Abstract

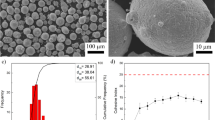

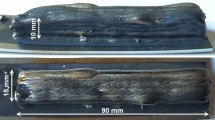

By means of electron backscattering diffraction and transmission electron microscopy the microstructure and texture of drawn single crystal copper with initial orientation 〈110〉 parallel to axial direction have been investigated in the present work. In order to analyze the effect of initial orientation on microstructure and texture of drawn copper, the results of the drawn 〈100〉 single crystal copper wires have been compared with 〈110〉 and 〈111〉 single crystal copper wires. It is found that the grain subdivision of 〈110〉 single crystal is more evident than that of 〈100〉 and 〈111〉, and the textures consisting of 〈111〉 and 〈100〉 abruptly form in the drawn 〈110〉 single crystal. At high strains, due to shear strain, the distribution of fiber textures is imhomogenous along the radial direction of drawn 〈110〉 single crystal copper wires. 〈100〉 is near the surface and 〈111〉 is at the center. The microstructure results of drawn 〈110〉 single crystal show that at low strains, it can be characterized as two kinds of geometrically necessary boundaries with noncrystalline character. At medium strains, S bands can be observed. At high strains, lamellar boundaries form. Mean misorientation and average spacing of dislocation boundary are larger in drawn 〈110〉 single crystal, as compared with 〈111〉 and 〈100〉. In drawn 〈110〉 single crystal with high strains, the bimodal distribution forms at lower strains than in drawn 〈100〉 single crystal, which is because the dislocation boundaries with high angle are contributed by not only the boundary between 〈111〉 and 〈100〉 fiber textures but also the boundary in 〈111〉 or 〈100〉 texture.

Similar content being viewed by others

References

Ohno A. Continuous casting of single crystal ingots by O.C.C process. J Metals, 1986, 38: 14–19

Yan W, Chen J, Fan X H. Effects of grain boundaries on the electri cal property of copper wires. Trans Nonferrous Met Soc China, 2003, 13: 1075–1079

Fan X H, Li J G, Fu H Z. Effect of L/S interface on surface quality of CCSC (in Chinese). Chin J Mater Res, 1999, 13: 320–322

Chen J, Yan W, Fan X H, et al. The technique of producing the single crystal metal wires with small diameter (in Chinese). J Xi’an Institute Technol, 2004, 24: 280–283

Soda H, Mclean A, Wang Z, et al. Pilot-scale casting of single-crystal copper wires by the Ohno continuous casting process. J Mater Sci, 1995, 30: 5438–5448

Shin H J, Jeong H T, Lee D N. Deformation and annealing textures of silver wire. Mater Sci Eng A, 2000, 279: 244–253

Rajian K, Petkie R. Microtexture and anisotropy in wire drawn copper. Mater Sci Eng A, 1998, 257: 185–197

Hibbard W R. Deformation texture of drawn face centered cubic metal wires. Trans AIME, 1950, 77: 581–585

McHargue C J, Jetter L K, Ogle J C. Preferred orientation in extruded aluminum rod. Trans TMS-AIME, 1959, 215: 831–837

Ahlborn H, Wassermann G. Einfluβ von verformungsgrad und-temperature auf die textur von silberdrähten. Z Metall, 1963, 54: 1–6

Stout M G, Kallend J S, Kocks U F, et al. Material dependence of deformation texture in various deformation modes. In: Kallend J S, Gottstein G, ed. Proceedings of the 8th International Conference on Textures of Materials, ICOTOM-8, The Metallurgical Society, 1998. 479–84

English A T, Chin G Y. On the variation of wire texture with stacking fault energy in f.c.c. metals and alloys. Acta Metall, 1965, 13: 1013–6

Chen J, Yan W, Wang X Y, et al. Microstructure evolution of drawn single crystal wires in cold drawing. Sci China Ser E-Tech Sci, 2007, 50: 736–748

Chen J, Yan W, Ding R G, et al. Dislocation boundaries in drawn single crystal copper wires produced by Ohno continuous casting. J Mater Sci, 2009, 44: 1909–1917

Chen J, Yan W, Miao J, et al. Microstructure and texture evolution of cold drawn 〈111〉 single crystal copper. Metall Mater Trans A, 2011, DOI: 10.1007/s11661-011-0654-7

Park H, Lee D H. Effects of shear strain and drawing pass on the texture development in copper wire. Mater Sci Forum, 2002, 408–412: 637–42

Park H, Lee D H. Evolution of annealing textures in 90 Pct drawn copper wire. Metall Mater Trans A, 2003, 34: 531–41

Sakharova N A, Fernandes J V. Strain path change effect on dislocation microstructure of polycrystalline copper sheets. Mater Chem Phys, 2006, 98: 44–50

Hughes D A, Hansen N, Bammann D J. Geometrically necessary boundaries, incidental dislocation boundaries and geometrically necessary dislocations. Scripta Mater, 2003, 48: 147–153

Ananthan V S, Leffers T, Hansen N. Cell and band structure in cold rolled polycrystalline copper. Mater Sci Techn, 1991, 7: 1069–1075

Hansen N. Cold deformation microstructure. Mat Sci Tech, 1990, 6: 1039–1047

Huang X, Hansen N. Grain orientation dependence of microstructure in aluminum deformed in tension. Scripta Mater, 1997, 37: 1–7

Hansen N, Huang X. Microstructure and flow stress of polycrystals and single crystal. Mater Sci Eng A, 1998, 46: 1827–1836

Huang X. Grain orientation effect on microstructure in tensile strained copper. Scripta Mater, 1998, 38: 1697–1703

Hughes D A, Hansen N. High angle boundaries formed by grain subdivision mechanisms. Acta Mater, 1997, 45: 3871–3886

Hughes D A, Hansen N. Microstructure and strength of nickel at large strains. Acta Mater, 2000, 48: 2985–3004

Cao W Q, Godfrey A, Liu Q. EBSP investigation of microstructure and texture evolution during equal channel angular pressing of aluminum. Mater Sci Eng A, 2003, 361: 9–14

Huang X, Tsuji N, Hansen N, et al. Microstructual evolution during accumulative roll-bonding of commercial purity aluminum. Mater Sci Eng A, 2004, 340: 265–271

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Yan, W., Li, B. et al. Microstructure and texture evolution of cold drawing 〈110〉 single crystal copper. Sci. China Technol. Sci. 54, 1551–1559 (2011). https://doi.org/10.1007/s11431-011-4349-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4349-5