Abstract

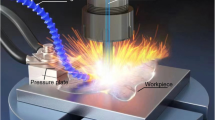

Insulating ceramics are applied to modern manufacturing industries for their improved material properties. But they are the difficult-to-machine materials because of their high rigidity, high brittleness and non-electrical conductivity. A new method which employs a high energy capacitor for electric discharge machining of insulating ceramics efficiently is presented in this paper, and the single discharge experiments have been carried out. The process uses the high voltage, large capacitor and high discharge energy, it is able to effectively machine insulating ceramics, and the single discharge crater volume of insulating ceramics can reach 17.63 mm3. The effects of polarity, peak voltage, capacitance, current-limiting resistance, tool electrode feed, tool electrode section area and assisting electrode thickness on the process performance such as the single discharge crater volume, the tool wear ratio and the assisting electrode wear ratio have been investigated. The microstructure of the discharge crater is examined with a scanning electron microscope (SEM). The results show that the discharge craters have sputtering appearance, the insulating ceramic materials are mostly removed by spalling, in the center region of the discharge some materials are removed by melting and vaporization, and the material removal is enhanced with the machining parameters increasing.

Similar content being viewed by others

References

Lorenzo-Martin C, Ajayi O O, Singh D, et al. Friction and wear behavior of zirconia ceramic materials. Ceram Eng Sci Proc, 2009, 29(4): 75–84

Bandyopadhyay W S, Biswas S K, Maiti H S. Nitride & oxy-nitride ceramics for high temperature and engineering applications. Key Eng Mat, 2009, 395: 193–208

Luo H H, Zhang F C, Wang T S. Prediction of fracture characteristic of particle-reinforced alumina-based composites. Sci China Ser E-Tech Sci, 2009, 52(4): 864–870

Tian X L, Yang J F, Liu C, et al. Research progress of advanced machining technologies for engineering ceramics. Adv Mater Res, 2009, 69–70: 359–363

Guo L, Xie G Z, Li B. Grinding temperature in high speed deep grinding of engineering ceramics. Int J Abras Technol, 2009, 2(3): 245–258

Arai S, Wilson S A, Corbett J, et al. Ultra-precision grinding of PZT ceramics-surface integrity control and tooling design. Int J Mach Tools Manuf, 2009, 49(12–13): 998–1007

Mehta R C S, Jadoun R S, Kumar P, et al. Application of Taguchi method in the optimization of process parameters for conicity of holes in ultrasonic drilling of engineering ceramics. Ceram Eng Sci Proc, 2008, 28(7): 167–178

Churi N J, Pei Z J, Shorter D C, et al. Rotary ultrasonic machining of dental ceramics. Int J Mach Mach Mater, 2009, 6(3–4): 270–284

Samant A N, Dahotre N B. Laser machining of structural ceramics—A review. J Eur Ceram Soc, 2009, 29(6): 969–993

Kacar E, Mutlu M, Akman E, et al. Characterization of the drilling alumina ceramic using Nd: YAG pulsed laser. J Mater Process Technol, 2009, 209(4): 2008–2014

Guo Y F, Deng G Q, Bai J C, et al. Electrical Discharge Machining (EDM) phenomena of insulating ZrO2 ceramics with assisting electrode. Key Eng Mat, 2008, 375–376: 313–317

Liu Y H, Ji R J, Li X P, et al. Effect of machining fluid on the process performance of electric discharge milling of insulating Al2O3 ceramic. Int J Mach Tools Manuf, 2008, 48(9): 1030–1035

Yin S H, Ohmori H, Dai Y T, et al. ELID grinding characteristics of glass-ceramic materials. Int J Mach Tools Manuf, 2009, 49(3–4): 333–338

Chak S K, Venkateswara R P. Trepanning of Al2O3 by electrochemical discharge machining (ECDM) process using abrasive electrode with pulsed DC supply. Int J Mach Tools Manuf, 2007, 47(14): 2061–2070

Liu Y H, Jia Z X, Liu J C. Study on hole machining of nonconducting ceramics by gas-filled electrodischarge and electrochemical compound machining. J Mater Process Technol, 1997, 69(1-3): 198–202

Chak S K, Venkateswara R P. The drilling of Al2O3 using a pulsed DC supply with a rotary abrasive electrode by the electrochemical discharge process. Int J Adv Manuf Technol, 2008, 39(7–8): 633–641

Fukuzawa Y, Mohri N, Tani, T. Machining characteristics of insulating ceramics by electrical discharge machine. Ind Ceram, 2001, 21(3): 187–189

Muttamara A, Fukuzawa Y, Mohri N, et al. Probability of precision micro-machining of insulating Si3N4 ceramics by EDM. J Mater Process Technol, 2003, 140(1–3): 243–247

Akio K. MEEC machining of new materials and difficult-to-machine materials. Mach Tools, 1986, 24(12): 82–88

Liu Y H, Ji R J, Li X P, et al. Electric discharge milling of insulating ceramics. Proc Inst Mech Eng Part B J Eng Manuf, 2008, 222(2): 361–366

Liu Y H, Li X P, Ji R J, et al. Effect of technological parameter on the process performance for electric discharge milling of insulating Al2O3 ceramic. J Mater Process Technol, 2008: 208(1–3): 245–250

Cao F G. Electrical Discharge Machining. Beijing: Chemical Industry Press, 2005. 16–18

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ji, R., Liu, Y., Zhang, Y. et al. An experimental research on single discharge machining of insulating ceramics efficiently with high energy capacitor. Sci. China Technol. Sci. 54, 1537–1545 (2011). https://doi.org/10.1007/s11431-011-4327-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4327-y