15–8.20 GPa and a dramatic increase for the hardness at the range of 1.75–4.15 GPa. In addition, low density C-S-H was affected by the carbonation degradation more seriously than high density C-S-H. The carbonation reaction led to distinct decrease of the number and size of unhydrated cement paste particles.

Similar content being viewed by others

References

Ishida T, Maekawa K, Soltani M. Theoretically identified strong coupling of carbonation rate and thermodynamic moisture states in micropores of concrete. JACT, 2004, 2: 213–222

Papadakis V G, Vayenas C G, Fardis M N. Fundamental modeling and experimental investigation of concrete carbonation. ACI Mater J, 1991, 88: 363–373

Papadakis V G, Vayenas C G, Fardis M N. Experimental investigation and mathematical modeling of the concrete carbonation problems. Chem Eng Sci, 1991, 46: 1333–1338

Han J D, Pan G H, Sun W. Investigation on carbonation induced meso-defects changes of cement mortar using 3D X-ray computed tomography. J Chinese Ceramic Society, 2011, 39: 75–79

Rozière E, Loukili A, Cussigh F. A performance based approach for durability of concrete exposed to carbonation. Constr Build Mater, 2009, 23: 190–199

Ba M F, Qian C X, Gao G B. Influence of absolute basicity and capillary porosity on carbonation of concrete. J Wuhan Univ Technol-Mater Sci Ed, 2010, 25: 889–892

Constantinides G, Ulm F J, Vliet K V. On the use of nanoindentation for cementitious materials. Mater Struct, 2002, 36: 191–196

Velez K, Maximilien S, Damodot D, et al. Determination by nanoindentation of elastic modulus and hardness of pure constituents of Portland cement clinker. Cem Concr Res, 2001, 31: 555–561

Constantinides G, Ulm F J. The effect of two types of C-S-H on the elasticity of cement-based materials: Results from nanoindentation and micromechanical modeling. Cem Concr Res, 2004, 34: 67–80

Jennings H M, Thomas J J, Gevrenov J S, et al. A multi-technique investigation of nanoporosity of cement paste. Cem Concr Res, 2007, 37: 329–336

Zhu W, Hughes J J, Bicanic N, et al. Nanoindentation mapping of mechanical properties of cement paste and natural rocks. Mater Charact, 2007, 58: 1189–1198

Dejong M J, Ulm F J. The nanogranular behavior of C-S-H at elevated temperatures (up to 700°C). Cem Concr Res, 2007, 37: 1–12

Mondal P, Shah S P, Marks L. A reliable technique to determine the local mechanical properties at nanoscale for cementitious materials. Cem Concr Res, 2007, 37: 1440–1444

Maria S G K, Metaxa Z S, Shah S P. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube cement nanocomposites. Cem Concr Compos, 2010, 32: 110–115

Çdpuroğlu O, Schlangen E. Modeling of frost salt scaling. Cem Concr Res, 2008, 38: 27–39

James V. A Nanochemomechanical Investigation of Carbonated Cement Paste. Dissertation of Doctoral Degree. Massachusetts: Massachusetts Institute of Technology, 2009

Xiao H W, Jacobsen S, Jian Y H, et al. Application of nanoindentation testing to study of the interfacial transition zone in steel fiber reinforced mortar. Cem Concr Res, 2008, 39: 701–715

Mondal P, Shah S P, Marks L. Nanoscale characterization of cementitious materials. ACI Mater J, 2008, 105: 174–179

Oliver W C, Pharr G M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res, 1992, 7: 1564–1583

Oliver W C, Pharr G M. On the generality of the relationship among contact stiffness, contact area and elastic modulus during indentation. J Mater Res, 1992, 7: 613–617

Sorelli L, Constantinides G, Ulm F J, et al. The nano-mechanical signature of ultra high performance concrete by statistical nanoindentation techniques. Cem Concr Res, 2008, 38: 1447–1456

Constantinides G, Ulm F J. The nanogranular nature of C-S-H. J Mech Phys Solids, 2007, 55: 64–90

Pharr G M, Bolshakov A. Understanding nanoindentation unloading curves. J Mater Res, 2002, 17: 2660–2671

Nemecek J. Creep effects in nanoindentation of hydrated phases of cement pastes. Mater Charact, 2009, 60: 1028–1034

Ulm F J, Vandamme M, Jennings H M, et al. Does microstructure matter for statistical nanoindentation techniques? Cem Concr Compos, 2010, 32: 92–99

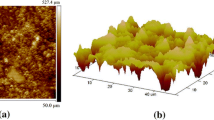

Miller M, Bobko C, Vandamme M, et al. Surface roughness criteria for cement paste nanoindentation. Cem Concr Res, 2008, 38: 467–476

Acker P. Micromechanical analysis of creep and shrinkage mechanisms. Creep, Shrinkage and Durability Mechanics of Concrete and Other Quasi-Brittle Materials, Oxford, UK, 2001. 15-25

Constantinides G, Ulm F J. The Elastic Properties of Calcium Leached Cement Pastes and Mortars: A Multi-scale Investigation. MIT CEE Report R02-01, 2006

Beaudoin J. Comparison of mechanical properties of compacted calcium hydroxide and Portland cement paste systems. Cem Concr Res, 2008, 13: 319–324

Wittmann F H. Estimation of the modulus of elasticity of calcium hydroxide. Cem Concr Res, 2008, 16: 971–972

Monteiro P J M, Chang C T. The elastic-modulus of calcium hydroxide. Cem Concr Res, 1995, 25: 1605–1609

Yang T, Keller B, Magyari E. Direct observation of the carbonation process on the surface of calcium hydroxide crystals in hardened cement paste using an atomic force microscope. J Mater Sci, 2003, 38: 1909–1916

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, J., Pan, G., Sun, W. et al. Application of nanoindentation to investigate chemomechanical properties change of cement paste in the carbonation reaction. Sci. China Technol. Sci. 55, 616–622 (2012). https://doi.org/10.1007/s11431-011-4571-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4571-1